Method for automatically monitoring welding contraction deformation of steel structure

A shrinkage deformation and automatic monitoring technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to display shrinkage deformation results in real time, low labor efficiency, delay in construction period, etc., and achieve real-time grasp of stability and quality, The effect of reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

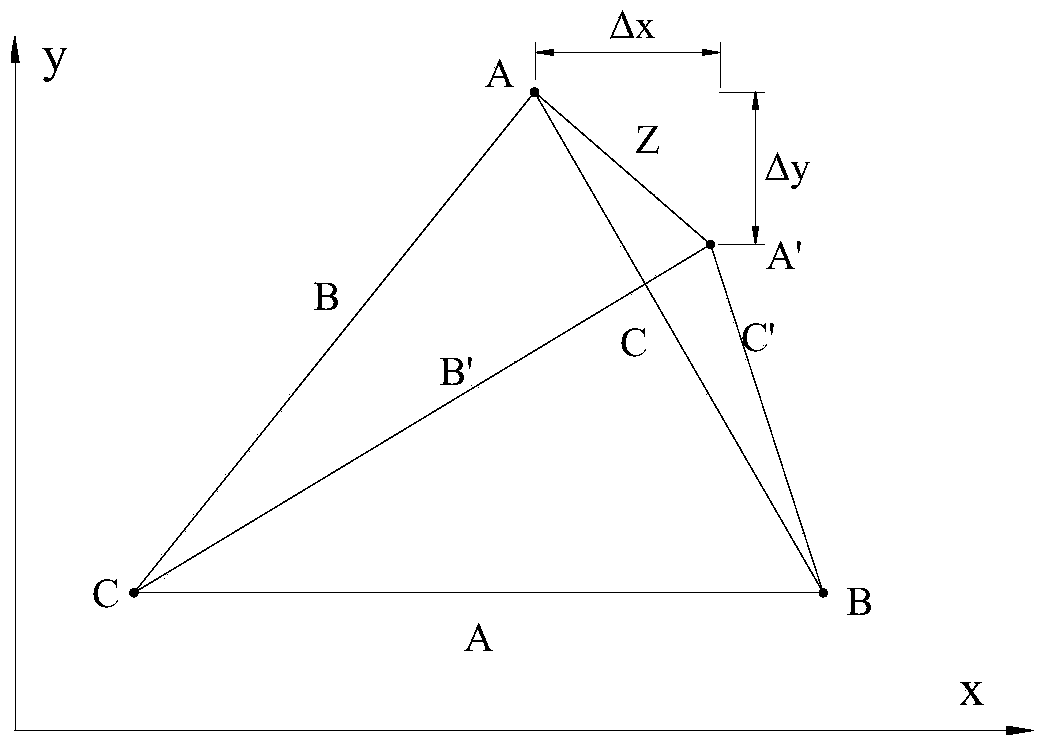

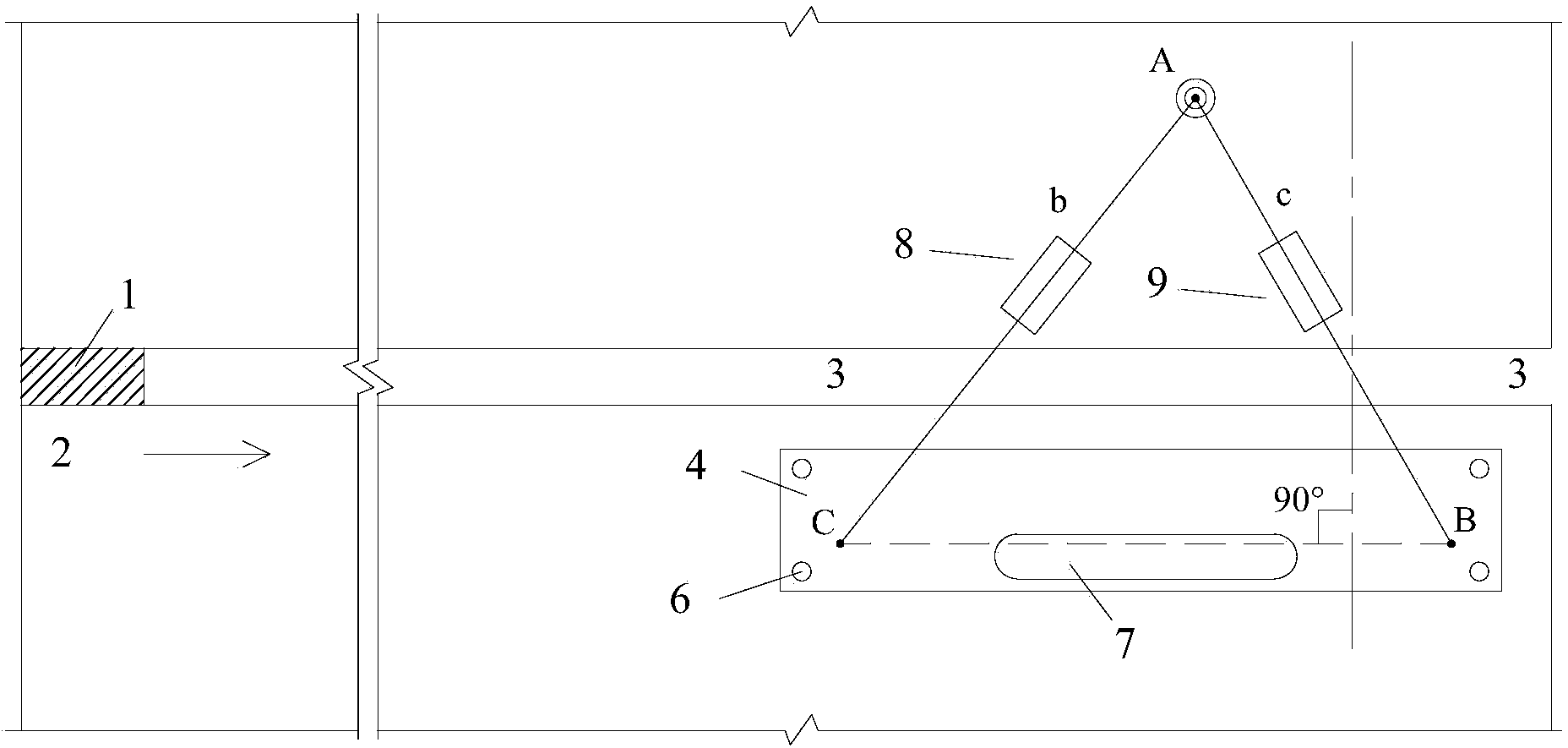

[0031] Such as figure 2 Shown, in the welding process of certain unequal thickness steel plate, apply the present invention as follows:

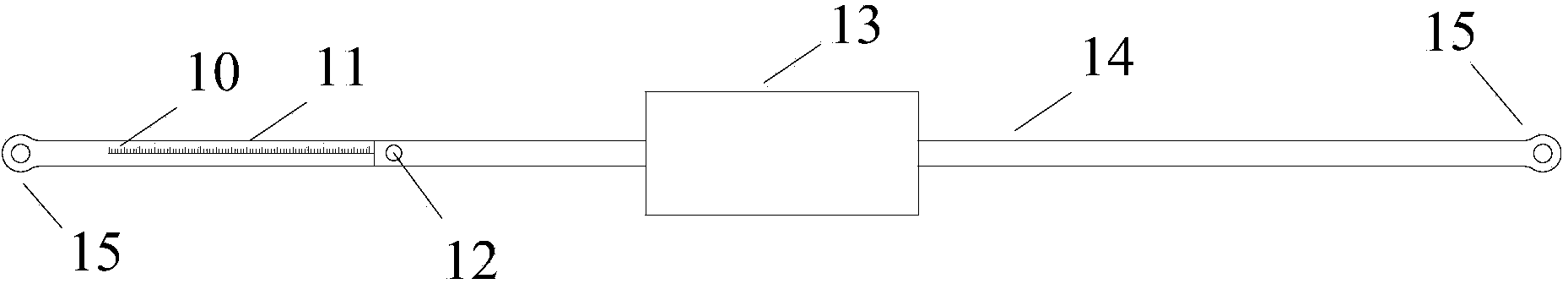

[0032] Among them, the monitoring equipment consists of two displacement sensors b and c (the end of the transmission rod and the support rod of the displacement sensor has a hinge, and the transmission rod has a length adjustment nut and a scale that can directly read the center distance between the two hinges), with a magnet The base A of the fixed sensors b and c, the control display panel and the chassis etc.; the embedded computer has the functions of data processing, storage and real-time display, and can also export the data for processing.

[0033] Install the monitoring equipment at the other end of the starting welding end. Place the chassis of the monitoring equipment parallel to the welding seam on one side of the welded steel plate or component, and place the base A on the other side of the welded steel plate or component. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com