Preparation method of gh4169 alloy large-scale special-shaped cross-section ring billet

A technology of GH4169, special-shaped section, applied in the field of billet making of annular forgings, to reduce the forming pressure, control the flow direction, and ensure the forming size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

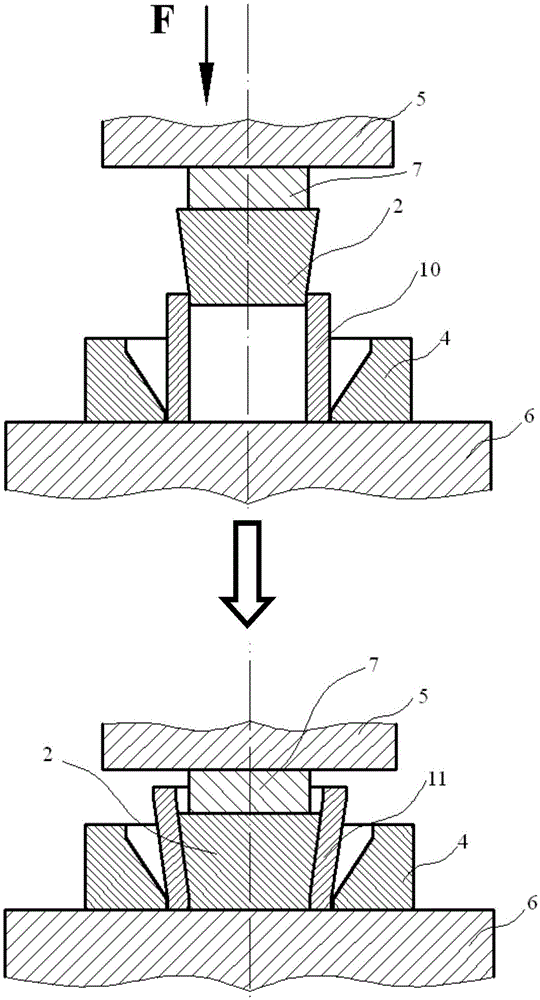

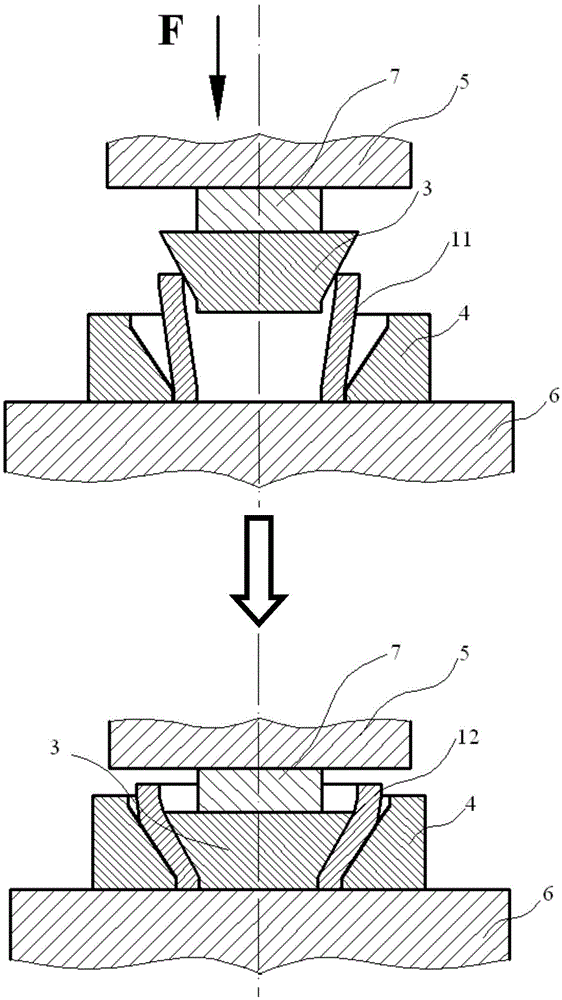

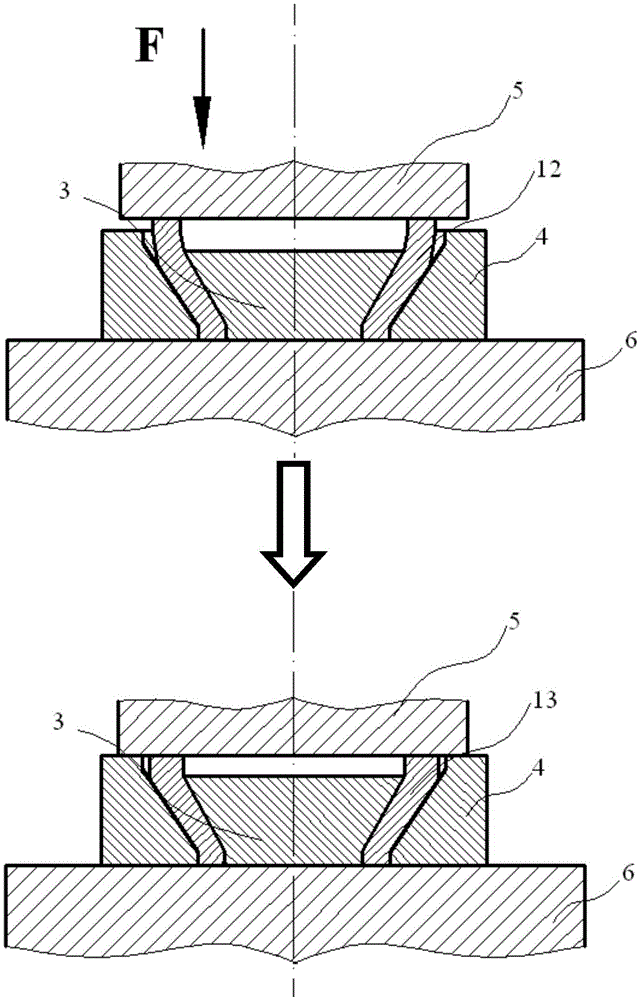

[0023] To implement the preparation method of the GH4169 alloy large ring billet with special-shaped cross-section described in the present invention, it is necessary to provide equipment such as forging presses, ring rolling mills, and high-temperature electric furnaces. The specific implementation of the method will be described in detail below by taking the low-pressure turbine casing special-shaped cross-section ring forging whose material grade is GH4169 alloy in my country as an example.

[0024] The process steps of the preparation method of the alloy large-scale special-shaped cross-section ring billet are as follows:

[0025] Step 1: Unloading. According to certain specifications, the raw material is GH4169 alloy, and its main chemical element content (weight percentage) is: C content ≤ 0.08%, Cr content 17.0% ~ 21.0%, Ni content 50.0% ~ 55.0%, Co content ≤1.0%, Mo content 2.80%~3.30%, Al content 0.30%~0.70%, Ti content 0.75%~1.15%, Nb content 4.75%~5.50%, B content≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com