Heat treatment process for eliminating white-mouth defects of spheroidal graphite cast iron

A ductile iron and defect technology, which is applied in the field of heat treatment process to eliminate white defects of ductile iron, can solve the problems of affecting the service life of heat treatment equipment, the high cost of process repair, and the long process cycle affecting the delivery time. The effect of operability, short annealing cycle and high annealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

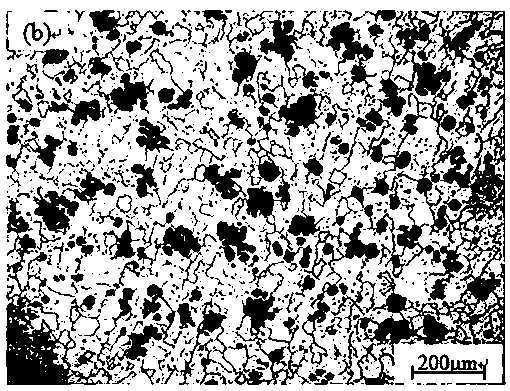

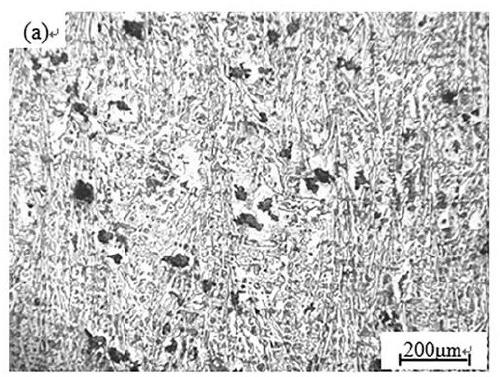

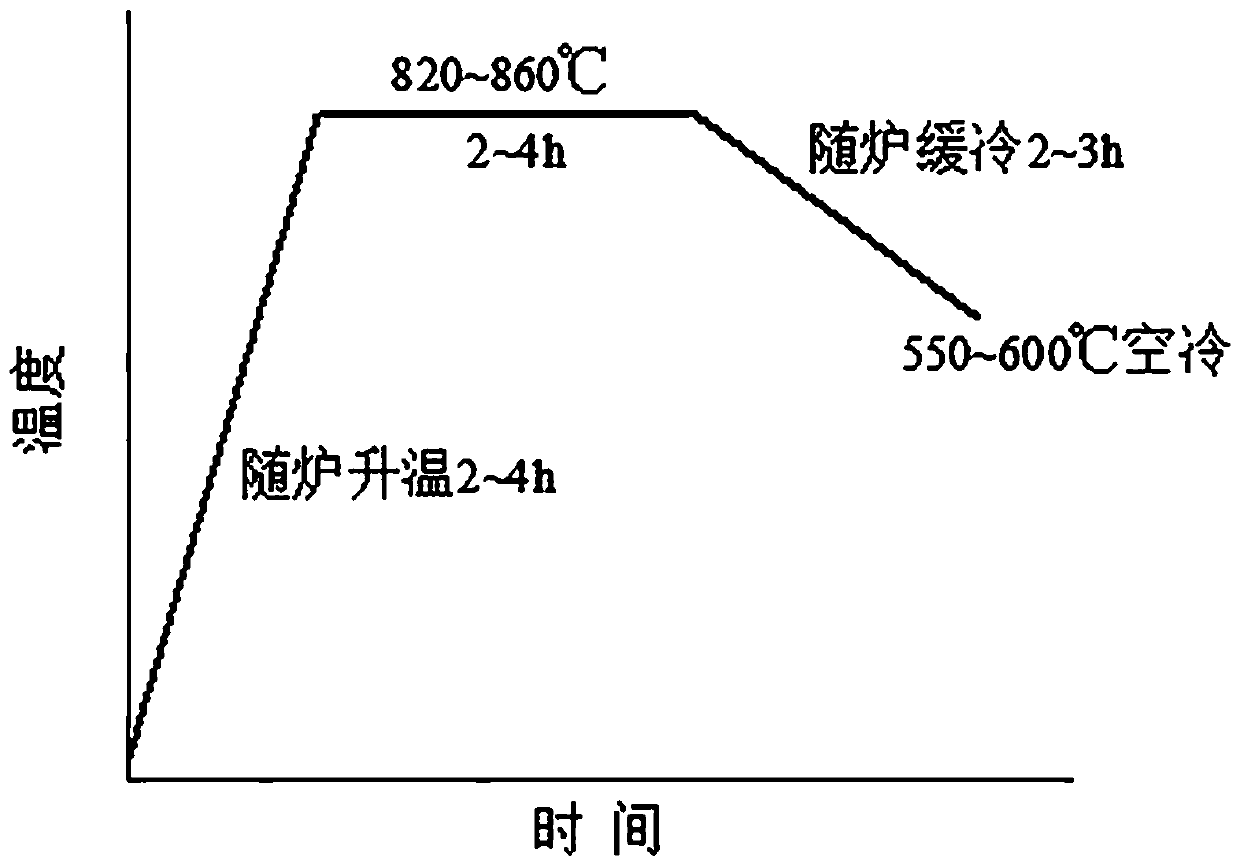

[0073] Example: Reference Figure 1~Figure 3 , a heat treatment process for eliminating the white defects of ductile iron, the model of the ductile iron is QT450-10, and a sampling inspection is required before heat treatment to confirm the morphology of the white microstructure, so as to determine different process parameters, including the following steps:

[0074] ①Heating up: heat up the ductile iron castings to be processed to the annealing temperature with the furnace;

[0075] ②Insulation: Keep the ductile iron castings at the annealing temperature for a period of time;

[0076] ③Slow cooling and cooling: make the ductile iron castings cool slowly with the furnace for a period of time;

[0077] ④Air cooling: After slow cooling, the ductile iron castings are taken out and air cooled.

[0078] Taking QT450-10 castings with white mouth defects (the wall thickness at the white mouth defects is about 10mm) as the process implementation object, Table 1 shows the parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com