Upsetting method and upsetting apparatus

A processing device and processing method technology, applied in metal processing equipment, engine components, mechanical equipment, etc., can solve problems such as damage to product value and poor shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

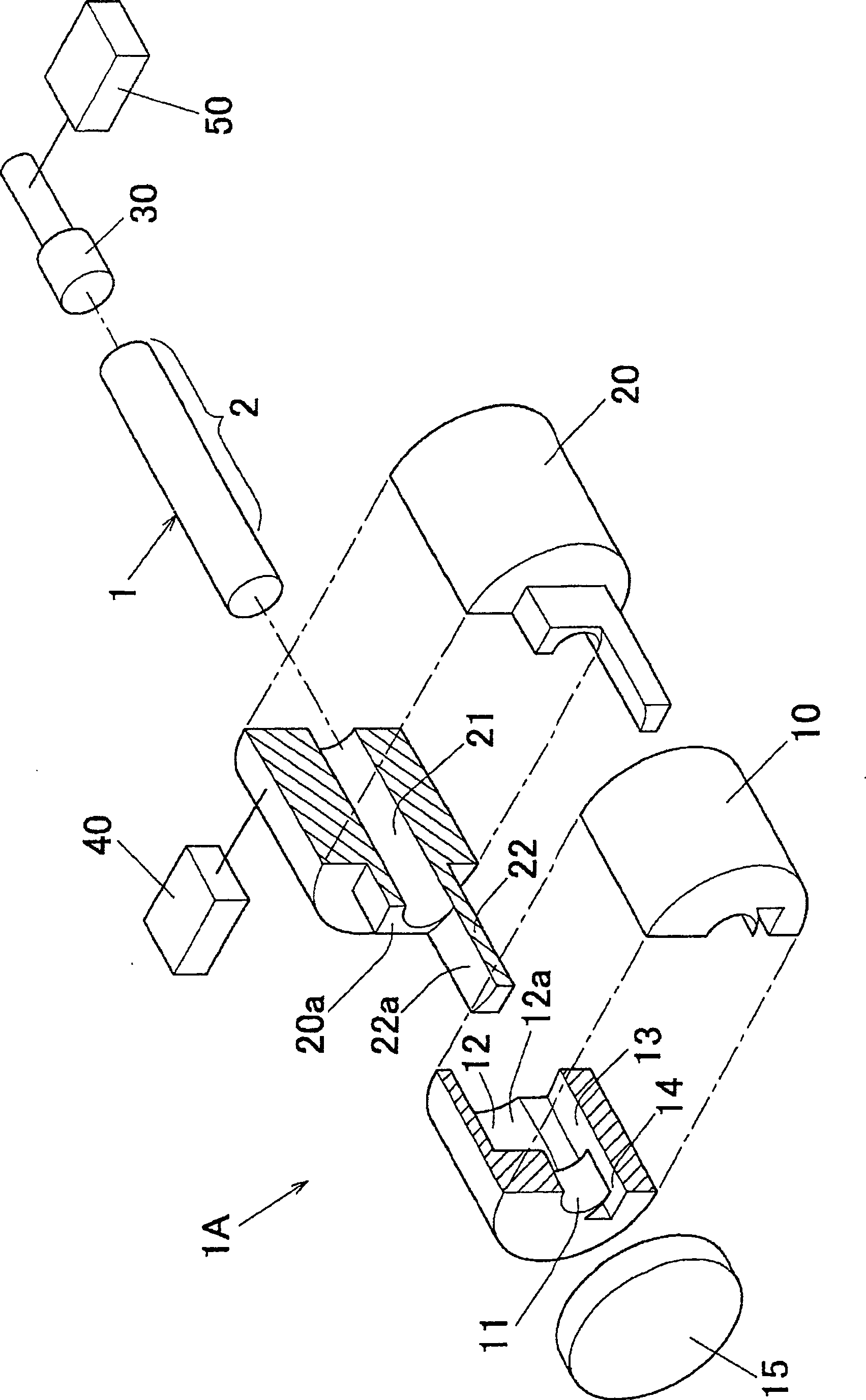

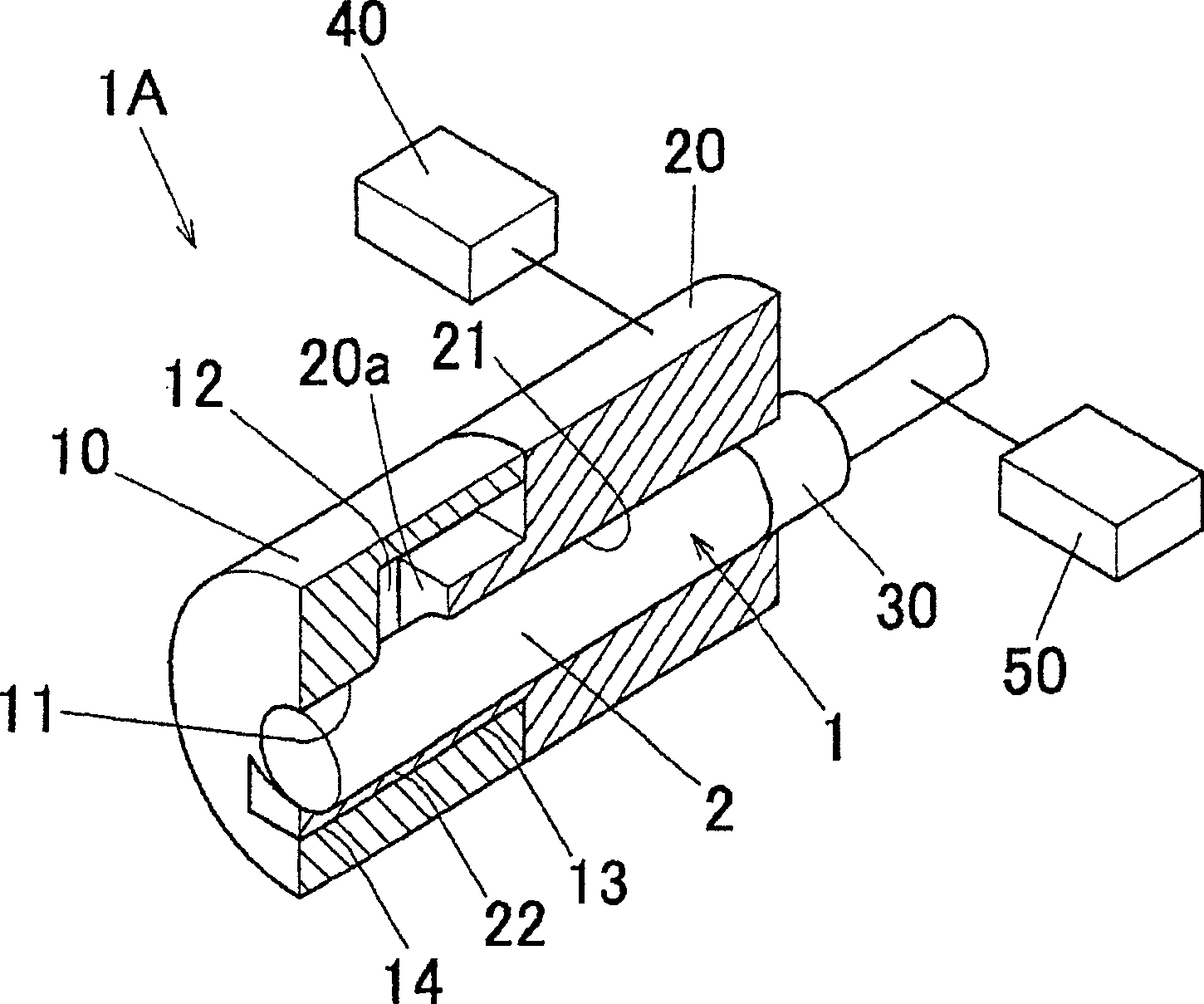

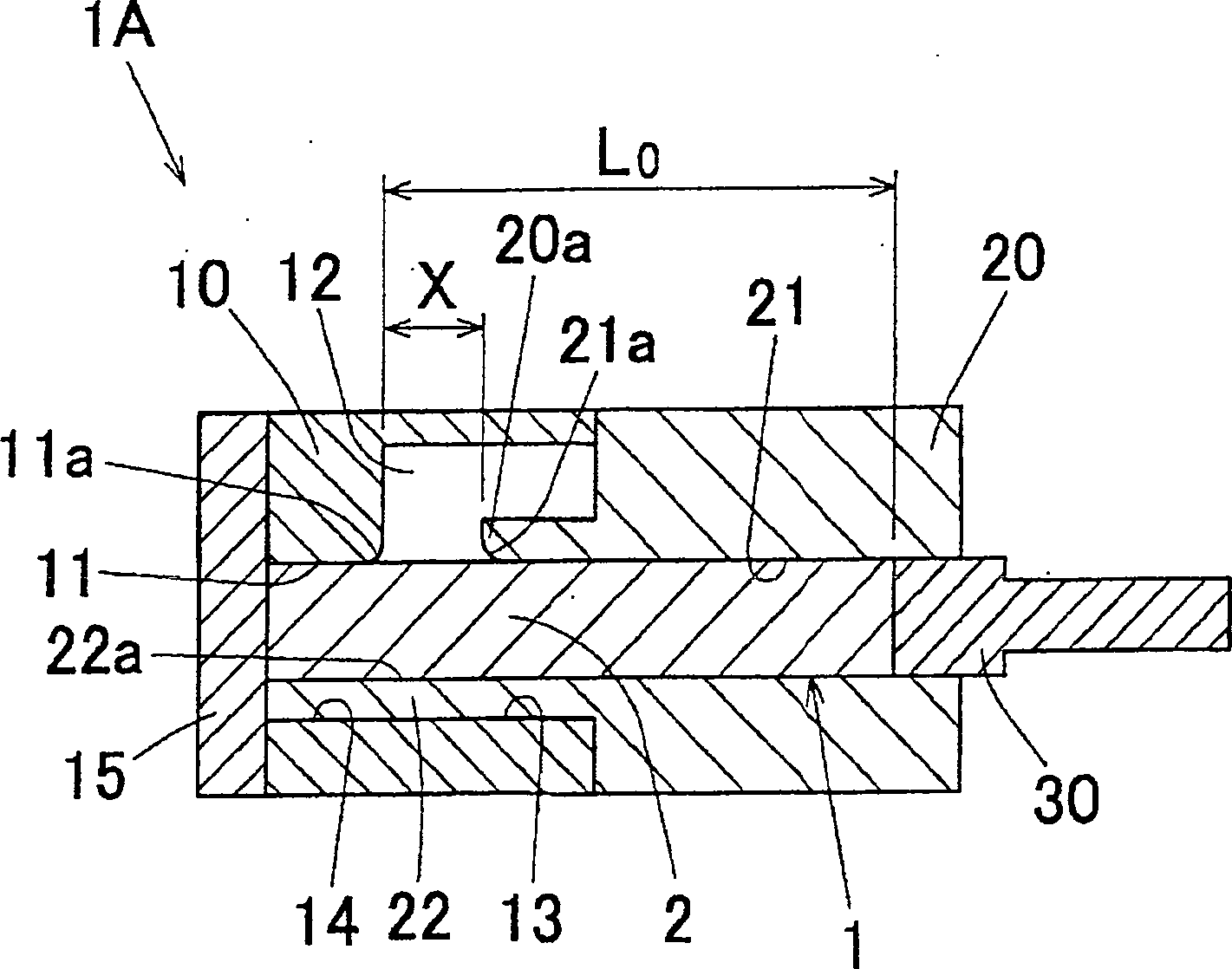

Method used

Image

Examples

Embodiment

[0319] Next, specific examples of the present invention will be shown below. However, the present invention is not limited to the cases shown in this example.

[0320] Prepare a round bar-shaped blank 1 made of continuous casting and rolling parts with a diameter equivalent to 12 mm and a round bar-shaped blank 1 made of extrusions with a diameter of 12 mm produced by the Propezer aluminum wire continuous casting and rolling method . The material of each blank 1 is aluminum alloy of alloy number A6061 in accordance with JIS (Japanese Industrial Standards). Then, these blanks 1 are roughed by using the upsetting apparatus 1D of the fourth embodiment described above. Next, the molding pressure required at that time was investigated. The results are shown in Table 1. In addition, the lengths of the diameter-expanding planned portions 2 of the blank 1 were all 200 mm.

[0321] Table 1

[0322] Types of blanks heating method heating temperature cool down F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com