Heat Treatment Process and Application of Ductile Iron Piston Castings

A technology of ductile iron and piston, which is applied in the field of heat treatment of ductile iron castings, can solve the problems of quenching cracks, reduce the wear resistance of pistons, and have a large tendency to deform and crack, so as to prevent casting deformation, reduce thermal stress, and refine The effect of pearlite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

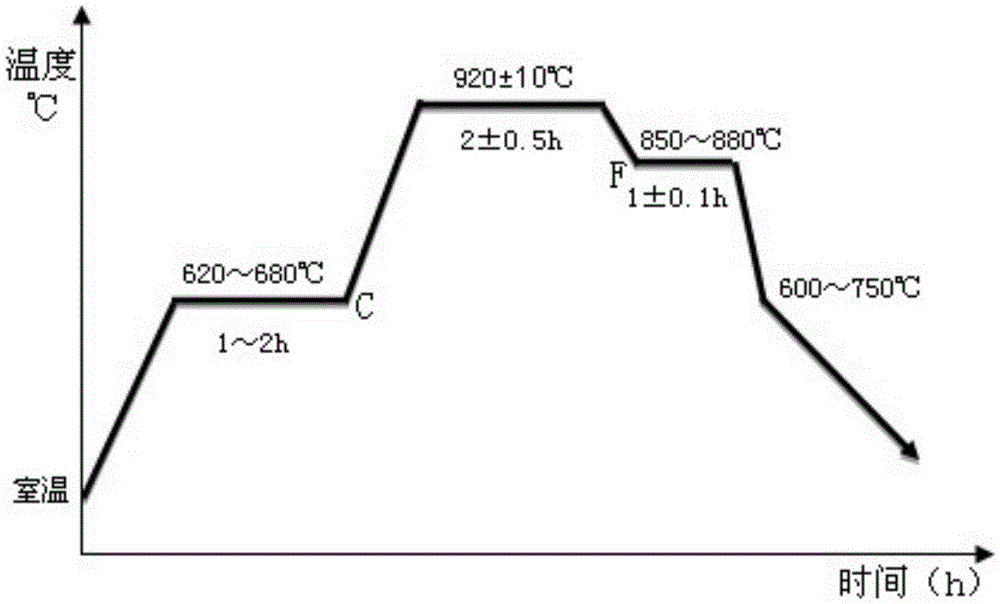

[0033] See figure 1 Shown, the heat treatment process of ductile iron piston casting of the present invention, according to the following steps,

[0034] a. Put the ductile iron piston casting at room temperature into the electric furnace, heat it to 620-680°C, keep it warm for 1-2 hours, and preheat the ductile iron piston casting to make the temperature of the ductile iron piston casting uniform. , The ductile iron piston castings with uneven wall thickness are preheated to effectively reduce the thermal stress of the ductile iron piston castings and prevent the deformation of the piston castings. The present invention is shown in Table 1 to the concrete embodiment of ductile iron piston casting preheating temperature and time.

[0035] Table 1

[0036] project

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

temperature(℃)

630

640

650

660

665

670

675

680

time (h) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com