Spring damping delay control device for vacuum toilet related equipment

A technology of spring damping and time-delay control, which is applied to water supply devices, flushing toilets, flushing equipment with water tanks, etc. It can solve the problems of high space occupation rate, poor functionality, poor precision, etc., and achieve fewer types and quantities of parts , compact structure design and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The content of the present invention will be further described in detail below in conjunction with specific embodiments:

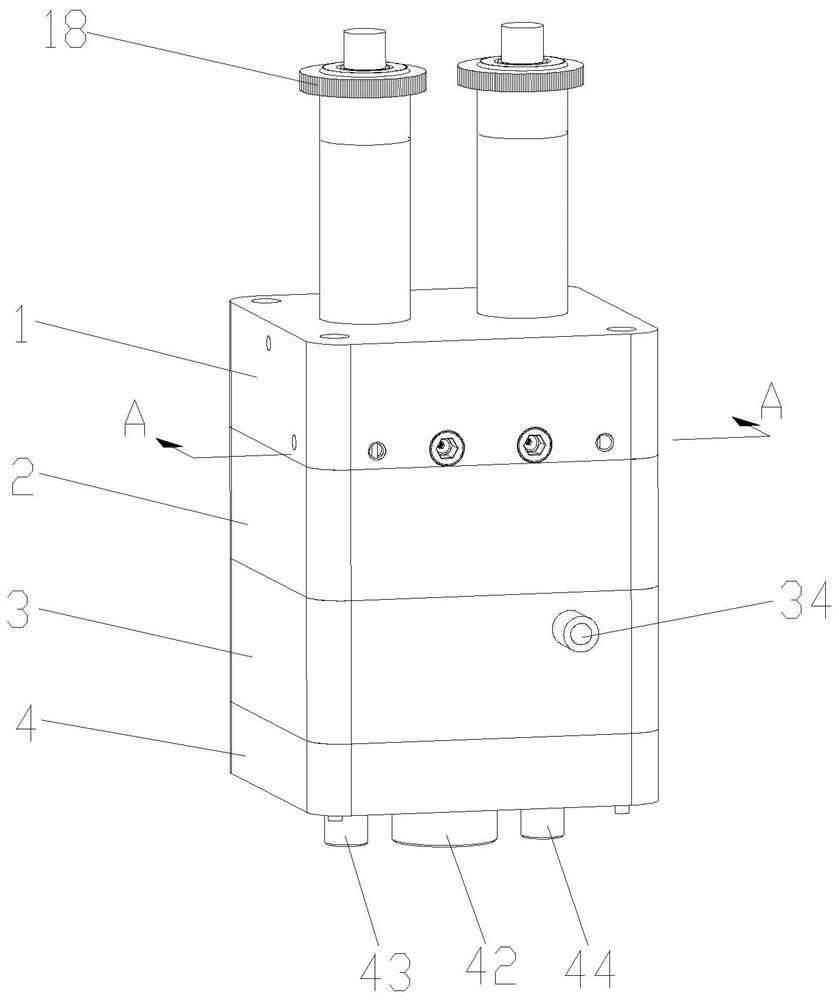

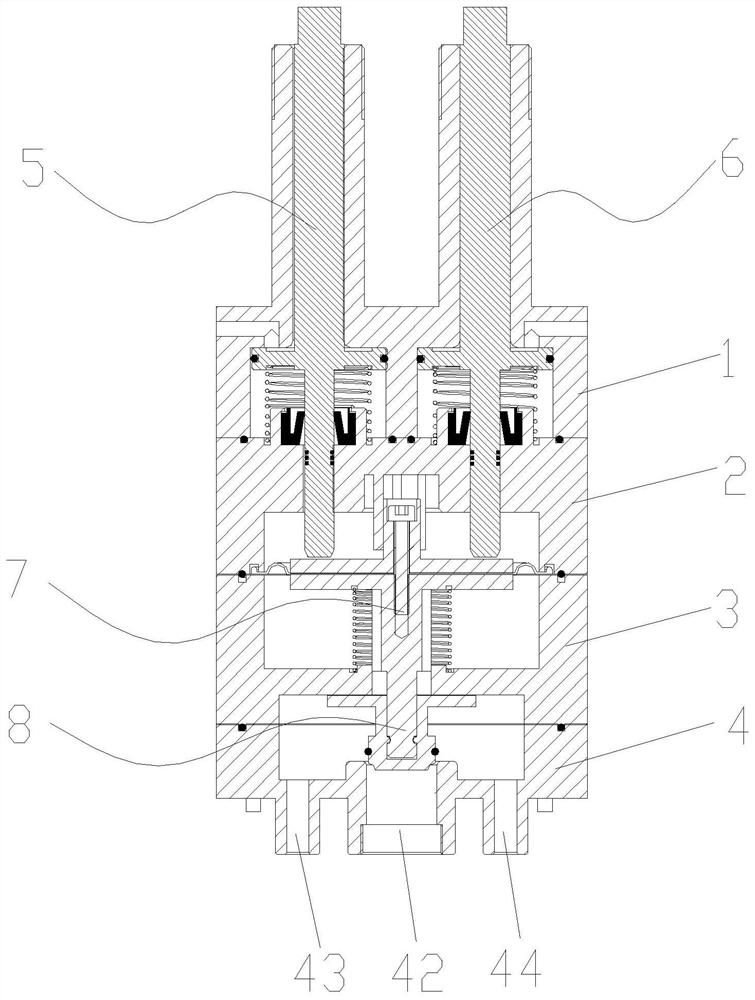

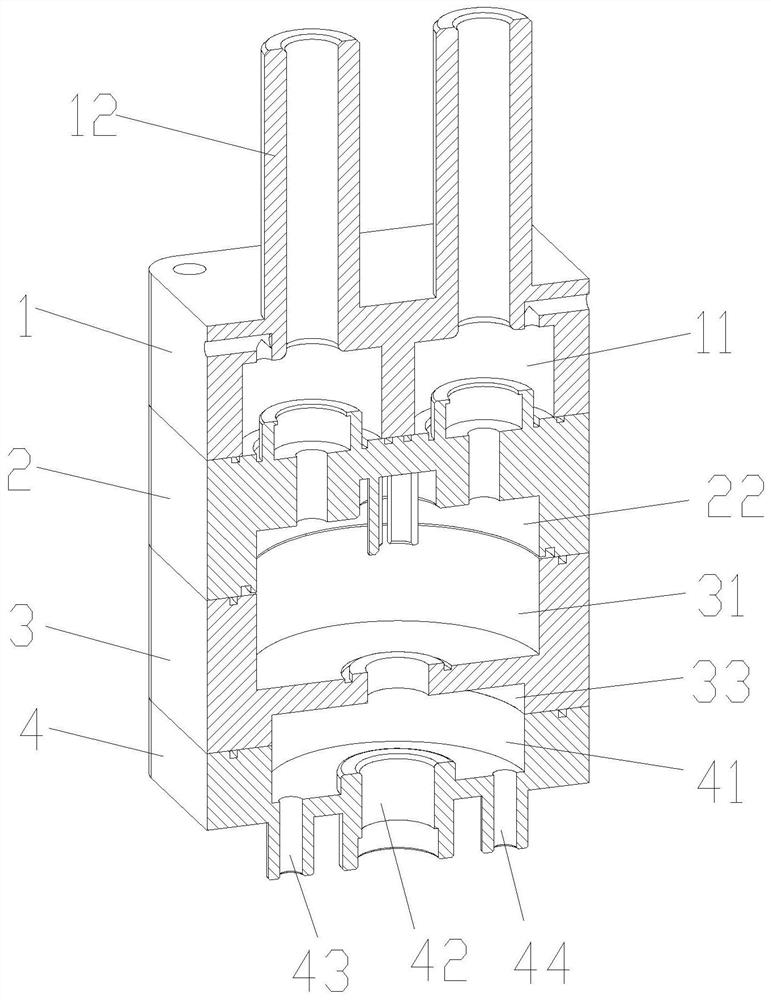

[0057] Such as figure 1 , figure 2 As shown, a spring damping delay control device for vacuum toilet related equipment, wherein vacuum toilet related equipment includes but not limited to vacuum toilets, vacuum urinals and other equipment, the present invention mainly includes input and output units, energy units, power units , Execution unit and control unit; wherein the input and output unit includes a housing, an input interface and an output interface installed on the housing, a control interface for triggering the operation of the energy unit and the control unit; the energy unit includes a large impact installed in the housing The water button assembly 5 and the small flush button assembly 6; the power unit includes a diaphragm assembly 7 installed in the housing and capable of independently controlling the movement of the piston through the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com