Lower cone forming tool and method for intervention nail pulling dual-taper bush

A forming tool and double-taper technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as poor quality, unqualified size, and unstable forming of thin-walled bushings, so as to improve fatigue life and solve forming problems. Unstability and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Taking the lower taper forming of the double-tapered bushing with -5 specification interference pulling nails as an example, it can be realized through the following steps:

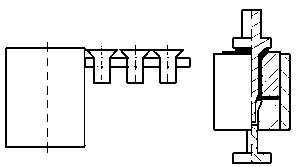

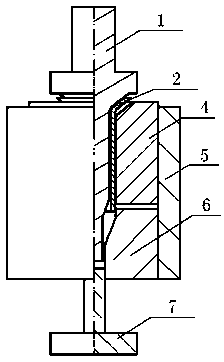

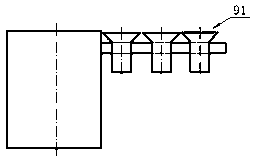

[0044] Step 1: Commissioning equipment includes feeding mechanism, lower cone forming mechanism and unloading mechanism, select -5 specification lower cone forming mold, clamp the inner cavity surface pressure head of double taper bushing on the equipment, double taper bushing The sleeve blank is loaded into the mold through the feeding mechanism.

[0045] The second step: adjust the lower cone forming mechanism, fix the guide sleeve 5 first, and then install the lower cone die 6 and the double-taper bush interlayer sleeve 4 into the guide sleeve 5 successively.

[0046] Step 3: withdraw the top 71 of the unloading mechanism to a position flush with the lower end surface of the lower cone die 6 .

[0047] Step 4: Adjust the inner cavity pressure head 1 of the double-taper bushing so that it is coa...

Embodiment 2

[0054] Taking the lower taper forming of the double-taper bushing with -6 specification interference pulling nails as an example, it can be realized through the following steps:

[0055] Step 1: Commissioning equipment includes feeding mechanism, lower cone forming mechanism and unloading mechanism, select -6 specification lower cone forming mold, clamp the inner cavity surface pressure head of double taper bushing on the equipment, double taper bushing The sleeve blank is loaded into the mold through the feeding mechanism.

[0056] The second step: adjust the lower cone forming mechanism, fix the guide sleeve 5 first, and then install the lower cone die 6 and the double-taper bush interlayer sleeve 4 into the guide sleeve 5 successively.

[0057] Step 3: withdraw the upper end surface 71 of the unloading mechanism to a position flush with the lower end surface of the lower cone die 6 .

[0058] Step 4: Adjust the inner cavity pressure head 1 of the double-taper bushing so th...

Embodiment 3

[0065] Taking the lower taper forming of the double-taper bushing with -8 specifications as an example, it can be realized through the following steps:

[0066] Step 1: Debugging equipment includes feeding mechanism, lower cone forming mechanism and unloading mechanism, select -8 specification lower cone forming mold, clamp the inner cavity surface pressure head of double taper bushing on the equipment, double taper bushing The sleeve blank is loaded into the mold through the feeding mechanism.

[0067] The second step: adjust the lower cone forming mechanism, fix the guide sleeve 5 first, and then install the lower cone die 6 and the double-taper bush interlayer sleeve 4 into the guide sleeve 5 successively.

[0068] Step 3: withdraw the upper end surface 71 of the discharge rod to a position flush with the lower end surface of the lower cone die 6 .

[0069] Step 4: Adjust the inner cavity pressure head 1 of the double-taper bushing so that it is coaxial with the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com