Special steel for rolling roller blank and preparation method thereof

A roll and billet rolling technology, applied in the field of metallurgy, can solve problems such as poor material hardness, and achieve the effects of uniform and qualified annealing structure, low annealing temperature, and good heat treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

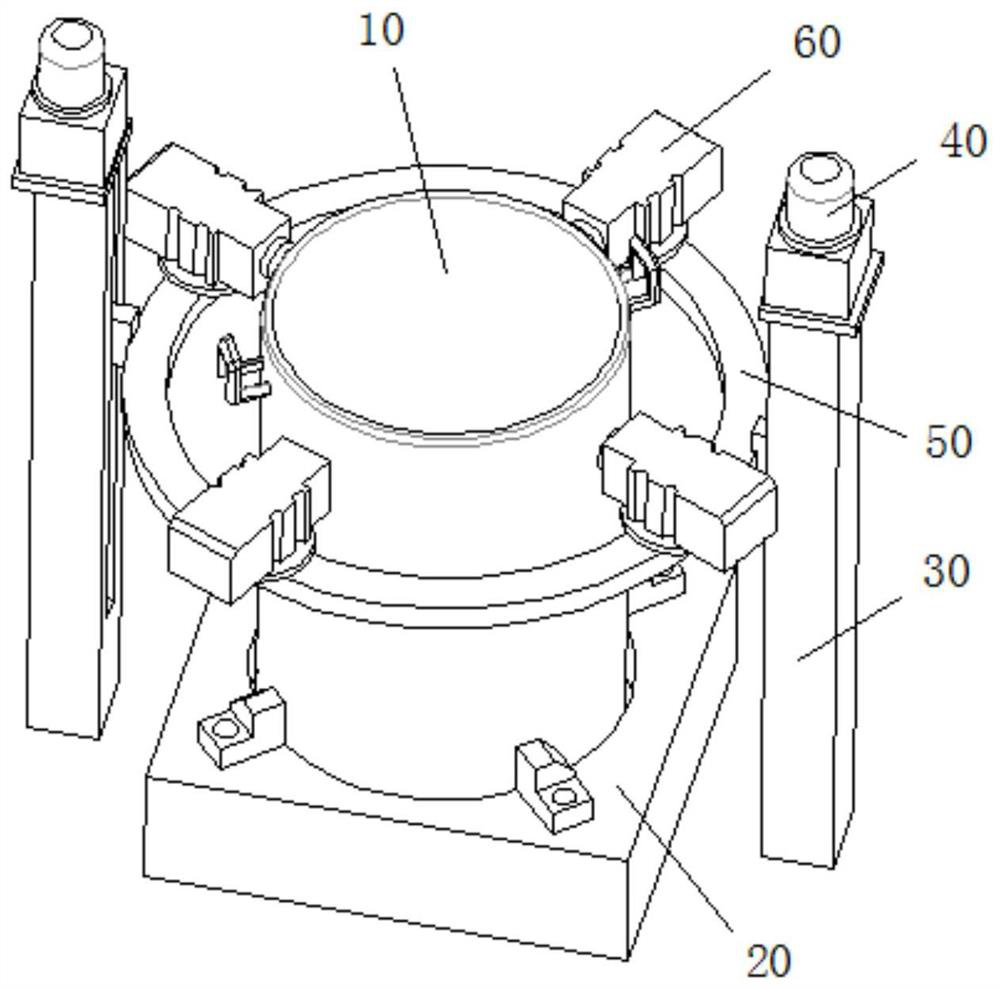

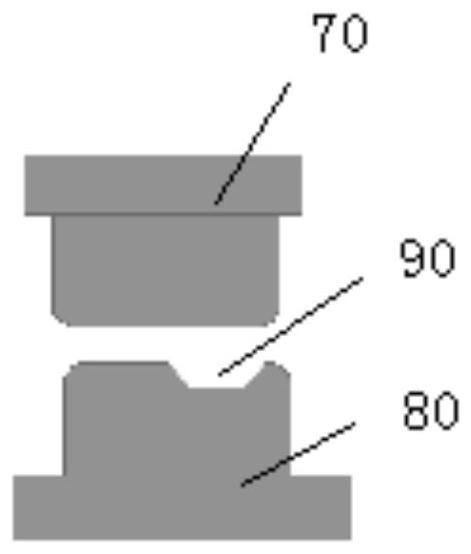

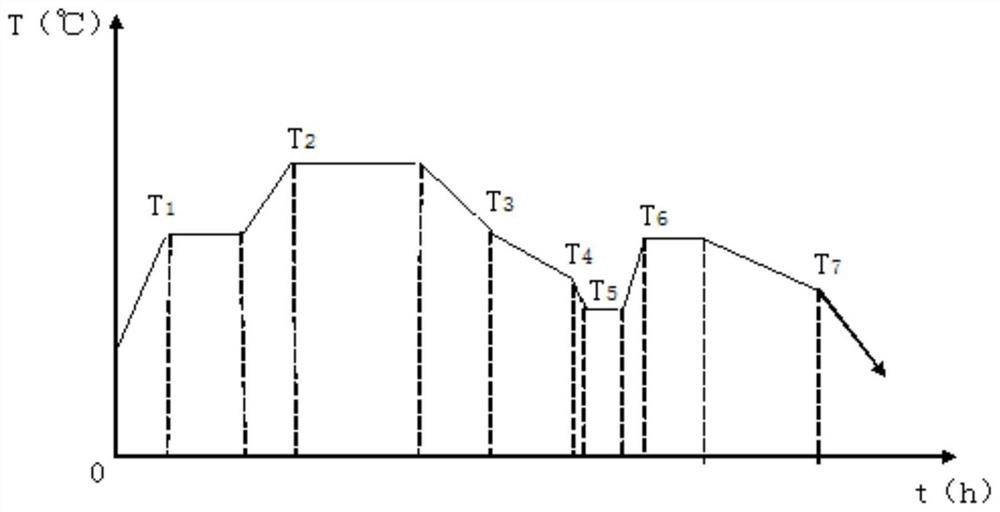

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0034] This embodiment relates to a special steel for rolling roll blanks. The special steel includes the following components in terms of mass percentage: C: 1.5%-1.60%, Si: 0.1-0.5%, Mn: 0.6%-0.7% , Cr: 12.0%-13.5%, Mo: 0.5-1.5%, W: ≤0.2%, V: 1.0-1.3%, S: 0.01-0.05%, N: 0.01%-0.05%, O: ≤0.005%, RE: 0.105-0.15%, the balance is iron and impurities.

[0035] Wherein, the above-mentioned component RE specifically includes the following elements in terms of mass percentage: lanthanum element: 40%, cerium element: 35%, rare earth magnesium alloy element: 25%. The rare earth magnesium alloy element is yttrium-based rare earth magnesium alloy.

[0036] During specific preparation, the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com