point inoculation method

A technology of inoculation treatment and inoculant, applied in the field of spot inoculation treatment, can solve the problems of metallographic structure and graphite morphology not meeting the requirements, poor spheroidization, poor processing performance, etc., to improve metallographic structure and graphite morphology, improve Processability, effect of high spheroidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

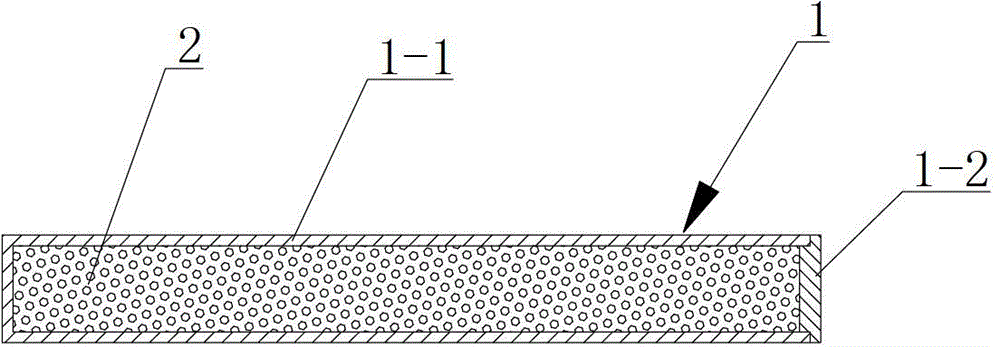

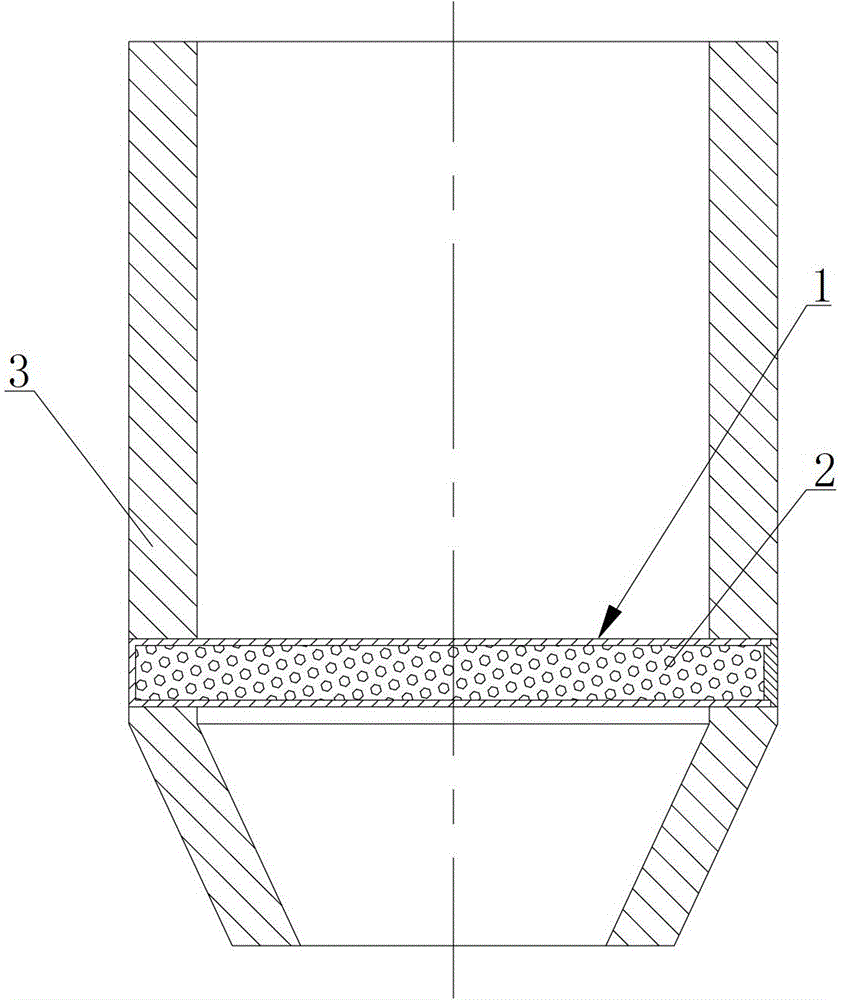

[0018] see figure 1 and 2 , a point inoculation treatment device, comprising a package body 1 filled with an inoculation treatment material 2 composed of an inoculant and a spheroidizer.

[0019] The shape of the above-mentioned package can adopt a cylindrical structure, an elliptical cylindrical structure, a square cylindrical structure, and the like. From the viewpoint of ease of molding or processing, the package is a cylindrical structure, which includes a cylindrical sleeve 1-1, one end of the sleeve is a closed end, and the other end is an open end. There are blocking parts 1-2.

[0020] A point inoculation treatment method, characterized in that, comprising the following steps:

[0021] Step 1: Mix the inoculant and the nodulizer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com