One tenth hardness quenching and tempering and annealing technique for chilled steel strip

An annealing process and steel strip technology, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems that the plastic deformation cannot be met, and the cold-rolled steel strip cannot meet the high-strength technical requirements, so as to increase the elongation and reduce the processing cost. The effect of low and short annealing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Variety 08AL, specifications: thickness 0.35-0.70mm, width 430-610mm, technological process; a section of heating steel strip is heated from normal temperature to 450°C, and the heating rate is 3°C / min; a section of holding temperature is 450°C, holding time 1.5 hours, purge time 1.5 hours, purge flow 7m 3 / h; the second-stage heating steel strip continues to be heated to 500°C, the heating rate is 0.4°C / min, the second-stage holding temperature is 500°C, the holding time is 5 hours, and the purge flow rate is 8m 3 / h, and the purging time is 3 hours; the furnace is sprayed with water to cool to a temperature of 300°C, and the furnace is air-cooled to 100°C, and then it is discharged from the furnace.

Embodiment 2

[0035] Example 2: Variety Q195, specifications: thickness 0.71-1.40mm, width 610-720mm, technological process: a section of heating steel strip is heated from normal temperature to 455°C, and the heating rate is 3°C / min; a section of holding temperature is 455°C, holding time 1.8 hours, purge time 1.8 hours, purge flow 7m 3 / h; the second-stage heating steel strip continues to be heated to 505°C, the heating rate is 0.45°C / min, the second-stage holding temperature is 505°C, the holding time is 5.5 hours, and the purge flow rate is 8m 3 / h, the purging time is 3 hours; the furnace is sprayed with water to cool to a temperature of 310°C, and the furnace is air-cooled to 110°C before being discharged from the furnace.

Embodiment 3

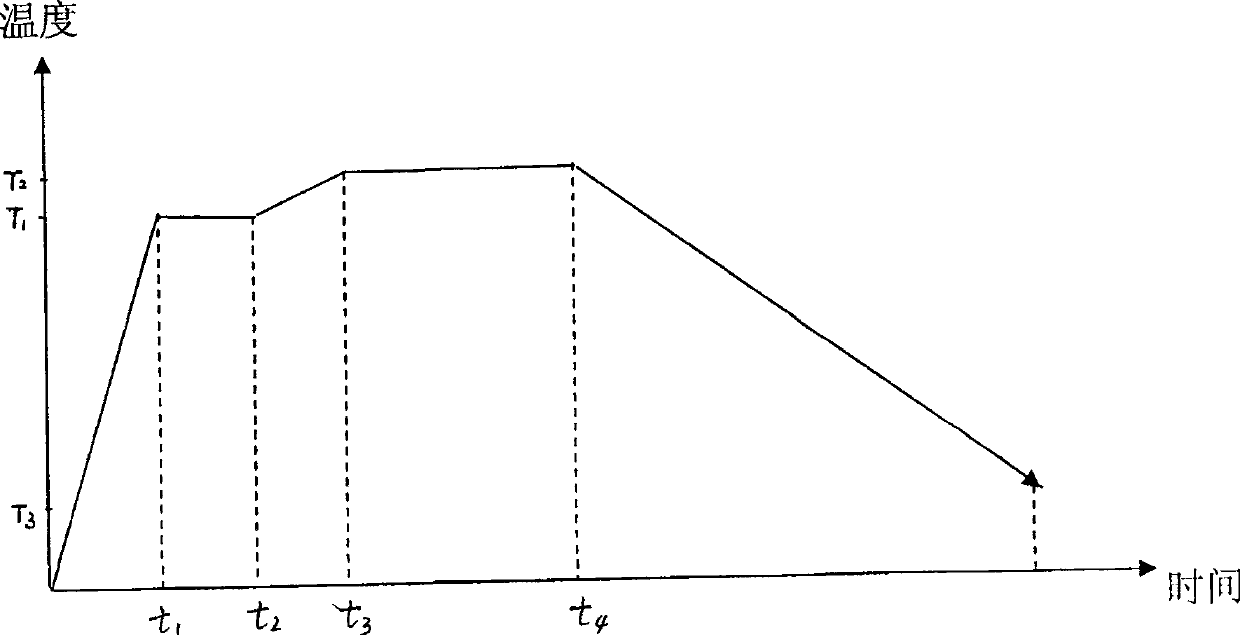

[0036] Embodiment 3: variety Q195L, specifications: thickness 1.41-2.00 mm, width 720-830 mm. see figure 1 , process: a period of heating time is t 1 , the steel strip is heated from room temperature to temperature T 1 is 460°C, and the heating rate is 3°C / min; 2 -t 1 ) temperature T 1 460°C, holding time 2 hours, purge time 2 hours, purge flow 7m 3 / h; second stage temperature rise (t 3 -t 2 ) The steel strip continues to be heated to T 2 is 510°C, the heating rate is 0.5°C / min, the second stage (t 4 -t 3 ) holding temperature T 2 The temperature is 510℃, the holding time is 6 hours, and the purge flow rate is 8m 3 / h, the purging time is 3 hours; the furnace is sprayed with water to cool to a temperature of 305°C, and the furnace is air-cooled to a temperature of T 3 105°C, out of the oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recrystallization temperature | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com