Inoculant for increasing strength of gray cast iron, preparation method and use method thereof

A technology of inoculant and gray cast iron, which is applied in the field of inoculants for increasing the strength of gray cast iron and its preparation, can solve the problems of large residual stress, shrinkage cavity, increased shrinkage tendency, poor fluidity, etc., and achieve the effect of solving inoculation recession

Inactive Publication Date: 2015-11-11

濮阳市中壹电子科技有限公司

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Low carbon equivalent and high strength will cause the following problems: (1) large shrinkage, resulting in increased shrinkage cavity and shrinkage tendency; (2) large residual stress, resulting in poor dimensional accuracy stability and increased cracking tendency; (3) poor fluidity, Limits the thinning of castings; (4) Poor processing performance, resulting in a reduction in cutting speed and a decrease in tool life

In addition, in order to improve the strength of gray cast iron, a large amount of chromium, copper, and molybdenum alloys are added, which not only increases the cost, but also leads to excessive cementite content, deterioration of processing performance, and easy cracking of castings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0020] Example 1 The chemical composition and its weight percentage are: Si: 30-40%, Mn10-20%, Cr10-20, C<0.1%, Ca1-5%, Ba1-6%, N1-6%, P<0.05% , S<0.02%, the rest is Fe.

[0021] The preparation method is a mechanical mixing method: after crushing ferrochromium nitride, ferromanganese nitride, silicon calcium, and silicon barium alloy into 1-10mm particles, they are mixed in proportion.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

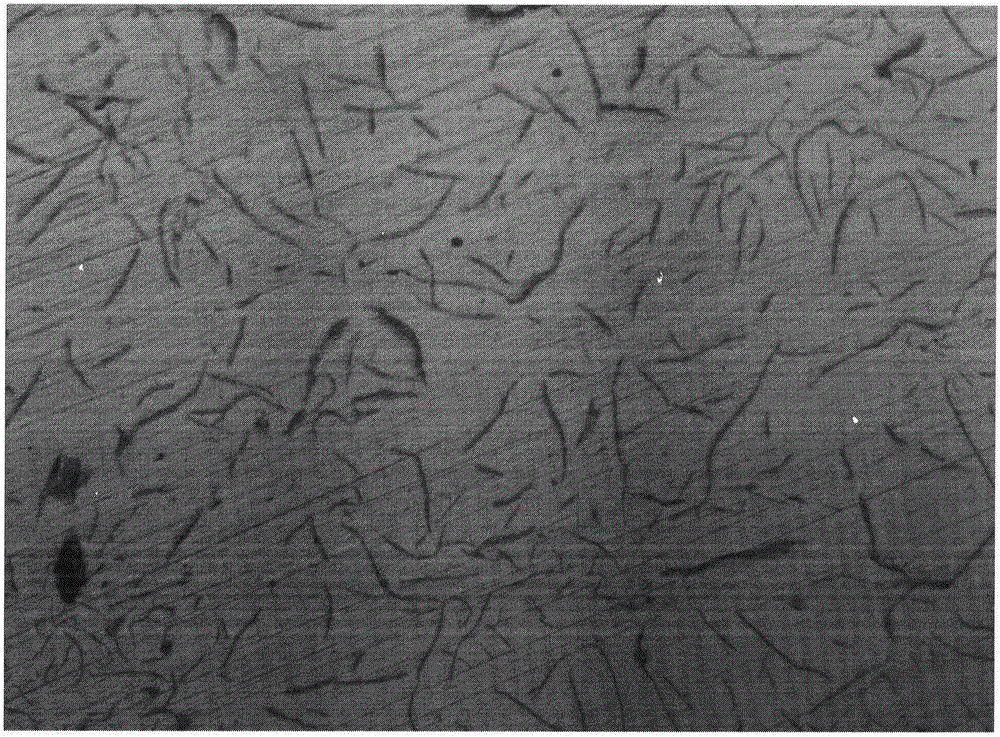

The present invention discloses an inoculant for increasing the strength of gray cast iron, a preparation method and a use method thereof, and belongs to the technical field of casting. According to the present invention, nitrogen is adopted as an alloy element so as to significantly refine graphite, change graphite morphology, reduce structure wall thickness sensitivity and significantly increase the pearlite content, such that the tensile strength of the gray cast iron is improved, and especially the significant effects are provided for the high-carbon equivalent gray cast iron or high-carbon gray cast iron; the chemical components of the inoculant comprise, by weight, 25-35% of Si, 10-20% of Mn, 10-20% of Cr, less than 0.1% of C, 1-5% of Ca, 1-6% of Ba, 1-6% of N, less than 0.05% of P, less than 0.02% of S, and the balance of Fe; and for the original hot metal having the same components, compared with the ferrosilicon inoculants, the tensile strength of the gray cast iron can be improved by 30-80 MPa with the inoculant of the present invention.

Description

Technical field [0001] The invention belongs to the technical field of casting, and in particular relates to an inoculant for increasing the strength of gray cast iron, a preparation method and a use method thereof. Background technique [0002] Inoculation in modern cast iron production is one of the most important ways to improve the performance of cast iron. With the development of casting technology, inoculation treatment becomes more and more important. [0003] With the development of the machinery industry, the requirements for the strength of gray cast iron are getting higher and higher. In particular, it is necessary to achieve high tensile strength with high carbon equivalent or high carbon content. In order to improve the strength of gray cast iron, some companies have adopted methods to reduce the carbon equivalent. Low carbon equivalent and high strength will cause the following problems: (1) Large shrinkage leads to increased shrinkage and shrinkage tendency; (2) La...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C1/08C22C33/08

Inventor 刘南陔孙玉福万海涛高昭龙

Owner 濮阳市中壹电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com