Photoresist liquid feeding device and modified set using same

A technology of supplying device and photoresist, which is applied to optics, electrical components, opto-mechanical equipment, etc., can solve the problems of small transportation volume, high purchase cost, and high cost of photoresist liquid products, and avoid supply interruption, concentration Stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0110]

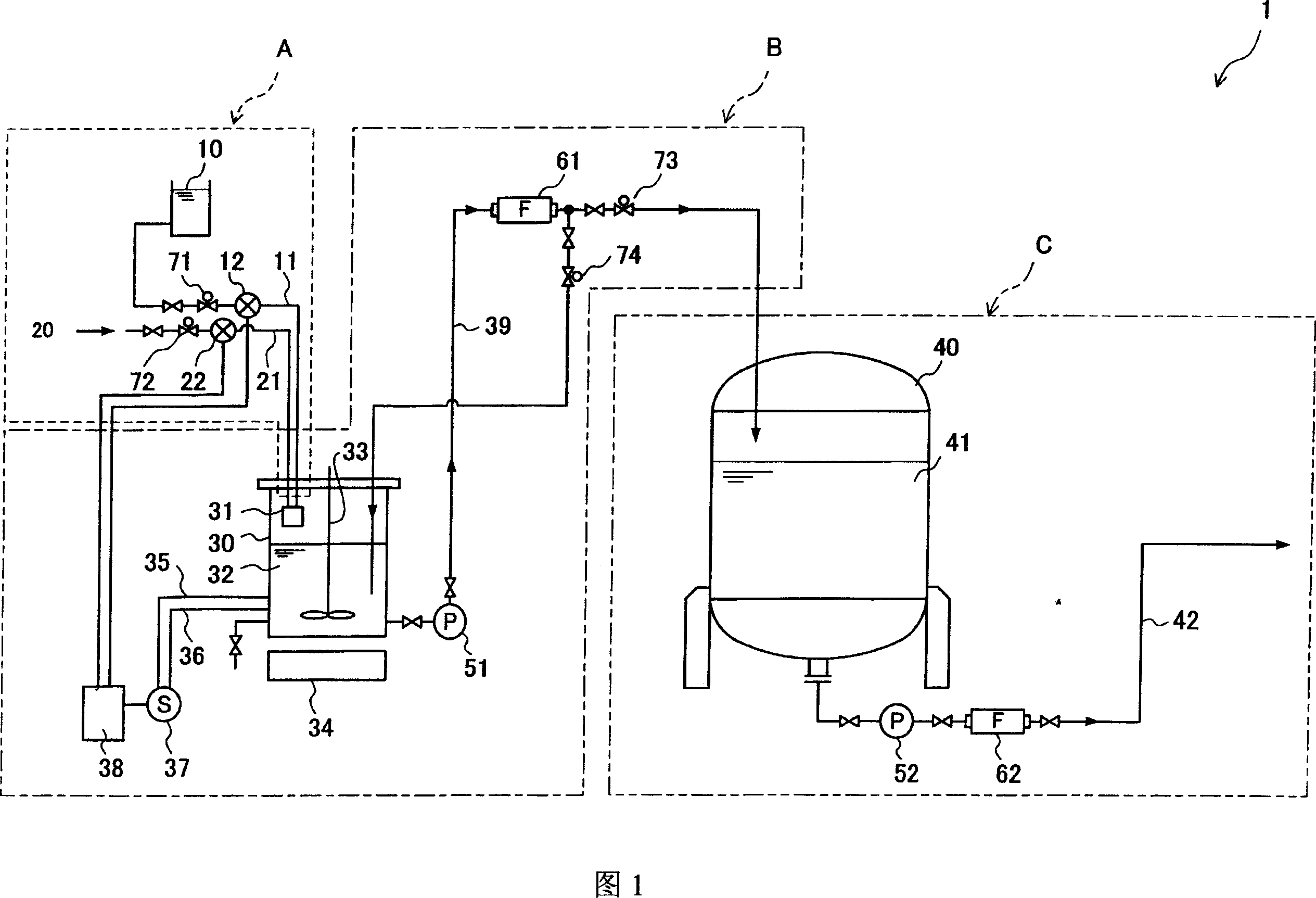

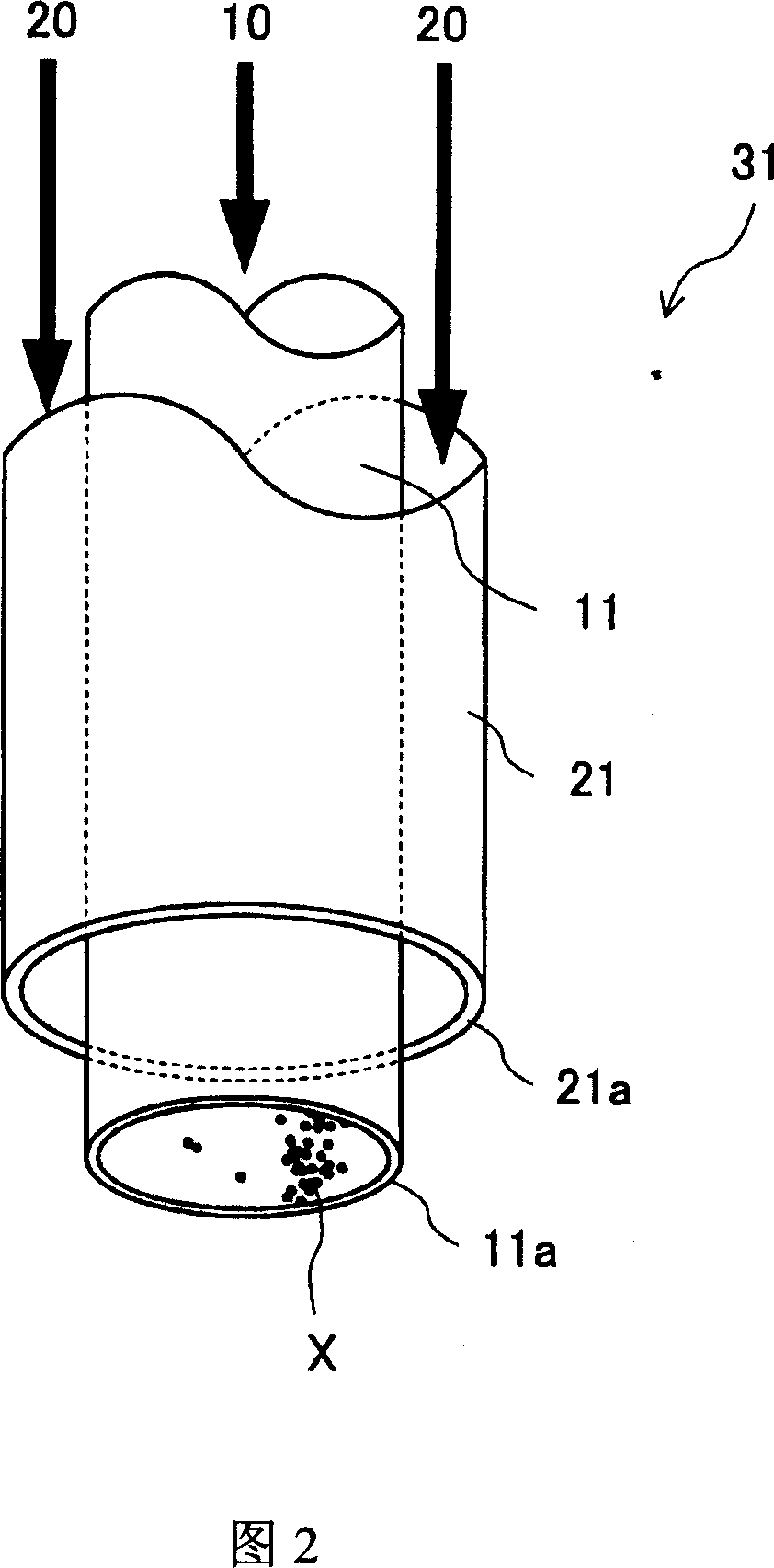

[0111] FIG. 1 is a diagram showing a photoresist solution supply device 1 according to a first embodiment of the present invention. The photoresist solution supply device 1 of the present embodiment has an introduction part A for introducing a high-concentration raw material solution 10, a mixing part B for mixing and stirring the raw material solution 10 introduced into the introduction part A and a solvent 20, and a mixing and stirring part B for mixing and stirring the raw material solution 10 introduced into the introduction part A, and supplying the raw material liquid 10 and the solvent 20 through mixing and stirring. The supply part C of the photoresist solution for the product obtained by mixing and stirring in the part B to adjust the concentration.

[0112] The introduction part A is mainly composed of a raw material liquid introduction line 11 , a raw material liquid flow meter 12 , a solvent introduction line 21 and a solvent flow meter 22 . The mixing p...

