Preparing method of G10CrNi3Mo bearing steel large-scale special-shaped cross section annular blank

A technology of special-shaped section and bearing steel, which is applied in the field of billet making of ring forgings, can solve the problems of heavy weight, etc., and achieve the effects of reducing forming pressure, controlling flow direction, and ensuring forming size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

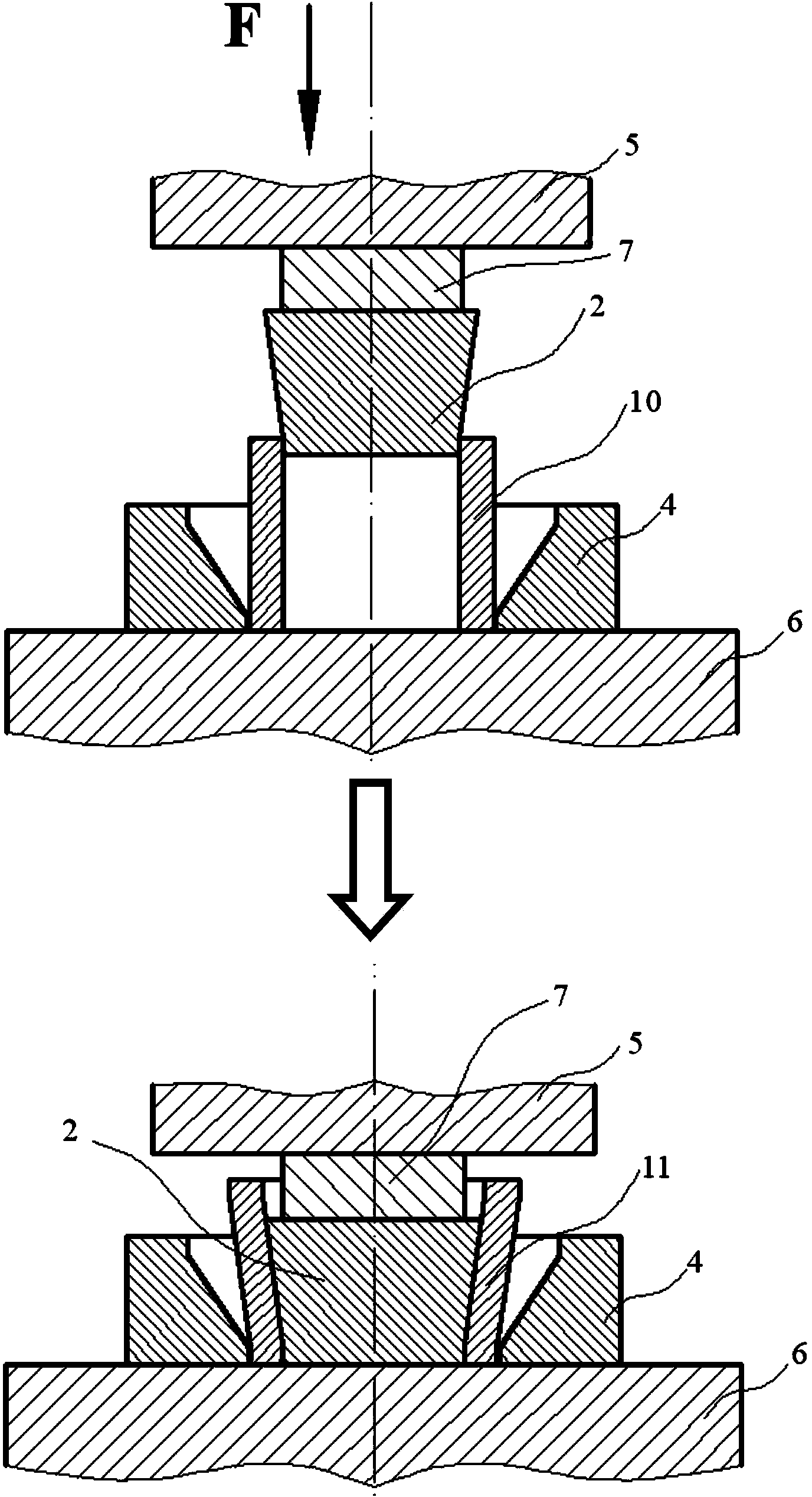

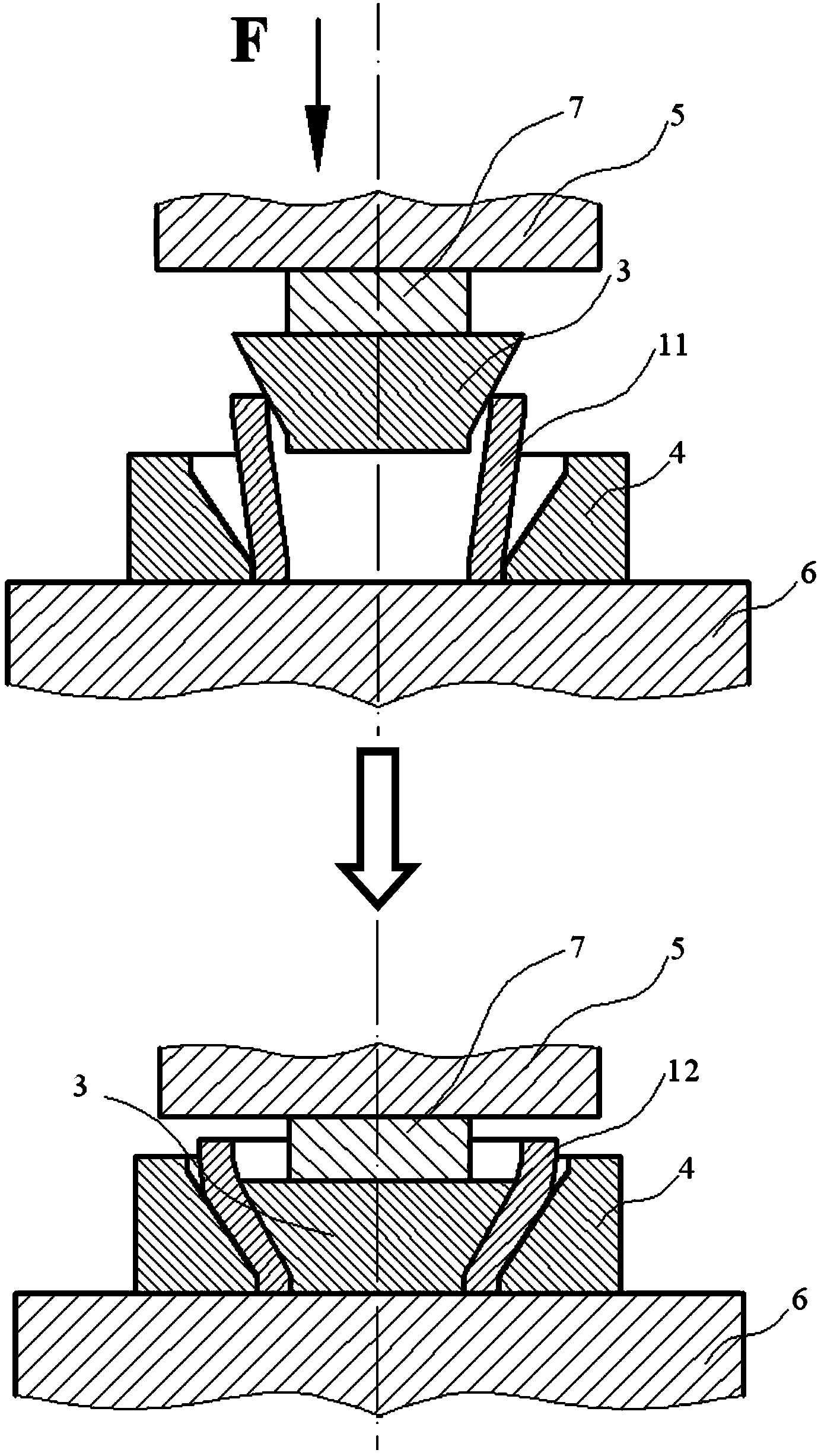

