Manufacturing method for hydraulic castings produced through non-alloyed high-strength gray cast iron

A non-alloyed, high-strength technology, applied in the field of materials, can solve problems such as low comprehensive performance, high carbon content in furnace charge, and unspecified cooling time of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

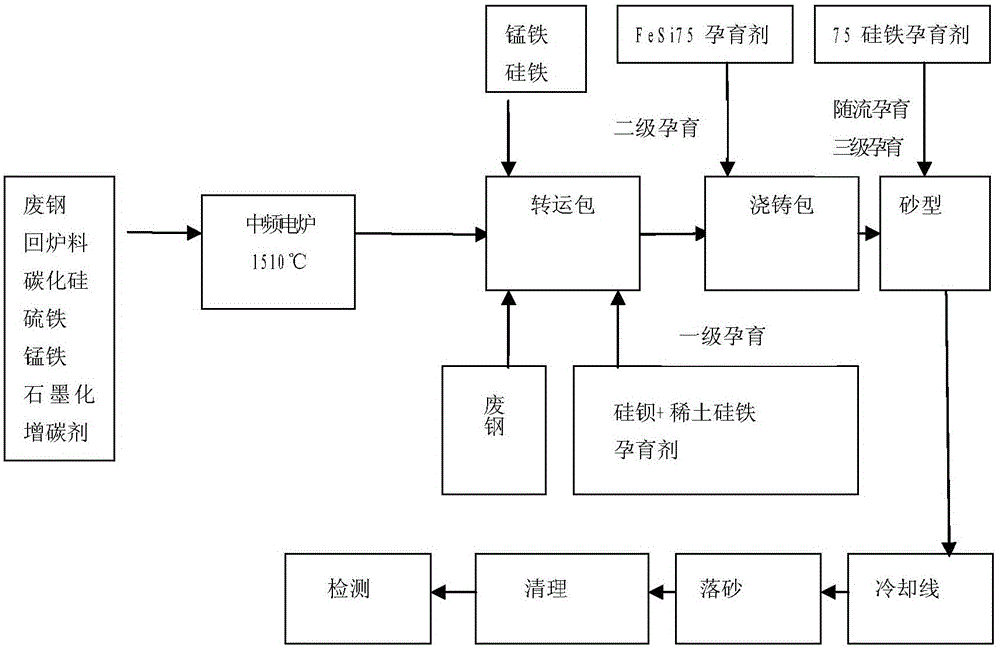

Method used

Image

Examples

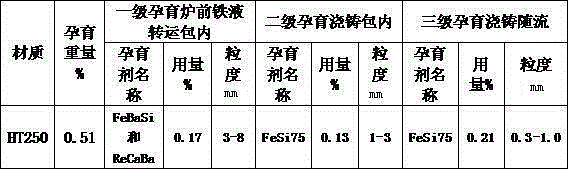

Embodiment 1

[0029] Step 1. Determine that the material HT250 is the BZZ full hydraulic steering gear valve body, the required chemical composition and the relationship between the elements: C: 3.15-3.25%, Si: 2.10-2.20%, Mn: 0.80-0.90%, P <0.1%, S: 0.08~0.12%, CE: 3.86~3.94%, the rest is Fe; and, ω(Si) / ω(C): 0.68~0.69, the difference between Si-Mn is 1.3, inoculated silicon and The ratio of total silicon: ω(Si pregnant) / ω(Si final) is 0.2~0.3.

[0030] Step 2: Smelting in an intermediate frequency induction furnace: 80% carbon scrap steel and 20% recycled material are used as the furnace charge; among them, the carbon scrap steel contains the following chemical components in mass percentages: C: 0.2%, S: 0.2%, Mn: 0.4% , the returned material is the same grade as the casting. Place the returned material on the bottom of the furnace, and place the scrap steel on the returned material;

[0031] When one-third of the charge is melted, add a graphitized recarburizer whose weight is scrap st...

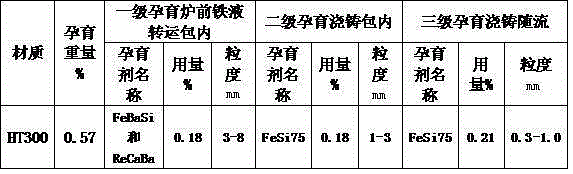

Embodiment 2

[0050] Step 1. Determine the BM series cycloidal hydraulic motor valve body made of HT300, the required chemical composition and the relationship between the elements: C: 3.10-3.20%, Si: 2.10-2.20%, Mn: 0.85-0.95% , P<0.1%, S: 0.08~0.12%, CE: 3.86~3.94%, the rest is Fe; the ω(Si) / ω(C): 0.68~0.69, the difference between Si-Mn is 1.25, and the incubating The ratio of silicon to total silicon: ω (Si pregnant) / ω (Si final) is 0.25 to 0.35.

[0051] Step 2: Smelting in an intermediate frequency induction furnace: 80% carbon scrap steel and 20% recycled material are used as the furnace charge; among them, the carbon scrap steel contains the following chemical components in mass percentages: C: 0.2%, S: 0.2%, Mn: 0.4% , the returned material is the same grade as the casting. Place the returned material on the bottom of the furnace, and place the scrap steel on the returned material;

[0052] When one-third of the charge is melted, a graphitized recarburizer whose weight is 2t*2.74%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com