no. 2 approach

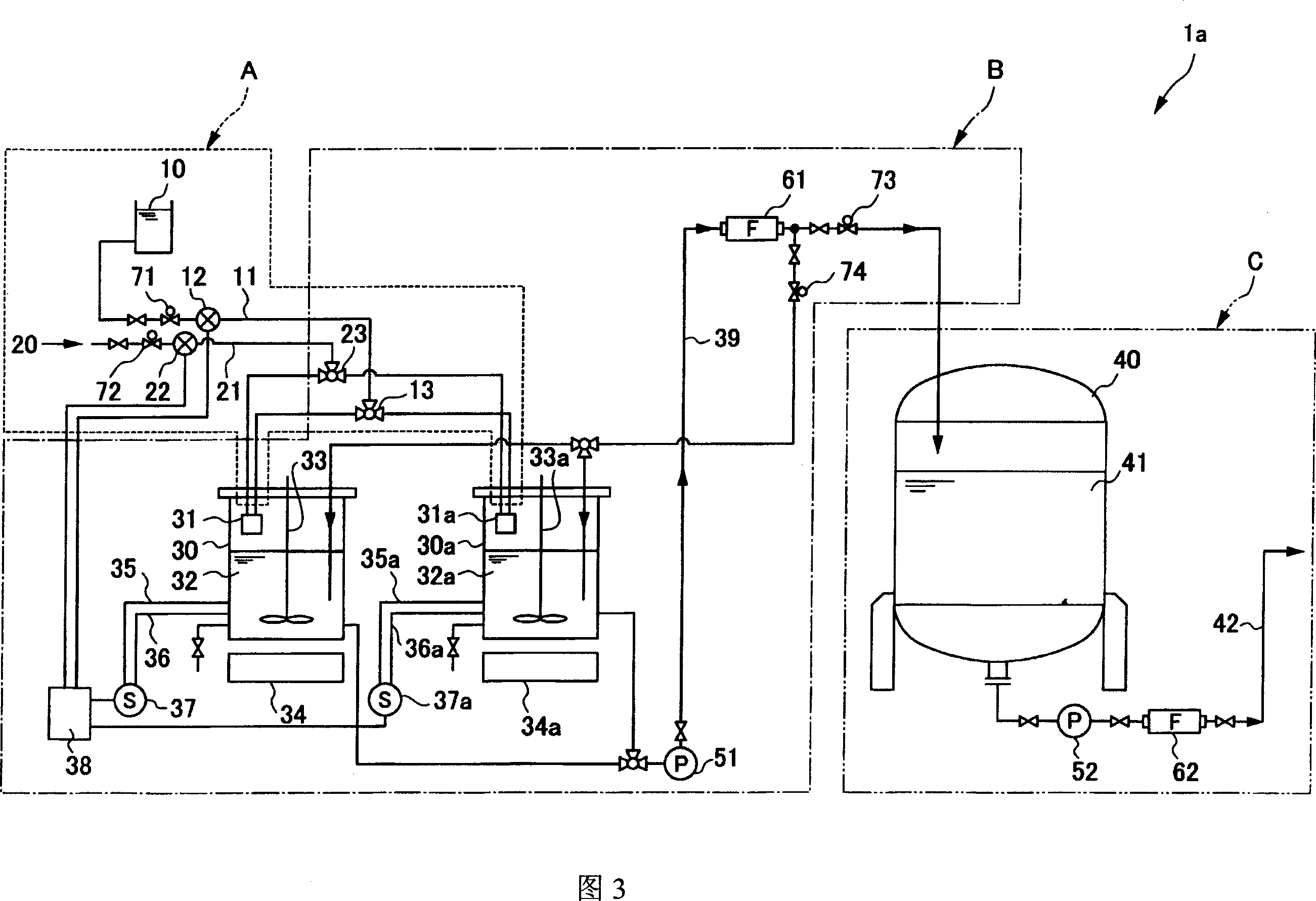

[0208] FIG. 3 is a schematic structural view of a photoresist solution supply device 1 a according to a second embodiment of the present invention. The resist solution supply device 1 a is mainly different from the first embodiment in that a mixing part B thereof has a plurality of mixing tanks.

[0209] [Import Department]

[0210] The structure of the introduction part A related to this embodiment is the same as that of the first embodiment, but the mixing part B has a plurality of mixing tanks 30, 30a. In each of these mixing tanks 30, 30a, the raw material liquid introduction line 11 and the solvent introduction line 21 separated by the three-way valve 13, 23 are connected together. In addition, in Fig. 3, the mixing part B has 2 blending tanks, but there is no limit to the number of blending tanks, the raw material liquid introduction pipeline and the solvent introduction pipeline can only be divided into the number of blending tanks, and combined into each Blending tan...

no. 3 approach

[0222] FIG. 4 is a diagram showing a photoresist solution supply device in a third embodiment of the present invention.

[0223] The photoresist solution supply device 1b has a first mixing tank 30 for coarsely adjusting the concentration of the photoresist solution and a second mixing tank 30b for finely adjusting the concentration of the mixed solution 32 adjusted by the first mixing tank 30 The mixing and stirring part B. In addition, since the introduction part A and the supply part C have the same structure, description is abbreviate|omitted.

[0224] [mixing and stirring department]

[0225] The mixing part B has the 1st mixing tank 30 and the 2nd mixing tank 30b. The structure of each mixing tank is the same as that of the first embodiment, and the same structure is represented by adding b to the same reference numeral.

[0226] [Operation of the mixing section]

[0227] In this embodiment, after the concentration of the mixed liquid is roughly adjusted in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com