Embossing relief printing plate, machining process thereof and printing machine with embossing relief printing plate

A printing machine and embossing technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of narrow application range, insufficient three-dimensional effect of patterns, and easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

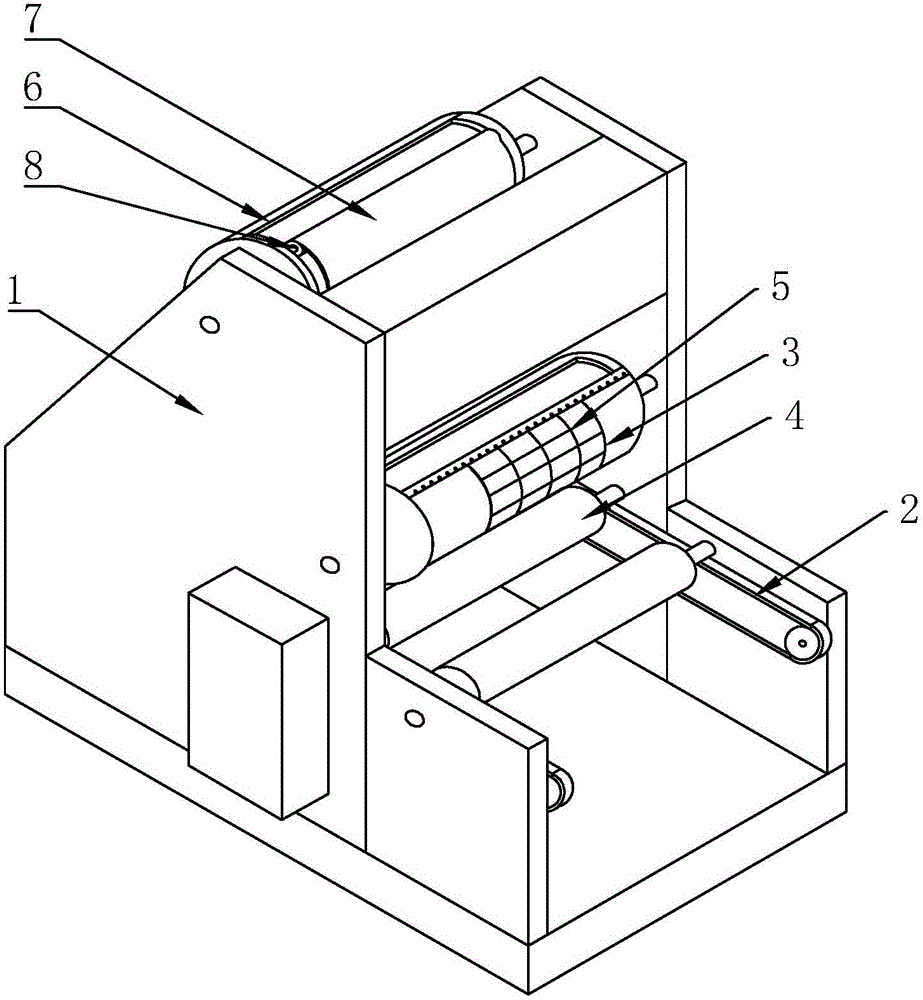

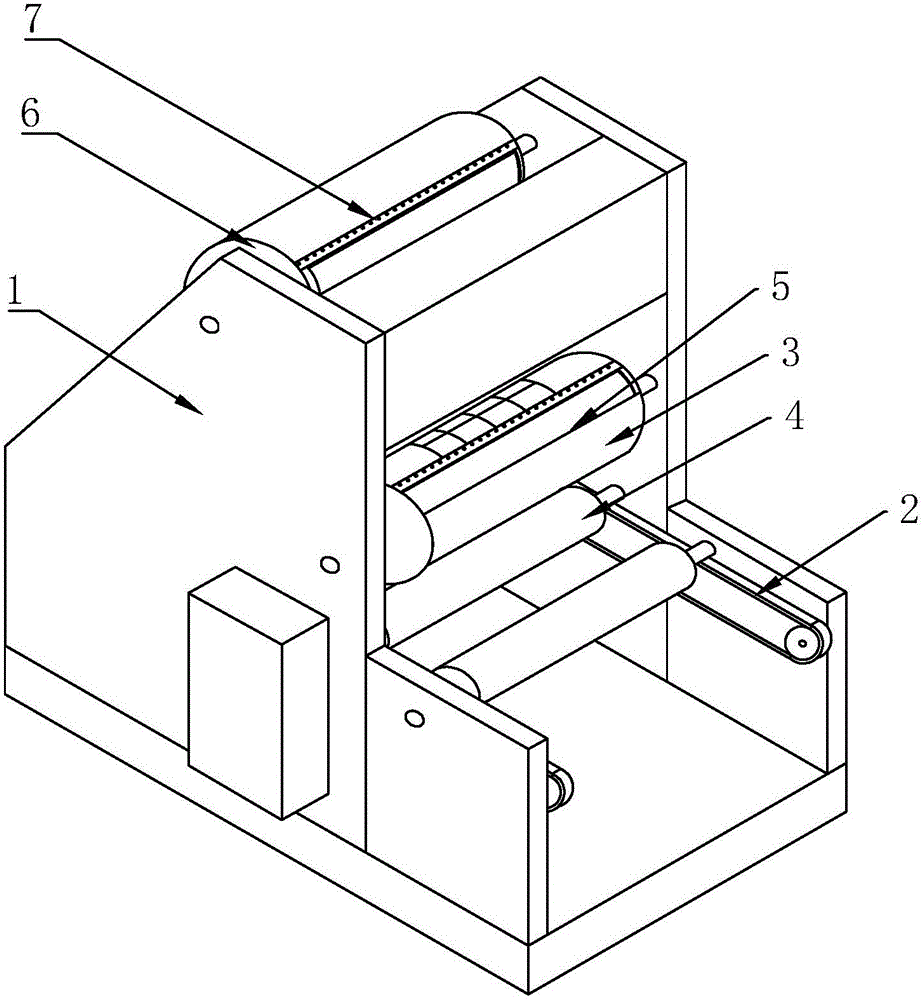

[0027] refer to Figure 1 to Figure 2 The present invention will be further described.

[0028] An embossed letterpress 5 includes a substrate made of high manganese steel, on which a printed layer corroded by photosensitive glue is arranged, and the thickness of the substrate is 50-80 silk meters.

[0029] By adopting the above technical scheme, the high manganese steel has a relatively high manganese content, can strongly reduce the impact human nature, and has strong tensile strength, and is not easy to be worn when using the embossed letterpress 5 printing product of the present invention Deformation, choose steel plate as the processing substrate, people can choose this kind of embossed letterpress 5 to use on the die-cutting machine, enhance the corrosion resistance of the die-cutting machine, or people choose this kind of embossed letterpress 5 to use on the printing machine, to print out high and low The uneven concave-convex embossing makes the printed pattern more d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com