Rolling press device of composite tube

The technology of a rolling device and a composite pipe is applied in the field of rolling device of a composite pipe in the production of steel pipes, which can solve the problems of twisting and breaking of tie rods, reduction of production efficiency, increase of production cost, etc., so as to increase the expansion force and reduce the production cost. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

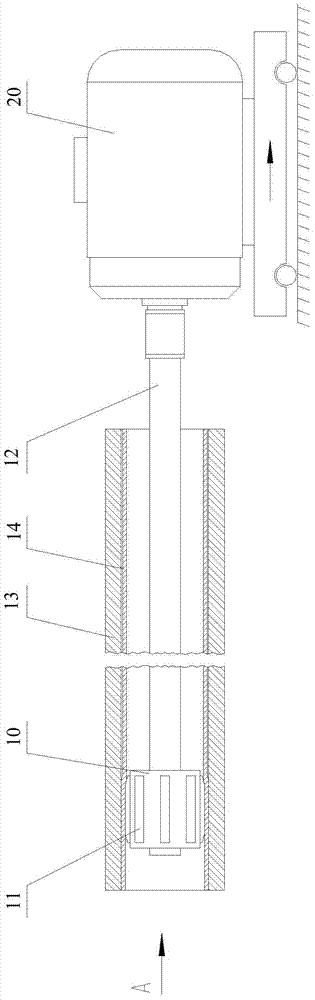

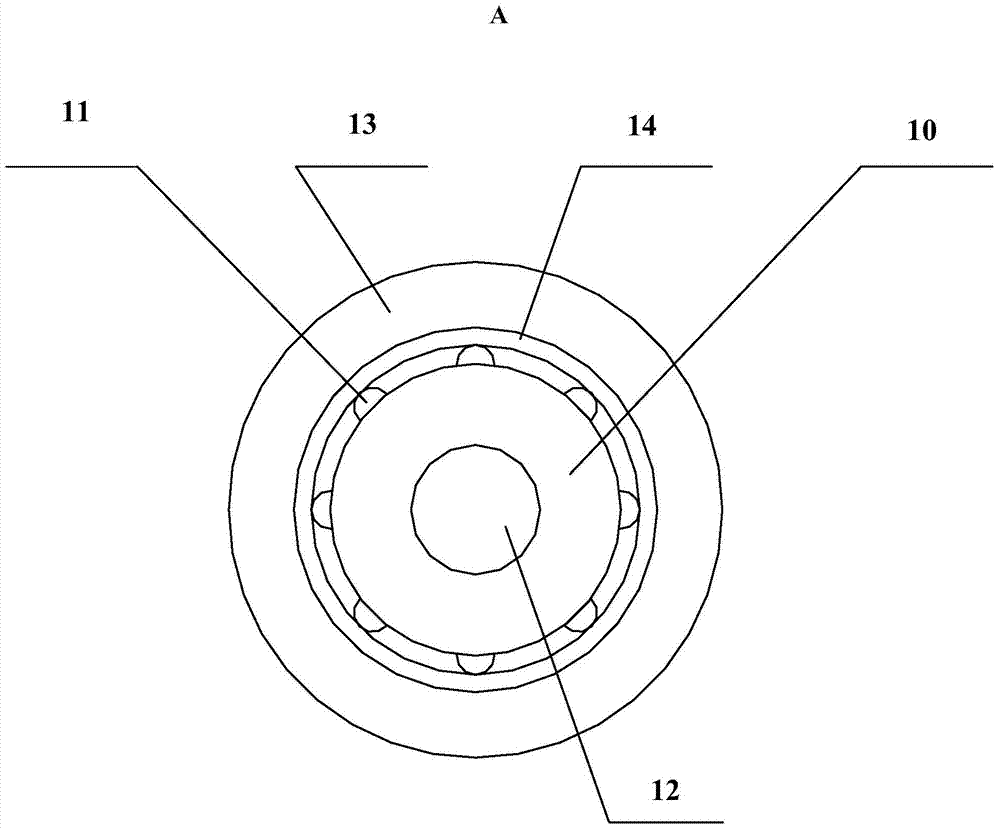

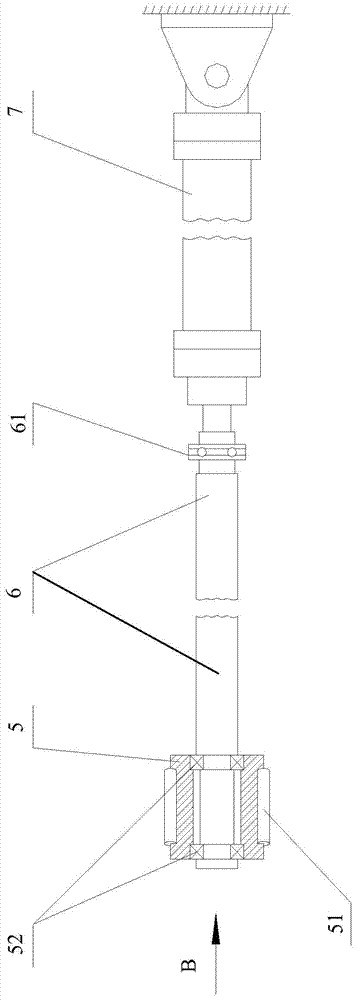

[0024] image 3 Shown is the structural representation of composite pipe rolling device of the present invention, Figure 4 shown as image 3 B direction view, such as image 3 as well as Figure 4 As shown, the composite pipe rolling device includes: a pull rod 6 , a roller 5 , a plurality of needle rollers 51 , bearings 52 , a rotary joint 61 and a hydraulic cylinder 7 .

[0025] Figure 5 Shown is the schematic diagram of the working state of the composite pipe rolling device of the present invention, Figure 6 shown as Figure 5 C direction view, such as Figure 3 to Figure 6 shown. The composite pipe is composed of the inner liner pipe 4 inserted into the mother pipe 3 . The roller 5 is cylindrical, and a bearing 52 is sheathed on its hollow inner side. The bearing 52 is mounted on the pull rod 6 so that the roller 5 can freely rotate relative to the circumference of the pull rod 6 . refer to Figure 5 , a plurality of needle rollers 51 are installed on the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com