Alloy gray cast iron material for automobile brake disc, automobile brake disc and preparation method thereof

A technology of automobile braking and gray cast iron, which is applied in the field of alloy steel materials, can solve the problems that brake discs cannot meet the requirements of high-performance automobiles, achieve good thermal conductivity and wear resistance, and improve the effect of graphite morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

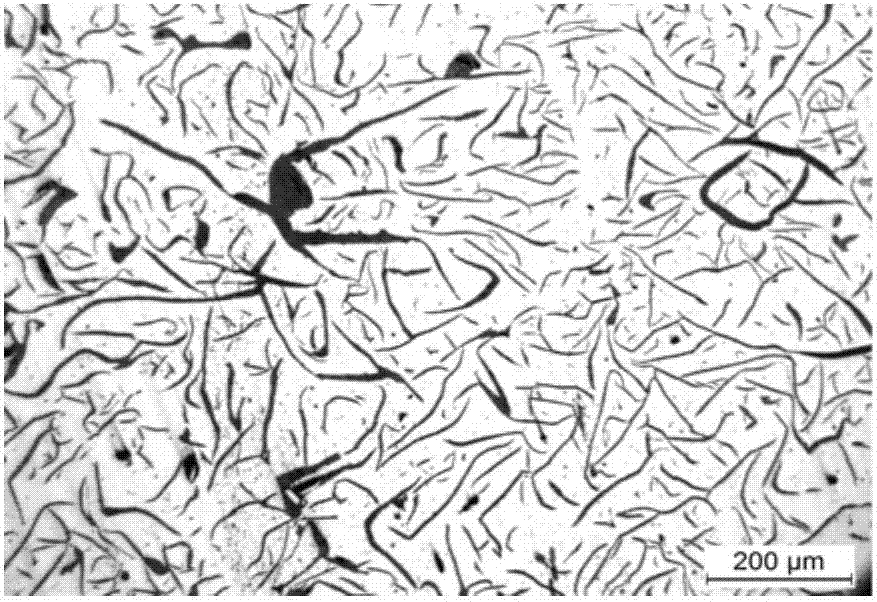

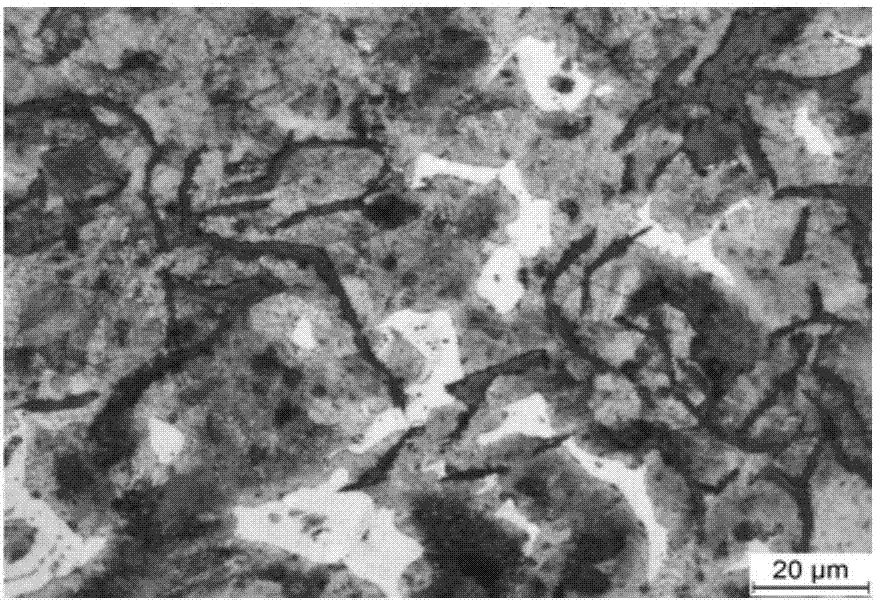

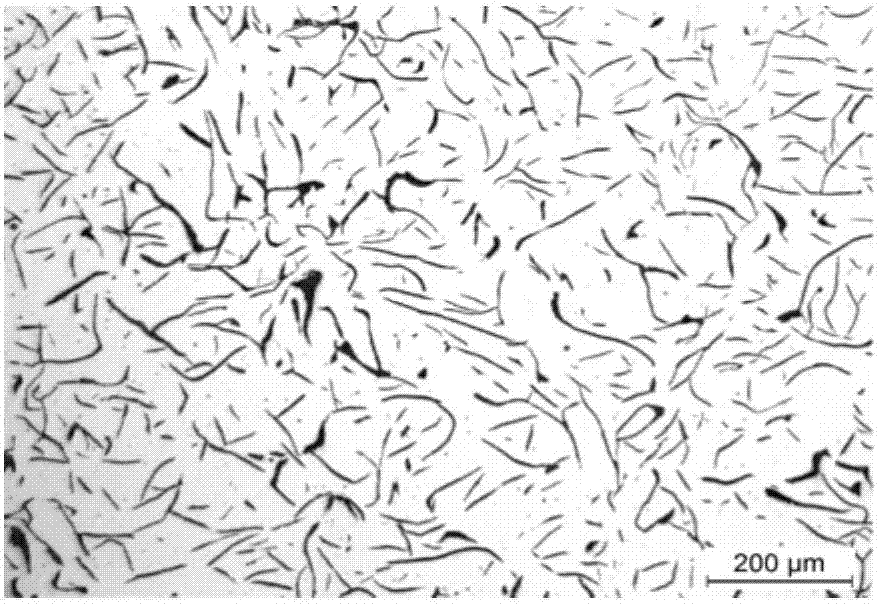

[0034] Due to the high carbon and phosphorus content of the existing brake discs, there are coarse C-type graphite and more phosphorus eutectic in the metallographic structure, resulting in its performance is far from reaching the requirements, so alloying design is required. The alloying elements often added to gray cast iron are chromium, vanadium, molybdenum, niobium, copper and so on. Chromium is a carbide forming element, 85% of which is dissolved in austenite during the solidification of molten iron, promotes the occurrence of metastable eutectic reaction, refines pearlite, and improves the strength of gray cast iron. Vanadium promotes the formation and refinement of pearlite and improves the strength and hardness of gray cast iron. After the casting is graphitized and annealed at high temperature, dispersed fine particulate precipitates will appear in the ferrite, and the strength and hardness will increase instead. . Molybdenum reduces the eutectic transition temperatu...

Embodiment 2

[0049] The weight percentages of the alloy gray cast iron materials are as follows: C content is 3.5% to 3.6%, Mn content is 0.5% to 0.6%, Cr content is 0.25%, Cu content is 0.7%, Nb content is 0.5%, and Si content is 1.8%, P content is ≤0.2%, S content is ≤0.12%, and the rest is iron.

Embodiment 3

[0051] The weight percentages of the alloy gray cast iron materials are as follows: C content is 3.5% to 3.6%, Mn content is 0.5% to 0.6%, Cr content is 0.35%, Cu content is 0.6%, Nb content is 0.5%, and Si content is 1.8%, P content is ≤0.2%, S content is ≤0.12%, and the rest is iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com