Special inoculant for centrifugally casting thin-wall dry cylinder liner

A centrifugal casting and inoculant technology, applied in the new inoculant field, can solve the problems of increasing the production cost of cylinder liner casting, limiting the use of low-cost iron filings, etc., and achieves the effects of improving toughness, improving graphite morphology and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The chemical composition of the inoculant in this embodiment is Si: 450 grams, C: 200 grams, Ba: 35 grams, Ca: 8 grams, Al: 5 grams, Fe: 302 grams. When calculated in terms of mass percentage, Si is 45%, C is 20%, Ba is 3.5%, Ca is 0.8%, Al is 0.5%, and Fe is 30.2%.

[0014] When making the inoculant, the materials of the above components are crushed, mixed, granulated and other processes to make the inoculant. That is, put the pre-customized silicon-barium alloy particles, micro-sulfur high-precision crystal graphite particles and other materials into the WZL type gravity-free mixer in proportion. The mixing time is 3 to 5 minutes. After sampling and checking the ingredients, store them to prevent moisture. Just keep it as a spare.

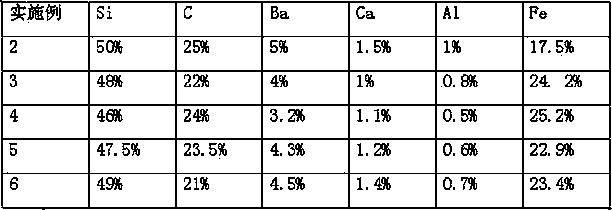

[0015] The following is a list of the chemical components of the inoculants with several components frequently used in the production obtained from the test. The measurement unit of the chemical components in the table is the mass percent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com