TPE material recoverable under stress and deformation at low temperature, its preparation method and use

A deformation and low temperature technology, applied in the field of TPE material and its preparation, to achieve the effect of not easy to wear and deform, good mechanical strength and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

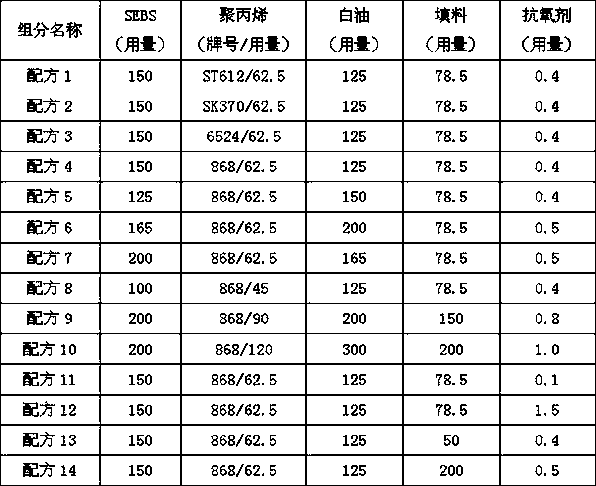

[0020] Weigh each raw material according to the parts by weight of the component formula 1 shown in Table 1, among which 150 parts of SEBS with a weight average molecular weight greater than 80,000 are weighed, 125 parts of white oil with a pour point lower than minus 25°C are weighed, and 125 parts of white oil with a crystallinity lower than 30% grade is 62.5 parts of ST612 high-permeability polypropylene, weigh 78.5 parts of filler, calcium carbonate is used as filler, diatomite, wollastonite, talcum powder, zeolite powder, molecular sieve, carbon black, porous alumina and For one or more of the hollow glass microspheres, weigh 0.4 parts of the antioxidant. The antioxidant is selected from phenols, and one or more mixtures of phosphites and sulfur-containing esters can also be used. All of the above raw materials can be obtained in the market, or can be obtained by using existing technologies.

[0021] Add the prepared SEBS, polypropylene and filler into the mixer, and stir...

Embodiment 2

[0030] TPE particles were prepared according to the composition of formula 2 in Table 1, and the rest of the steps were the same as in Example 1.

Embodiment 3

[0032] TPE particles were prepared according to the composition of formula 3 in Table 1, and the rest of the steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com