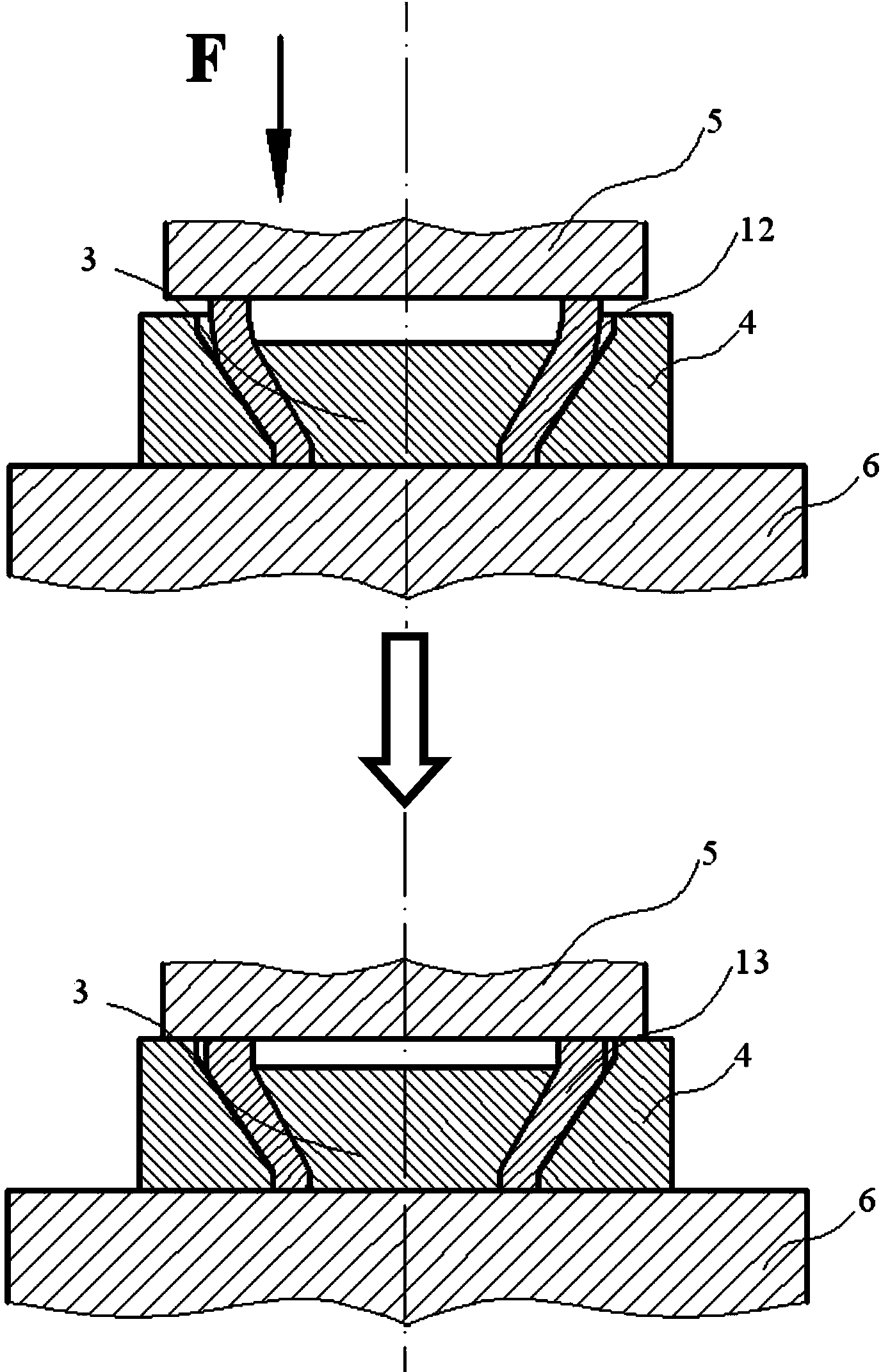

[0022] To carry out the preparation method of the G10CrNi3Mo bearing steel large-scale special-shaped cross-section ring billet described in the present invention, it is necessary to provide equipment such as forging presses, ring rolling mills, and high-temperature electric furnaces. The specific implementation of the method will be described in detail below by taking a large ring forging with a special-shaped cross-section whose material grade is G10CrNi3Mo alloy in my country as an example.

[0023] The process steps of the preparation method of the alloy large-scale special-shaped cross-section ring billet are as follows:

[0024] Step 1: Unloading. According to certain specifications, the raw material is G10CrNi3Mo alloy, and its main chemical element content (weight percentage) is: C content 0.17% ~ 0.25%, Si content 0.17% ~ 0.37%, Mn content 0.30% ~ 0.60%, S content ≤ 0.030%, P content ≤ 0.030%, Cr content 0.60% ~ 0.90%, Ni content 2.75% ~ 3.25%, Cu content ≤ 0.25%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com