Power transmission system

A technology of power transmission system and electric vehicle, which is applied in the direction of power unit, electric power unit, control device, etc., can solve the problems that the reducer is difficult to meet the installation space restriction requirements, the working reliability of the reducer is poor, and the structural stability of the reducer is poor. Achieve the effect of meeting the requirements of installation space constraints, improving structural stability and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present application will be described below in conjunction with the drawings in the embodiments of the present application.

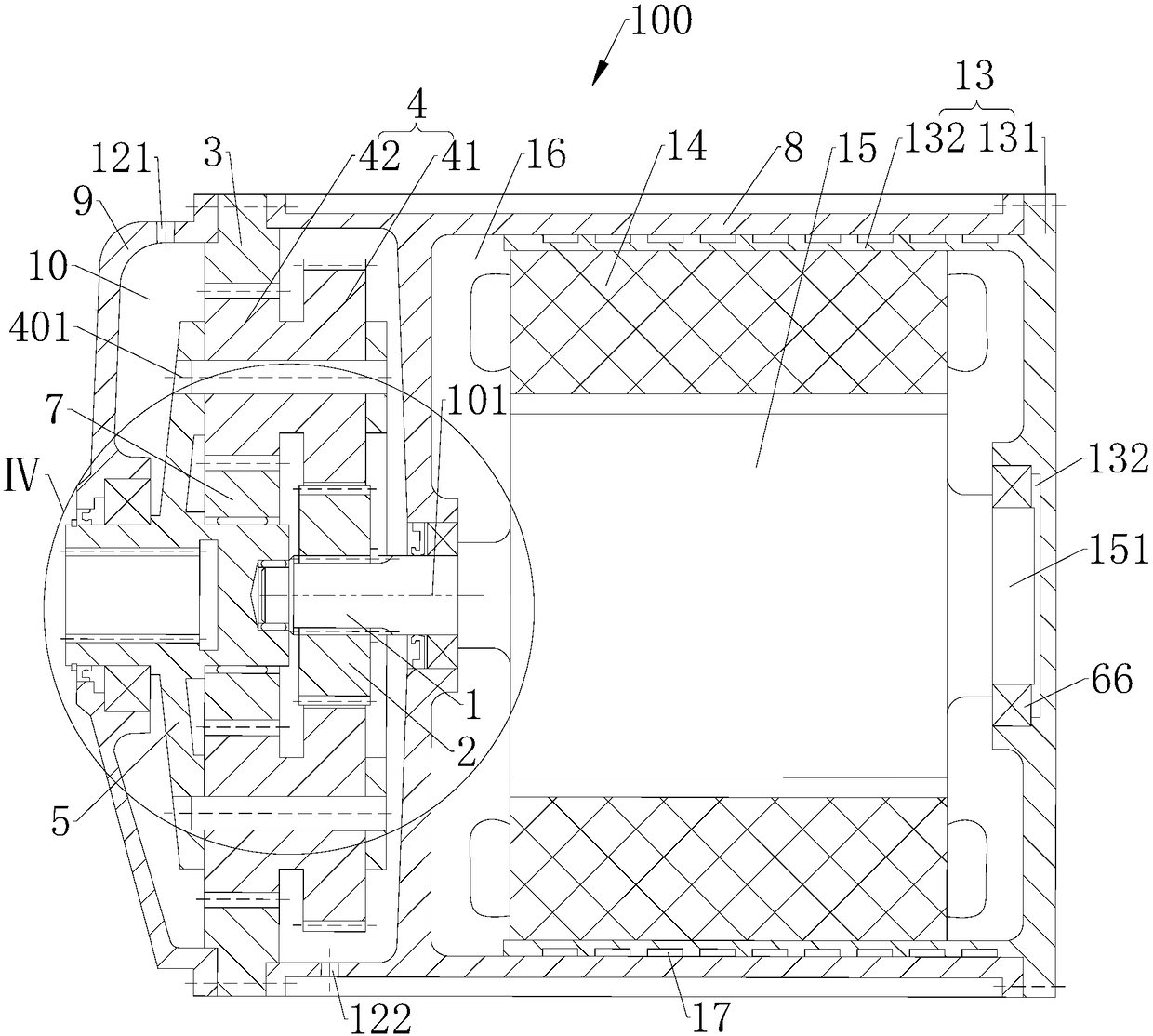

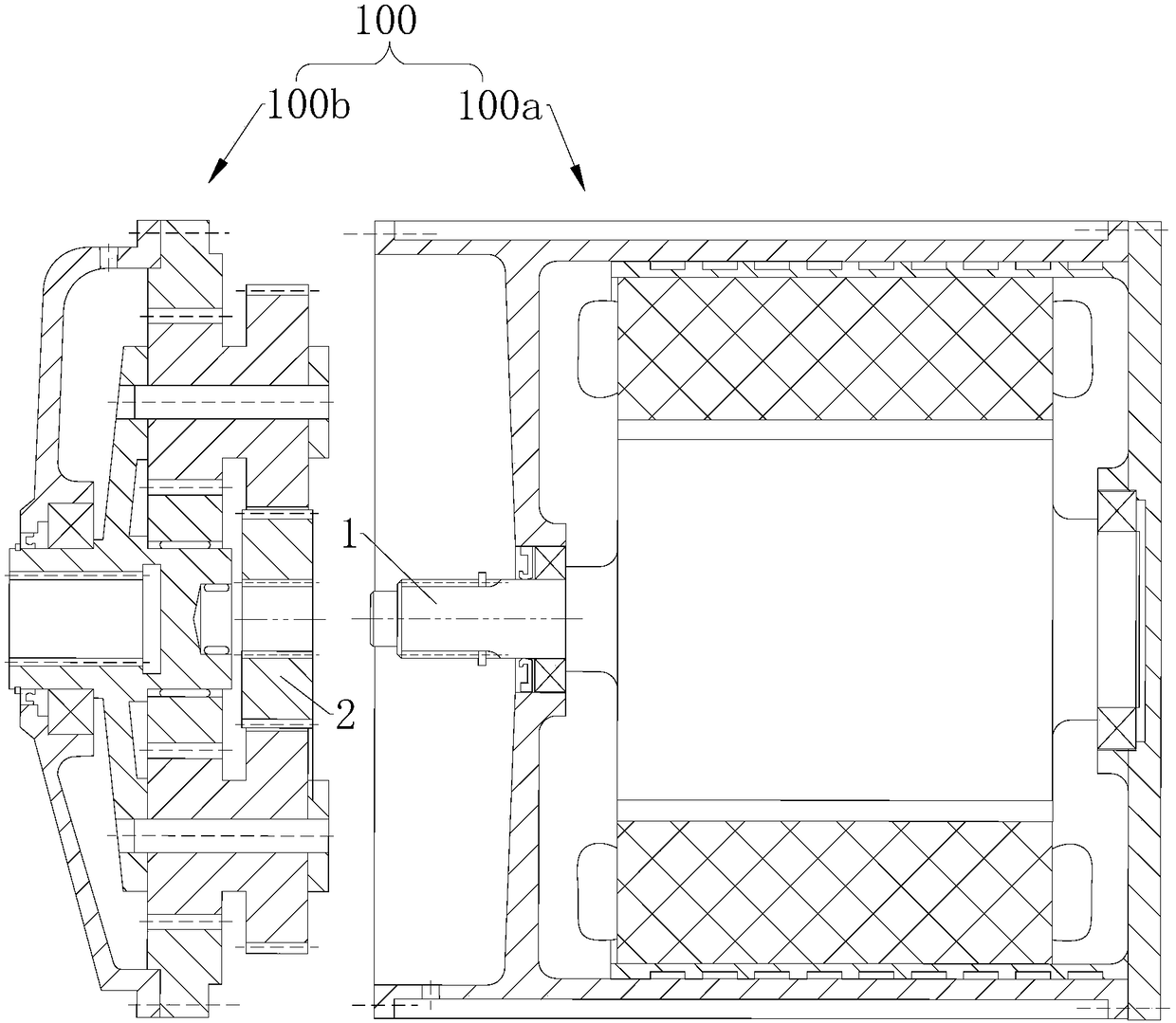

[0049] Please refer to Figure 1 to Figure 4 The embodiment of the present application provides a power transmission system 100, which may be applied to an electric vehicle 200. The power transmission system 100 includes a motor 100a and a reducer 100b. The motor 100 a includes an output shaft 1, and the axis of the output shaft 1 is a first centerline 101. The speed reducer 100b includes a sun gear 2, an inner ring gear 3, a double planetary gear 4 and a planet carrier 5. The sun gear 2 is fixedly sleeved on the outer circumference of the output shaft 1. The ring gear 3 is coaxial with the sun gear 2 and an installation space is formed between the ring gear 3 and the sun gear 2. The double planetary gear 4 is arranged in the installation space. The double planetary gear 4 includes a first gear 41 and a second gear 42 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com