Vibration arm connecting structure

A connection structure, vibrating arm technology, applied in non-rotational vibration suppression, threaded fasteners, screws, etc., can solve the problems of loosening, misalignment and wear, large noise and temperature rise, and deterioration of connection conditions, and achieve a degree of contact sticking. The effect of increasing the wear resistance and reducing the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

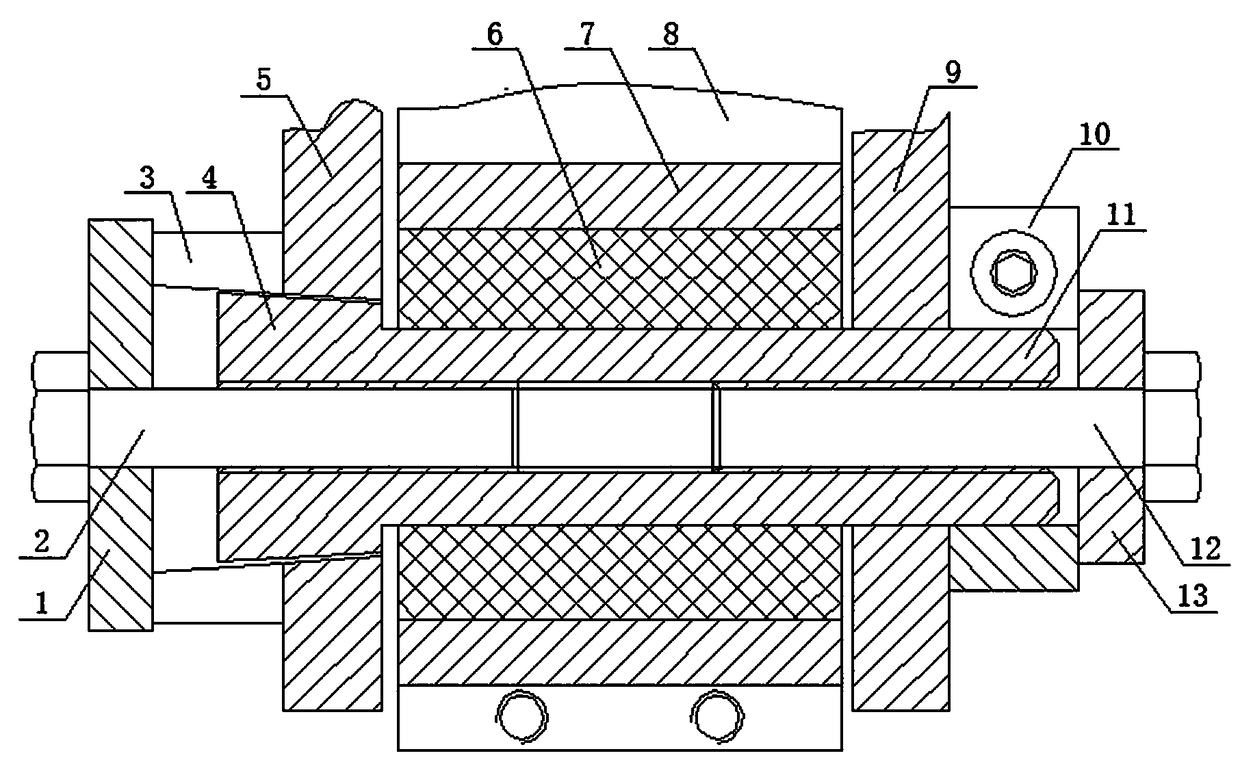

[0011] The present invention is further described below in conjunction with the accompanying drawings.

[0012] like figure 1 As shown, the present invention includes a vibrating arm 8 and a transmission support, the transmission support includes a left connecting ear 5 and a right connecting ear 9, and a trumpet-shaped through hole is provided on the left connecting ear 5. The inner diameter gradually decreases from left to right, the right connecting ear 9 is provided with a straight through hole coaxially arranged with the horn-shaped through hole, and between the left connecting ear 5 and the right connecting ear 9, there is a through-horn-shaped through hole and a straight through hole. The connection pin of the hole, the left end of the connection pin is the flared end 4, and the connection pin of the right part of the flared end 4 is the cylindrical shaft 11, and the diameter of the cylindrical shaft 11 is not larger than the flared end The outer diameter of the flared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com