A variable section nozzle ring for a turbocharger

A turbocharger and nozzle ring technology, applied in the direction of machines/engines, stators, engine components, etc., can solve the problems of potential safety hazards, small contact area, easy wear of pins and shift forks, etc., and achieve high reliability, Not easy to wear and deform, high transmission reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

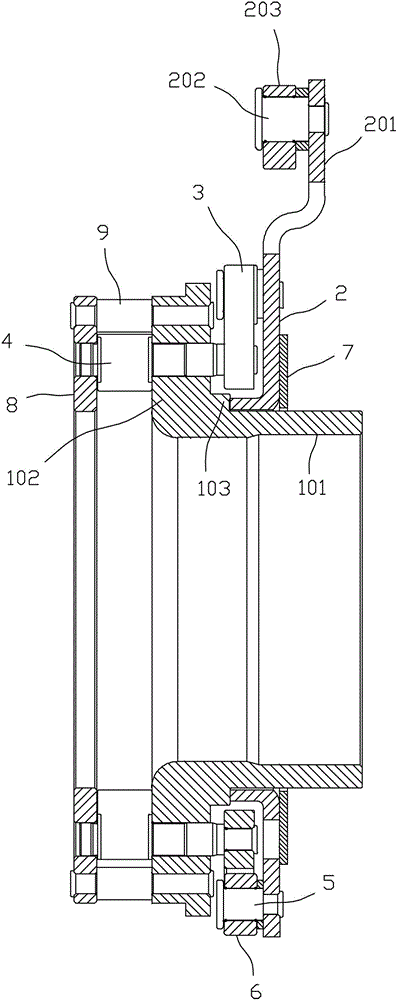

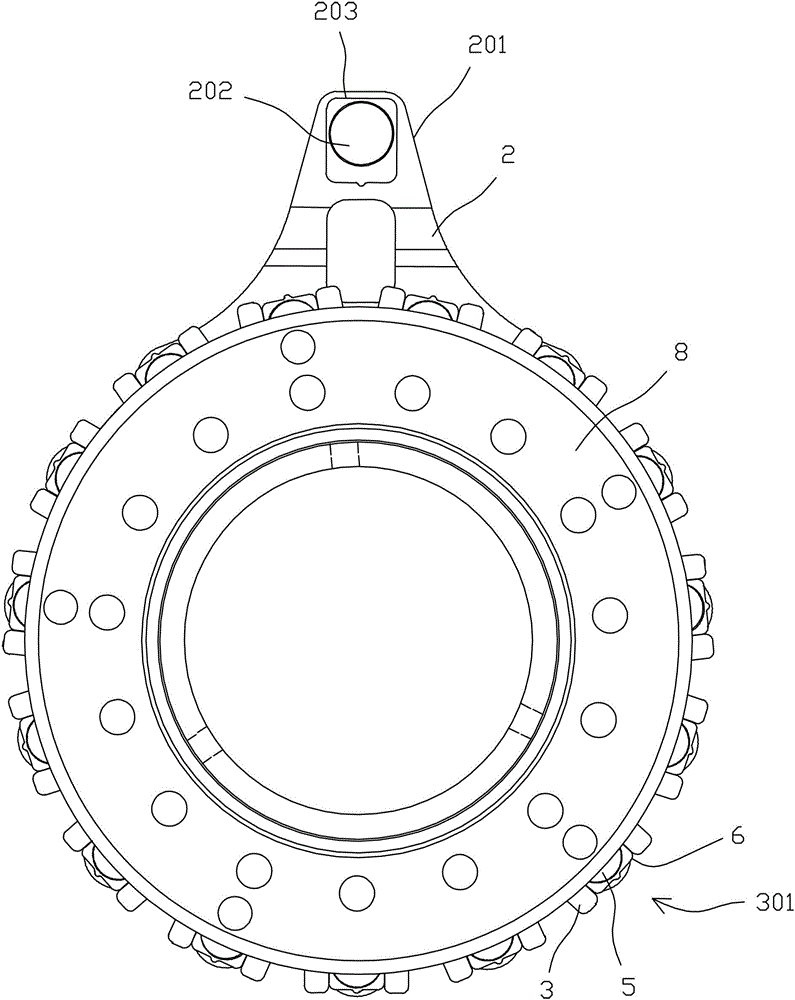

[0018] Depend on figure 1 , figure 2 As shown, the variable-section nozzle ring for a turbocharger of the present invention includes a mounting plate 1 , a dial 2 , a plurality of shift forks 3 and a plurality of pin shafts 5 connected to the dial 2 .

[0019] The mounting plate 1 includes a cylindrical portion 101 and an annular portion 102 extending radially outward from one end of the cylindrical portion 101. The cylindrical portion 101 and the annular portion 102 are formed integrally. When ringing, the cylindrical part 101 is inserted into the installation hole of the turbocharger and fixed.

[0020] The dial 2 is rotatably sleeved on the cylindrical portion 101, and a stop washer 7 for axially positioning the dial 2 is sleeved and fixed on the cylindrical portion 101, that is to say, in An annular boss 103 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com