304 stainless steel smelting method by AOD (argon oxygen decarburization) Converter

A 304 stainless steel, converter smelting technology, applied in the field of stainless steel smelting, can solve the problems of environmental pollution, high price, high price of manganese alloy, etc., and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

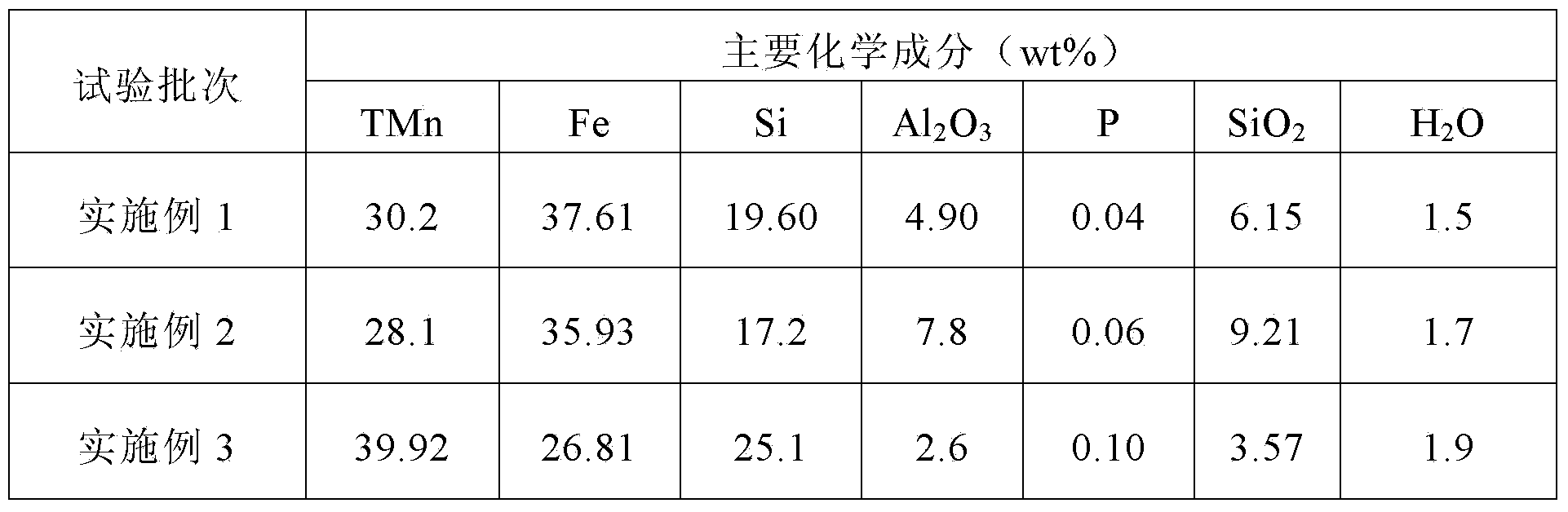

[0023] Using the method of the present invention, silimanganese ore balls are used in the process of smelting 304 stainless steel. The specific components are shown in Table 1, and the yield data are shown in Table 2.

[0024] Table 1 Composition of silimanganese balls in the test

[0025]

[0026] Remarks: The particle size of the mixed silimanganese ball is 42mm.

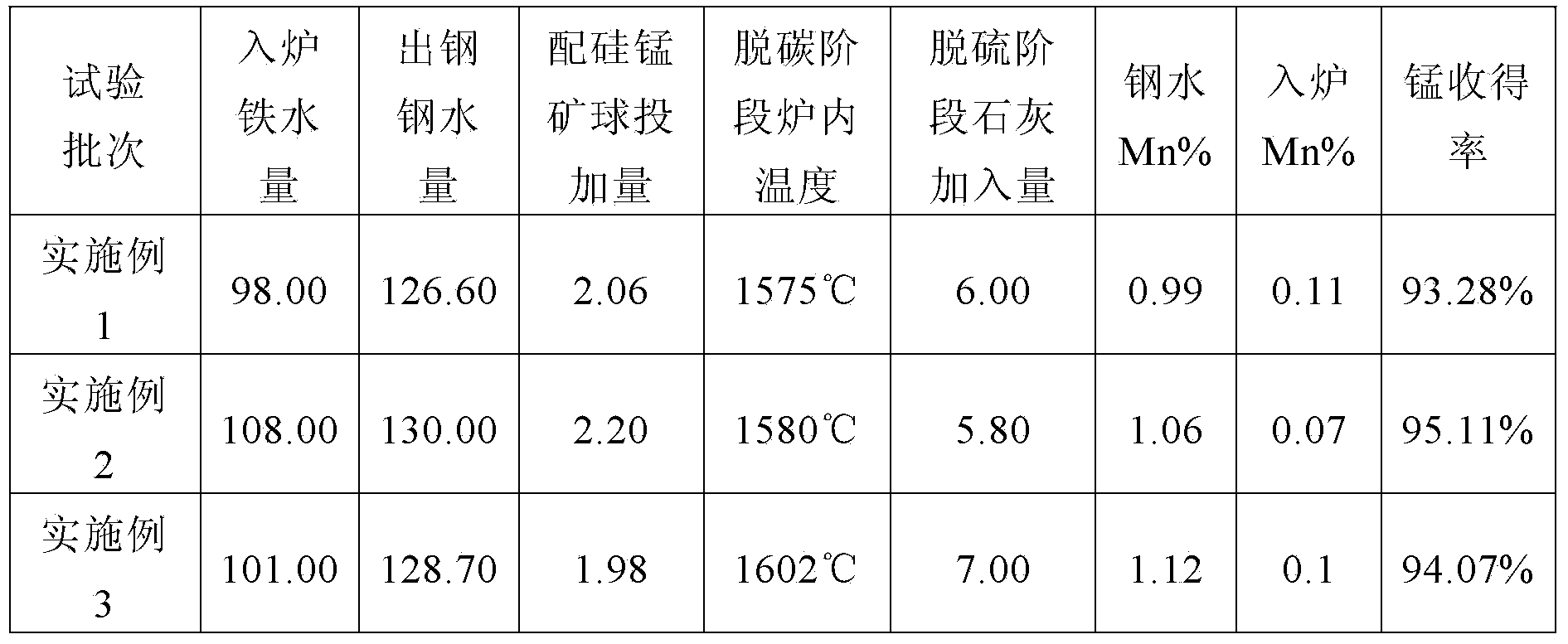

[0027] Table 2 Test yield data (unit: t)

[0028]

[0029] As shown in the above data, after the reduction phase begins, 2.06 tons, 2.20 tons, and 1.98 tons of silimanganese ore balls are added every 3 minutes for the third furnace of steel, and 6 tons, 5.8 tons, and 7 tons of lime are respectively added in the desulfurization phase. At the same time, in order to prevent the temperature in the furnace from being lowered after adding the charge in the reduction stage, the temperature was corrected in advance to 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com