Method of Machining Cross Recessed Male Die Using Cold Heading Technology

A process processing and cross groove technology, which is applied in the field of mechanical processing technology, can solve the problems of poor control of the punching shape and depth of the male die, high hardness of the material and difficult processing, and complex shape of the cross groove male die. The effect of shortening, not easy to deform and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

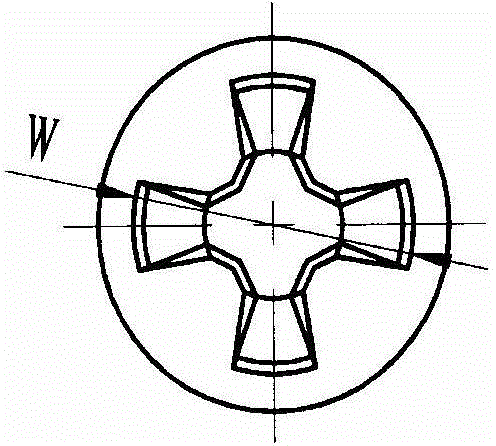

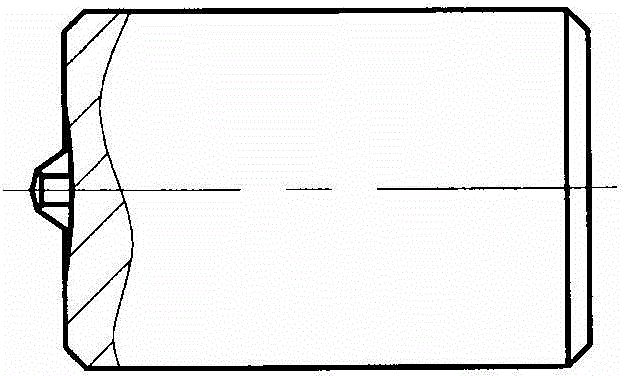

Image

Examples

Embodiment Construction

[0030] The method for processing the cross-recessed male die by the cold heading process includes the following specific steps:

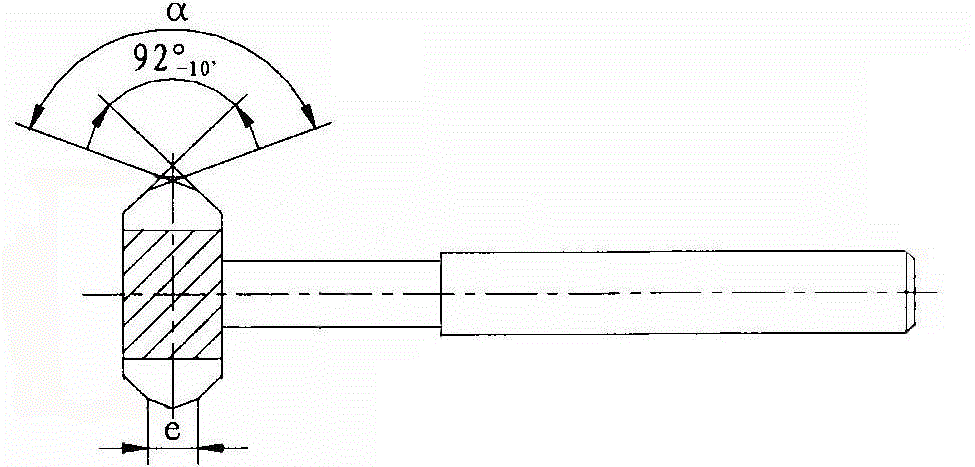

[0031] (1) Processing forming milling cutters, such as image 3 and Figure 4 As shown, it is the same as the commonly used milling cutter. The material is W18Cr4V. The tooth shape processing is completed by milling and sharpening. Guaranteed dimensions α and e of the form milling cutter;

[0032] (2) After roughly milling the cross groove shape of the forming punch with a forming milling cutter, the forming grinding wheel is used to finish machining to remove the allowance, and the dimensions b, e, and f of the forming punch are controlled, and the clamping of the forming punch is realized at the same time. Precise positioning to control the composite angle γ, δ, the material of the forming punch is Cr12MoV, such as Figure 5 to Figure 8 shown;

[0033] (3) Use a forming punch to punch a forming die, and the material of the forming die is also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com