Shear wall formwork inner stay and tie bar combined component and method

A technology of tie bars and inner stays, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, and the construction of buildings, etc. Problems such as loss of internal support force and obstruction of the insertion of the vibrating rod can be achieved to enhance the anti-destructive ability, reduce the difficulty of on-site construction, and improve the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

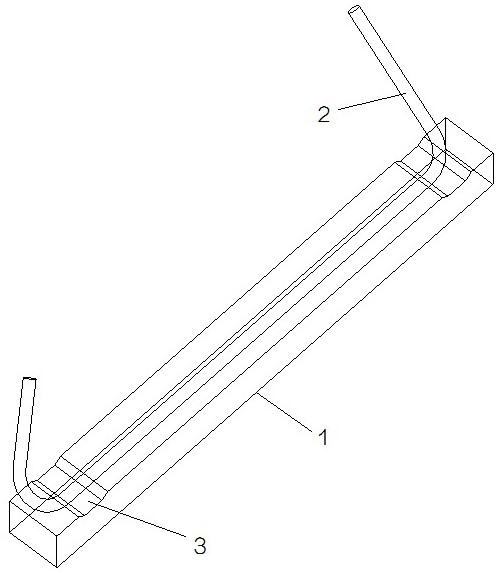

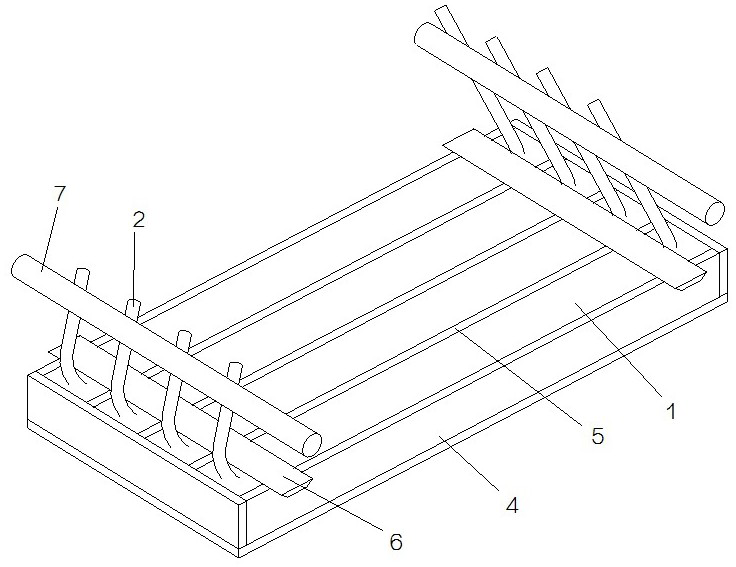

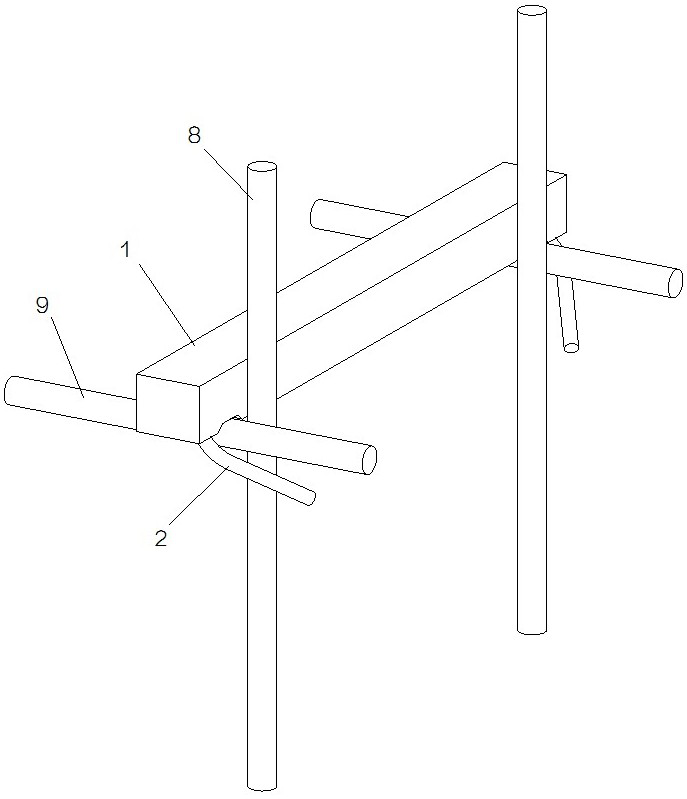

[0028] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as figure 1 shown).

[0029] A kind of shear wall template inner stay and tie bar combined component, it comprises cement inner stay 1 and tie bar 2; Both ends of said tie bar 2 are bent upwards to form a crotch, and one end is 90° hook, the other end is a hook greater than 90° and less than 180°; the cement inner stay 1 is a long strip structure (rectangular cross-section), and a notch 3 is provided on the upper surface of both ends; The middle part of the tie bar 2 is pre-buried in the cement inner stay 1, and the hooks at both ends of the tie tie bar 2 are located on the outside of the corresponding end notch 3 (the center of the cement inner stay 1 is inside, The two ends are outer), and the hooks at the two ends of the tie bar 2 form a certain angle with the upper surface of the cement i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com