Vermicular graphite cast iron and preparation process and application thereof

A technology of graphite cast iron and preparation process, applied in mechanical equipment, rotary piston machinery, machines/engines, etc., can solve problems such as mechanical strength fracture of scrolls, avoid increased hardness, improve mechanical properties, and low elongation requirements Effect

Active Publication Date: 2019-04-09

苏州勤美达精密机械有限公司

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The working temperature of the refrigeration compressor is in the working range of -10°C to 60°C; the heat pump compressor is mainly used for heating and heating in winter in the north, and the working temperature is in the working range of -30°C to 90°C; the heat pump compressor The scroll disk, the core part, needs to withstand a working temperature difference as high as 120°C, but the scroll disk used for refrigeration compressors on the market can only withstand a working temperature difference of 70°C

In the working environment with high temperature difference and harsh working conditions, the scroll made of ordinary gray cast iron may have the risk of fracture due to insufficient mechanical strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0037] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

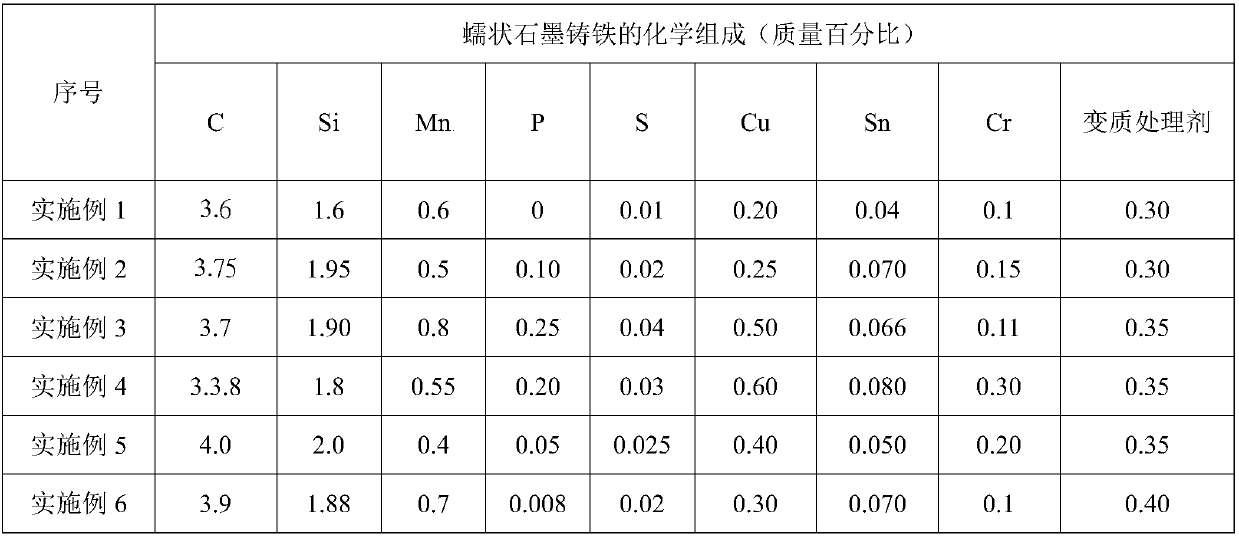

[0038] Examples 1-6 are the elemental components of each test material of the present invention.

[0039]

[0040] Table 1 Example 1~6 chemical composition

[0041]

[0042] The chemical composition of deterioration treatment agent in table 2 embodiment 1~6

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

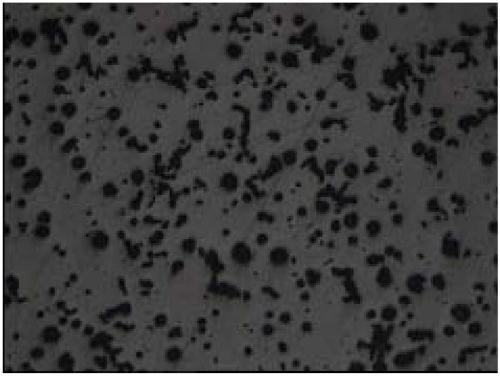

The invention discloses vermicular graphite cast iron and preparation process and application thereof. By mass percentage, 3.6%-4.0% of C, 1.6%-2.0% of Si, 0.4%-0.8% of Mn, 0%-025% of P, 0.01%-0.04% of S, 0.20-0.6% of Cu, 0.04%-0.08% of Sn, 0.10%-0.3% of Cr, and the balance Fe and accompanying impurities are included. In the production process, 0.30%-0.40% of a modification agent is adopted in theproduction process to control the vermicularity of the graphite form to be 20%-60%, the mechanical performance of a material is greatly improved, the strength of extension is larger than or equal to450 N / mm<2>, the yielding strength is larger than or equal to 315 N / mm<2>, the elongation at break is smaller than or equal to 3%, a hardness range is HB200-250, the endurance service life reaches 2600 h according to a test, and the vermicular graphite cast iron can be applied to a compressor core part vortex disk high in mechanical strength requirement.

Description

technical field [0001] The invention relates to a graphite cast iron, in particular to a vermicular graphite cast iron and its preparation process and application; it belongs to the technical field of graphite cast iron. Background technique [0002] The formation process of graphite in cast iron is called graphitization process, and the basic process of cast iron structure formation is the formation process of graphite in cast iron. The type and size of graphite in gray cast iron depends on the branching and growth rate of graphite in the eutectic group. When the eutectic group stops growing, the growth of graphite also stops. Because gray cast iron has good casting performance, vibration damping performance, wear resistance, cutting performance and low notch sensitivity, it has been widely used in the field of casting technology. [0003] According to the morphology of graphite, gray cast iron can be divided into: ordinary gray cast iron, nodular cast iron, malleable cast...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C33/10C22C37/06C22C37/10F04C18/02

CPCC21D2211/005C21D2211/009C22C33/10C22C37/06C22C37/10F04C18/02

Inventor 陈智颂

Owner 苏州勤美达精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com