Silicon carbide reinforced synthetic vermicular graphite cast iron material and preparation method thereof

A technology of vermicular graphite cast iron and silicon carbide, which is applied in the field of silicon carbide reinforced synthetic vermicular graphite iron material and its preparation, can solve the problems of being easily affected by the international environment, low product yield, controlled by people, etc., and has a wide range of applications. , The effect of improving economic efficiency and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

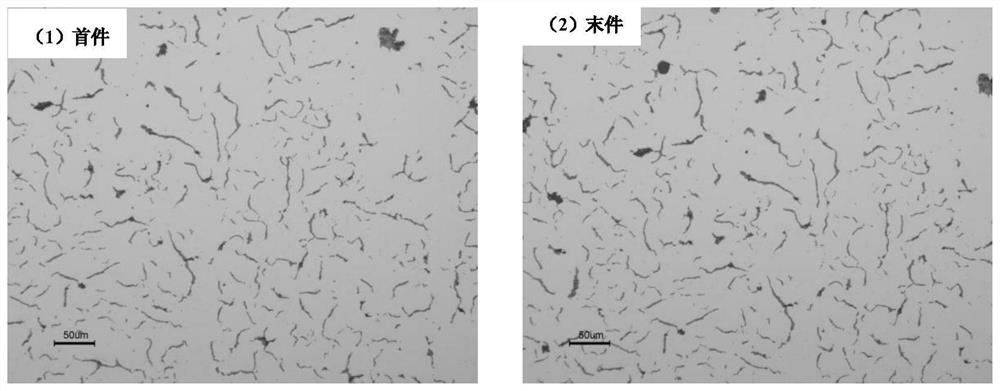

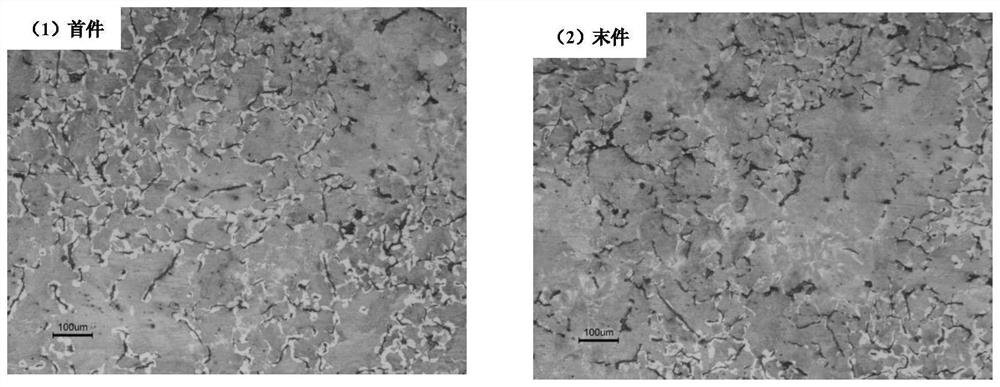

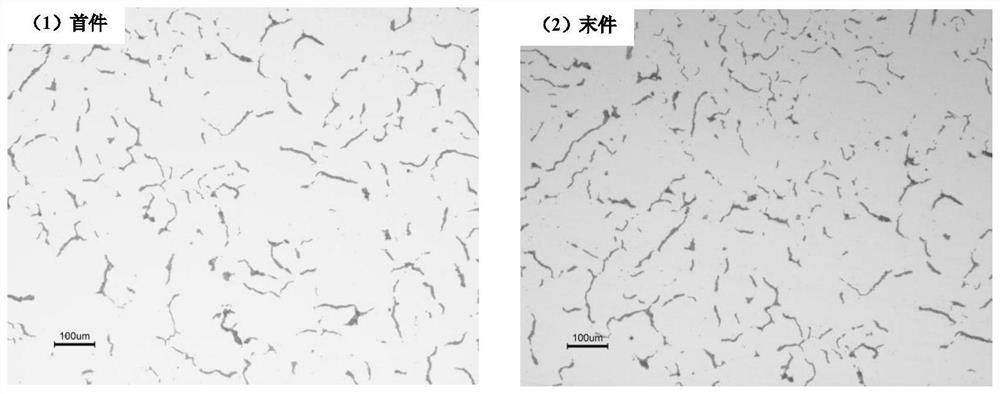

[0027] Example 1: A silicon carbide reinforced synthetic vermicular graphite cast iron material, ingredients calculation: the mass percentage of each element is: C: 3.8%, Si: 1.6%, Mn: 0.015%, P<0.03%, S<0.03%, Ti : 0.03%, Cu: 1.0%, Mg: 0.016%, and the balance is Fe and unavoidable impurities.

[0028] The specific preparation process is:

[0029] (1) Smelting and pouring: Add 45 parts by mass of returned material and 43 parts of 10 scrap steel, 2 parts by mass of silicon carbide (2 / 3 of the required amount of silicon carbide) and graphite with a particle size of 5-10mm and 10 parts by mass. The carbon agent is added to the medium frequency induction furnace for melting. The order of adding the charge is: return charge—the mixture of recarburizer and silicon carbide—scrap steel—other ferroalloys. The recarburizer and silicon carbide are placed in the middle of the furnace body. After melting, measure whether the content of C and Si elements in the molten iron meets the requir...

Embodiment 2

[0034] Example 2: A silicon carbide reinforced synthetic vermicular graphite cast iron material, ingredients calculation: the mass percentage of each element is: C: 3.6%, Si: 2.0%, Mn: 0.01%, P<0.03%, S<0.03%, Ti : 0.05%, Cu: 0.8%, Mg: 0.020%, the balance is Fe and unavoidable impurities.

[0035] The specific preparation process is:

[0036] (1) Smelting and pouring: add 50 parts by mass of returned charge, 45 parts of 45 steel scrap, 6 parts by mass of silicon carbide (2 / 3 of the required amount of silicon carbide), and 5-10 mm in particle size, 10 parts of graphite The carbon agent is added to the medium frequency induction furnace for melting. The order of adding the charge is: return charge—recarburizer and silicon carbide—scrap steel—other ferroalloys, recarburizer and silicon carbide are placed in the middle of the furnace body, and after melting, measure whether the content of C and Si elements in the molten iron meets the design requirements , fine-tuning by adding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com