Bolt device and special spanner

A bolt and wrench head technology, applied to bolts, wrenches, screws, etc., can solve problems such as difficult opening or locking, few force points on bolt caps, poor anti-theft performance of bolt devices, etc., to achieve strong anti-deformation and anti-slip capabilities, Not easy to wear and deform, good anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments.

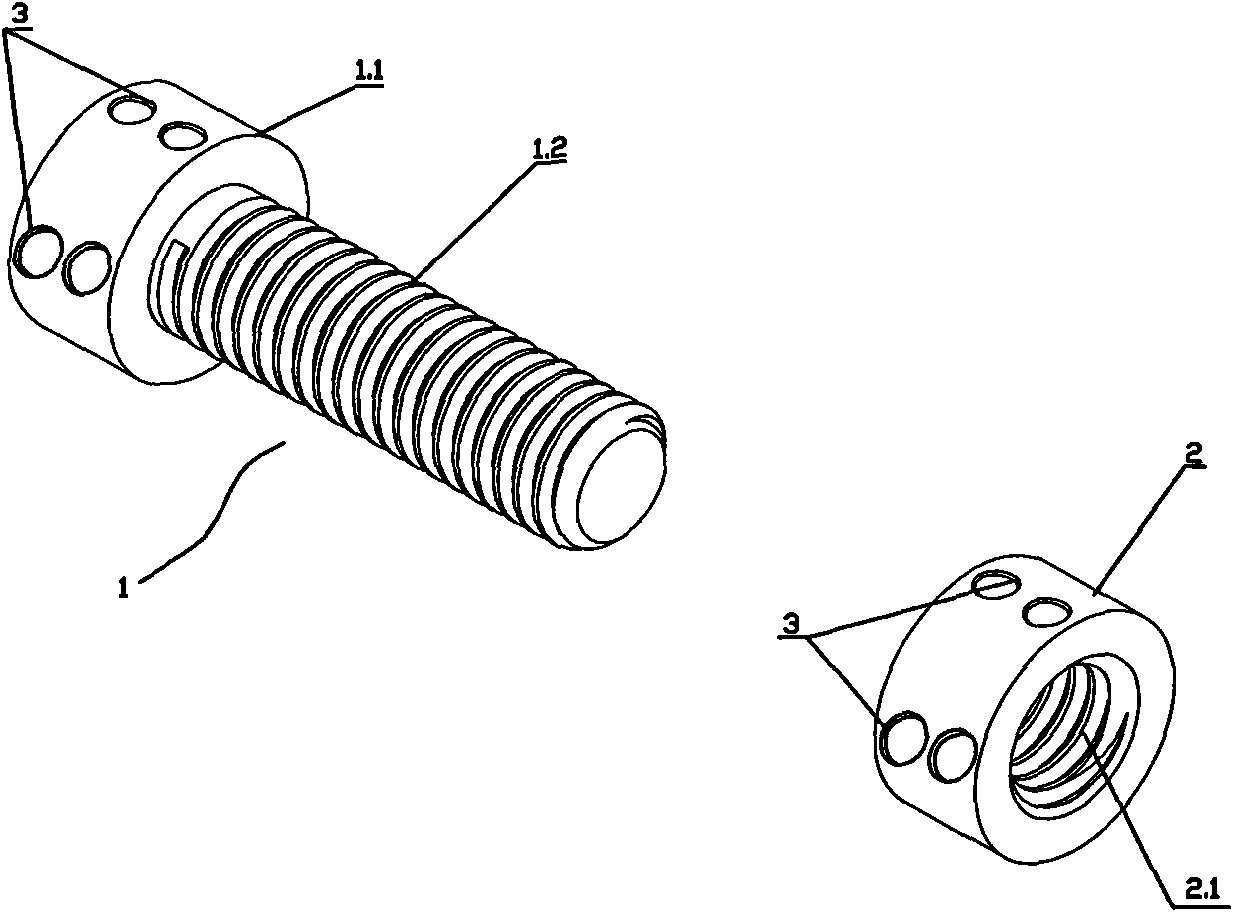

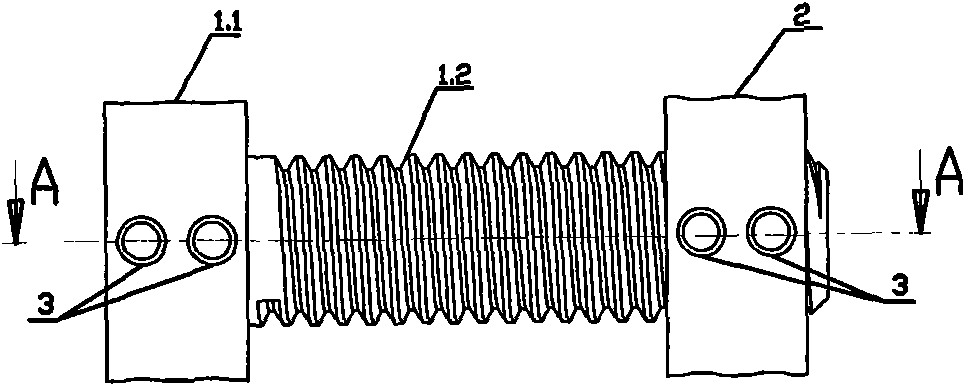

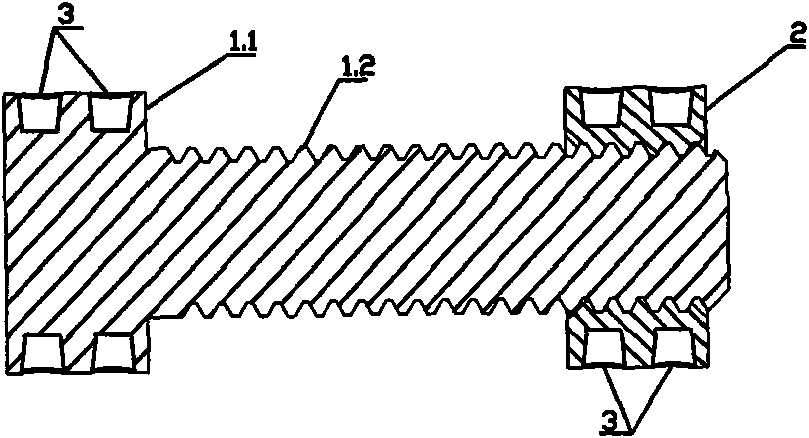

[0020] Such as figure 1 , figure 2 , image 3 As shown, the bolt device of the present invention includes a bolt 1 and a nut 2. The bolt 1 is composed of a bolt cap 1.1 and a screw 1.2, and the screw 1.2 is provided with a full thread.

[0021] The outer circumference of the bolt cap 1.1 is provided with four pairs of radial blind holes 3 distributed along the axial direction of the screw 1.2. The four pairs of radial blind holes 3 are evenly distributed along the outer circumference of the bolt cap 1.1, that is, two adjacent pairs The included angle between the radial blind holes 3 is 90 degrees.

[0022] The outer circumference of the nut 2 is also provided with four pairs of radial blind holes 3, each pair of radial blind holes 3 is distributed along the axial direction of the threaded hole 2.1, and the four pairs of radial blind holes 3 are along the nut 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com