High-strength high-toughness wear-resistant ball and preparation process thereof

A preparation process and high toughness technology, applied in the field of wear-resistant balls, can solve the problems of low impact toughness, low hardness, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

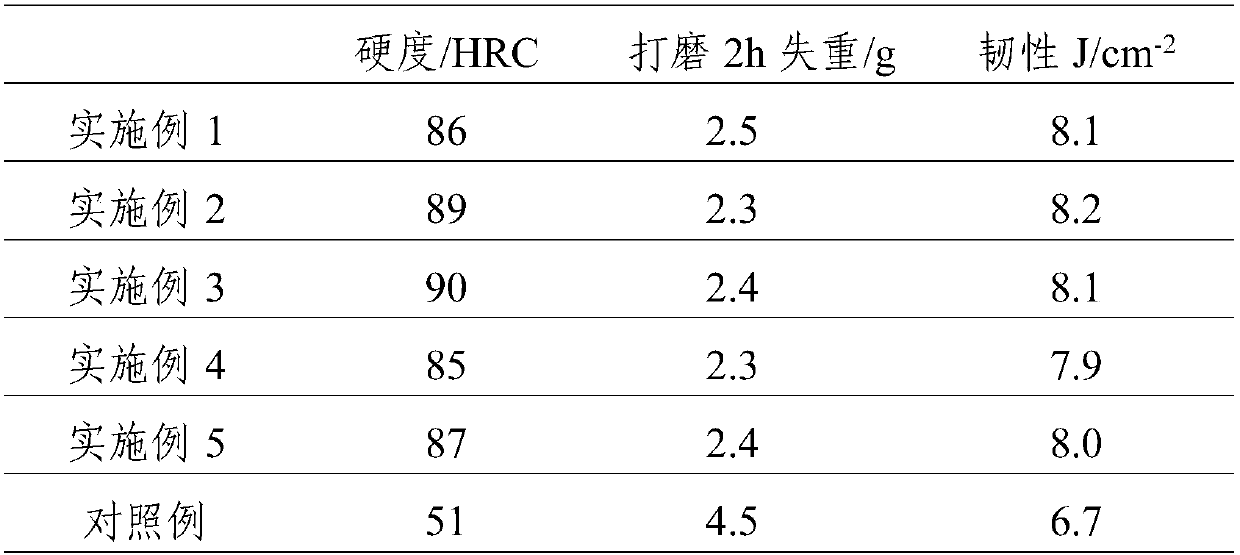

Embodiment 1

[0023] A high-strength and high-toughness wear-resistant ball, composed of the following elements: C: 1.5%, Si: 0.3%, Mn: 0.3%, Cr: 1.5%, W: 0.01%, Mo: 0.01%, P ≤0.05%, S≤0.05%, Sr: 0.05%, B: 0.05%, Zn: 0.1%, Mg: 0.02%, the balance is Fe;

[0024] The preparation process of the high-strength and high-toughness wear-resistant ball includes the following steps:

[0025] (1) Add pig iron, scrap steel, ferromanganese, ferrochrome, ferrotungsten, ferromolybdenum, ferro-strontium, ferro-zinc, ferro-magnesium, and recarburizer to the intermediate frequency induction furnace in sequence, heat to 1480°C, and smelt molten iron, then Carry out standing slag removal treatment;

[0026] (2) Add chromite sand powder to molten iron at 1480°C, stir evenly by ultrasonic, use wire feeding method to spheroidize, add SiFe and SiCa composite inoculant with 0.1% mass of molten iron, and incubate for a period of time;

[0027] (3) In the later stage of smelting, add a nodulizer to the nodulizer, c...

Embodiment 2

[0031] A high-strength and high-toughness wear-resistant ball, composed of the following elements: C: 2.5%, Si: 0.8%, Mn: 0.7%, Cr: 2.0%, W: 0.03%, Mo: 0.05%, P ≤0.05%, S≤0.05%, Sr: 0.15%, B: 0.1%, Zn: 0.4%, Mg: 0.04%, and the balance is Fe.

[0032] The preparation process of the high-strength and high-toughness wear-resistant ball includes the following steps:

[0033] (1) Add pig iron, steel scrap, ferromanganese, ferrochrome, ferrotungsten, ferromolybdenum, ferro-strontium, ferro-zinc, ferro-magnesium, and recarburizer to the medium-frequency induction furnace in sequence, heat to 1550°C, and smelt molten iron, then Carry out standing slag removal treatment;

[0034] (2) Add chromite sand powder to molten iron at 1530° C., stir evenly by ultrasonic, spheroidize by wire feeding method, add SiFe and SiCa composite inoculant with 0.1% mass of molten iron, and incubate for a period of time;

[0035] (3) In the later stage of smelting, add a nodulizer to the nodulizer, cover ...

Embodiment 3

[0039] A high-strength and high-toughness wear-resistant ball, composed of the following elements: C: 1.8%, Si: 0.5%, Mn: 0.4%, Cr: 1.6%, W: 0.01%, Mo: 0.02%, P ≤0.05%, S≤0.05%, Sr: 0.08%, B: 0.06%, Zn: 0.2%, Mg: 0.02%, and the balance is Fe.

[0040] The preparation process of the high-strength and high-toughness wear-resistant ball includes the following steps:

[0041](1) Add pig iron, scrap steel, ferromanganese, ferrochrome, ferrotungsten, ferromolybdenum, ferro-strontium, ferro-zinc, ferro-magnesium, and recarburizer into the medium-frequency induction furnace in sequence, heat to 1490°C, and smelt molten iron, then Carry out standing slag removal treatment;

[0042] (2) Add chromite sand powder to molten iron at 1490°C, stir evenly by ultrasonic, use wire feeding method to spheroidize, add SiFe and SiCa composite inoculant with 0.1% mass of molten iron, and incubate for a period of time;

[0043] (3) In the later stage of smelting, add a nodulizer to the nodulizer, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com