Method for removing manganese from molten iron in top and bottom combined blown convertor

A top-bottom combined blowing and molten iron technology, which is applied in the field of demanganization of converter molten iron, can solve the problems of high manganese content and cannot meet the requirements of demanganization, and achieve the effect of high demanganization efficiency, low price and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

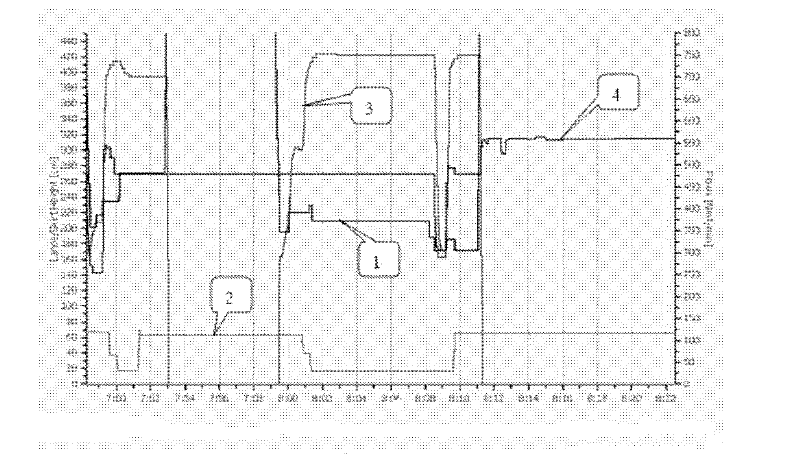

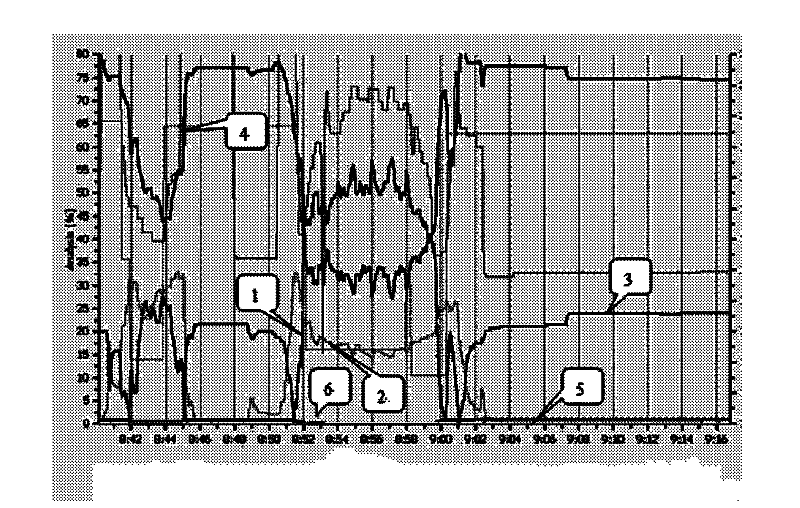

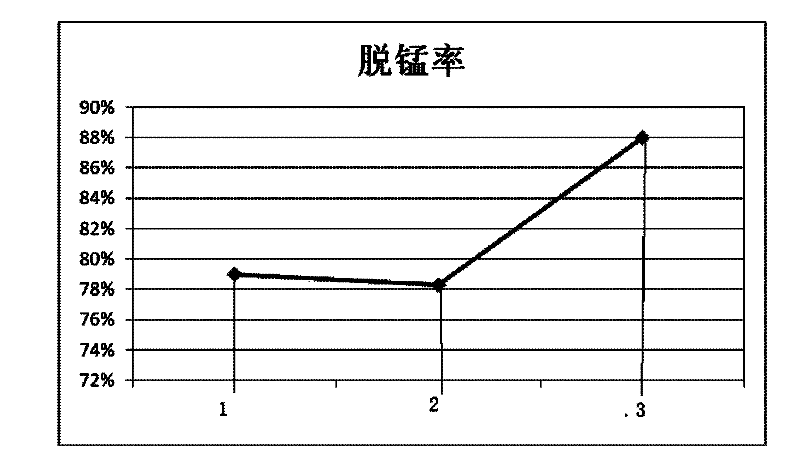

[0034] The experiment was carried out in a 210-ton top-bottom combined blowing converter. The amount of molten iron, steel scrap, and manganese removal agent added is shown in Table 1, and the composition of molten iron at different stages is shown in Table 2. First load light thin steel scrap and undemanganized hot metal, adjust the blowing oxygen lance position, start blowing, and then add the first batch of demanganization agent (lime, iron ore) into the converter through the hopper above the converter. The oxygen lance position and oxygen flow rate changes during blowing process are as follows: figure 1 As shown, observe the furnace gas analysis curve, when the CO curve starts to rise continuously (such as figure 2 As shown), lift the gun to dump the slag, and the amount of slag dumped is not less than 60% of the total slag. Lime, iron ore and fluorite) are added into the converter, and the oxygen lance position and oxygen flow change as follows: figure 1 shown. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com