Unsaturated resin-based composite material, preparation method and applications thereof

A composite material and unsaturated technology, applied in the field of unsaturated resin-based composite materials and their preparation, can solve the problems of aggravated mold wear, limited heat conduction direction, wear of contact parts, etc., so as to improve product quality, avoid excessive hardness, Compatibility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

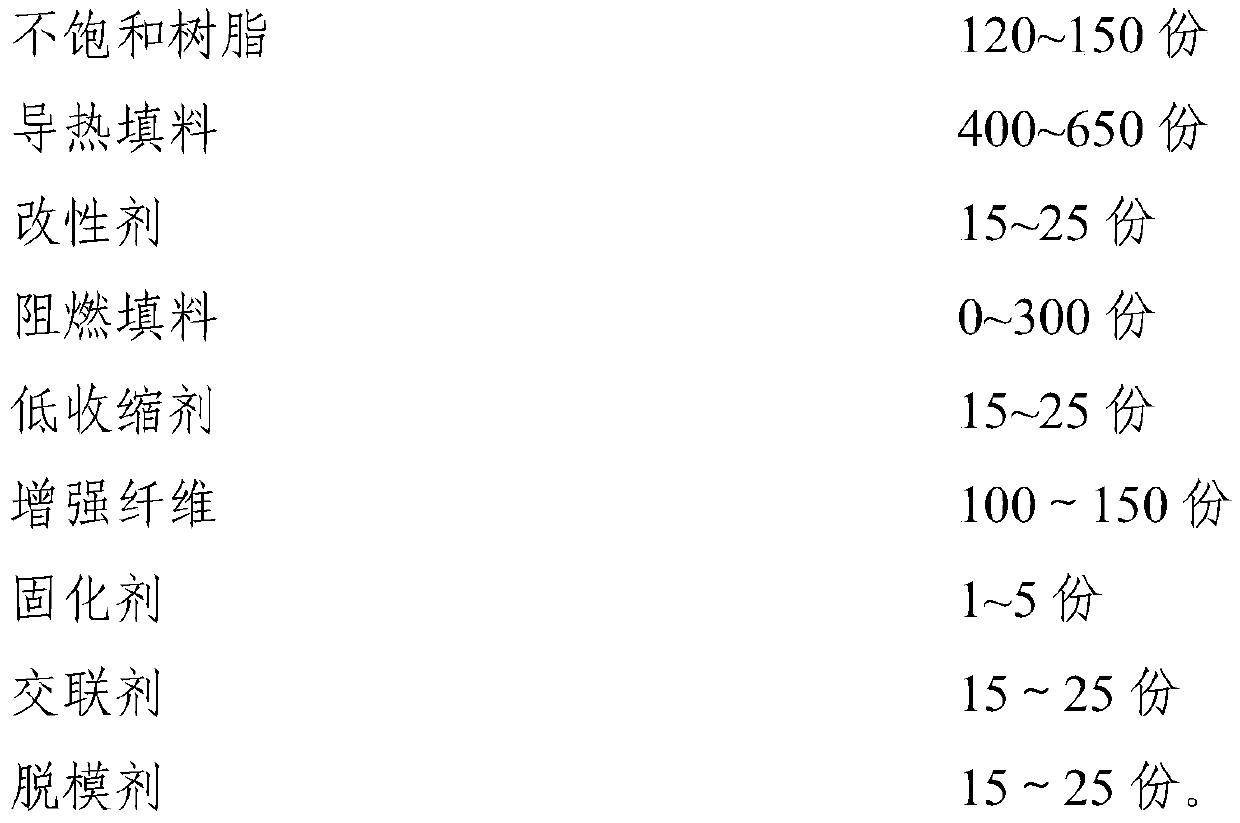

[0044] In order to illustrate the effects by comparison, the present invention is verified by different formulations of bulk molding compounds and their implementation effects. The formulations of the examples and comparative examples are shown in Table 1 below. In the following examples, the amounts of each component are the mass amounts.

[0045] Table 1

[0046]

[0047] The preparation process of each bulk molding compound in the above table is as follows:

[0048] Add unsaturated polyester resin, crosslinking agent, curing agent, low shrinkage agent, modifier (do not add if "—" is displayed in the table) and mold release agent in sequence in the double-arm kneader, and the blades are reversed 2-5 minutes, then add thermally conductive fillers and / or flame-retardant fillers according to the formula (do not add if "—" is display...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com