Preparation method of inorganic high molecular abrasive tool

A technology of inorganic polymers and abrasive tools, applied in the direction of grinding/polishing equipment, abrasive materials, grinding devices, etc., can solve the problems of unstable chemical properties, complicated production process, easy burning of abrasive tools, etc., and achieve unique functions, sticky High bonding strength and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with the present invention do further explanation:

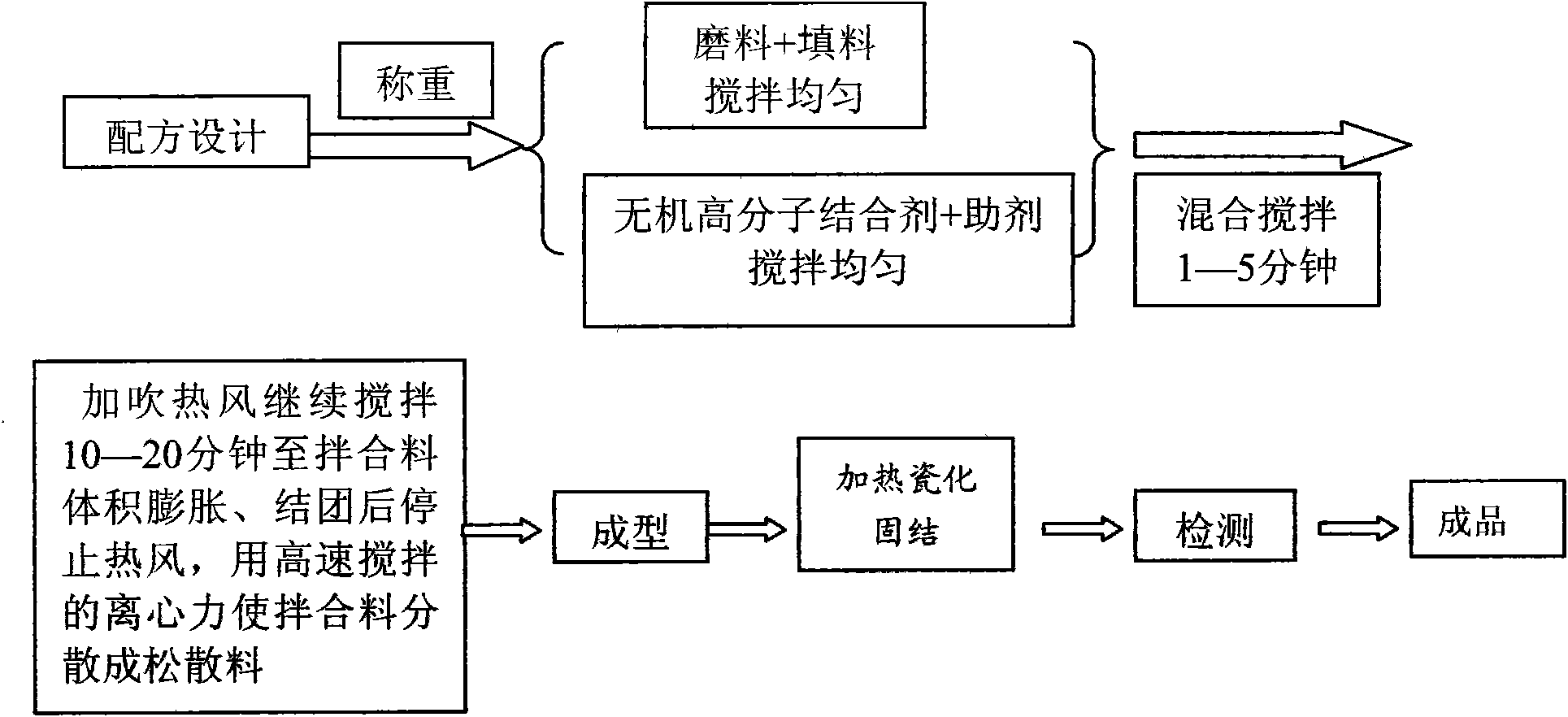

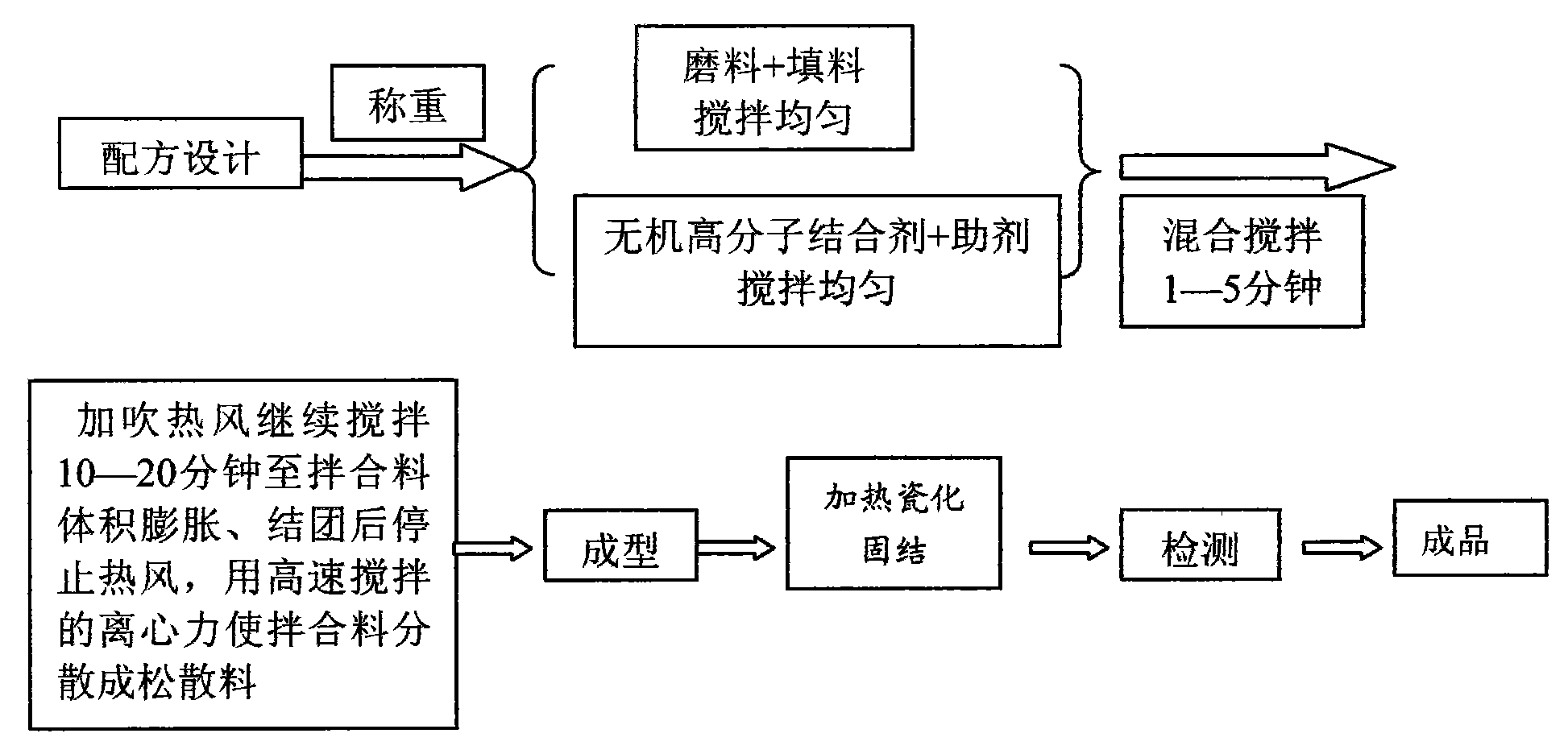

[0049] The preparation method of the inorganic polymer abrasive tool provided by the present invention realizes the forming of the abrasive tool through the following steps, specifically as follows:

[0050] a. Design the formula of the product according to the product standard;

[0051] b. Weigh the designed formula according to the proportion;

[0052] c. Stir the abrasives and fillers in the formula evenly; when the abrasives are used in conjunction with the inorganic polymer binder, first treat the acidic components on the surface of the abrasives, where the abrasives are corundum abrasives, silicon carbide, silicon nitride, and diamond abrasives ; Wherein the filler is iron oxide, copper powder, silicon carbide, iron sulfide, wollastonite or inorganic mineral pigment.

[0053] d. Stir the inorganic polymer binder and auxiliary agent in the formula evenly to form a mixture; the inorganic pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com