7075 aluminum alloy and preparation method and application thereof

An aluminum alloy and intermediate alloy technology, applied in the field of aluminum alloys, can solve the problems of weakening the deformation processing performance of materials, the mechanical properties of deformed parts, the poor stress corrosion resistance of 7075 aluminum alloys, and restricting the application of 7075 aluminum alloys, so as to reduce precipitation and precipitation. , Improve stress corrosion resistance, reduce the effect of free vacancy concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Accordingly, the present application also provides the preparation method of the above 7075 aluminum alloy, including the step of: smelt and semi-continuous casting of 7075 aluminum alloy according to the composition and content of the 7075 aluminum alloy.

[0050] Among them, the raw material of 7075 aluminum alloy mainly includes: pure Al, pure Zn, pure Mg, pure Cu, pure GE, AlCr intermediate alloy, ALER intermediate alloy, ALGD intermediate alloy and Alti intermediate alloy.

[0051] In a reference, the smelting process of the present application can include adding pure Al, pure Zn, pure Cu, AlCr intermediate alloy to smelt in the smelting furnace, the melting temperature is 750-800 ° C; after being completely melted, add ALGD intermediate alloy, sufficient After stirring; 10-15 minutes, add aler intermediate alloy, thoroughly stir it; after it is completely melted, add pure GE, stir well; add pure Mg, thoroughly, thoroughly, after it is completely melted, followed by: A...

Embodiment 1

[0069] This embodiment provides a 7075 aluminum alloy ingot having a diameter of 127 mm, with a mass percentage meter, and the composition and content thereof are as follows: 5.7% ≤ zn ≤ 5.8%, 2.2% ≤ mg ≤ 2.2%, 1.2% ≤ C ≤ 1.3 %, 0.19% ≤ C ≤ 0.21%, 0.18% ≤ Er≤0.21%, 0.09% ≤ agd ≤ 0.12%, 0.04% ≤ concate ≤ 0.07%, Mn ≤ 0.15%, Si ≤ 0.25%, Fe≤0.25%, Ti ≤0.18%, other impurity elements of the single content ≤ 0.05%, and the total amount of other impurity elements is ≤0.11%, the remaining amount is Al.

[0070] The preparation process of the 7075 aluminum alloy ingot is as follows:

[0071]Slubging: According to the above chemical elements, pure Al (purity 99.95%) in the corresponding raw material, pure Zn (purity is 99.95%), pure Cu (purity is 99.5%) and Al-10CR intermediate alloy placed in a smelting furnace Heating, the initial heating temperature is 800 ° C; after the above substance is completely melted, the temperature will be reduced to 780 ° C, and the addition of the Al-10GD inter...

Embodiment 2

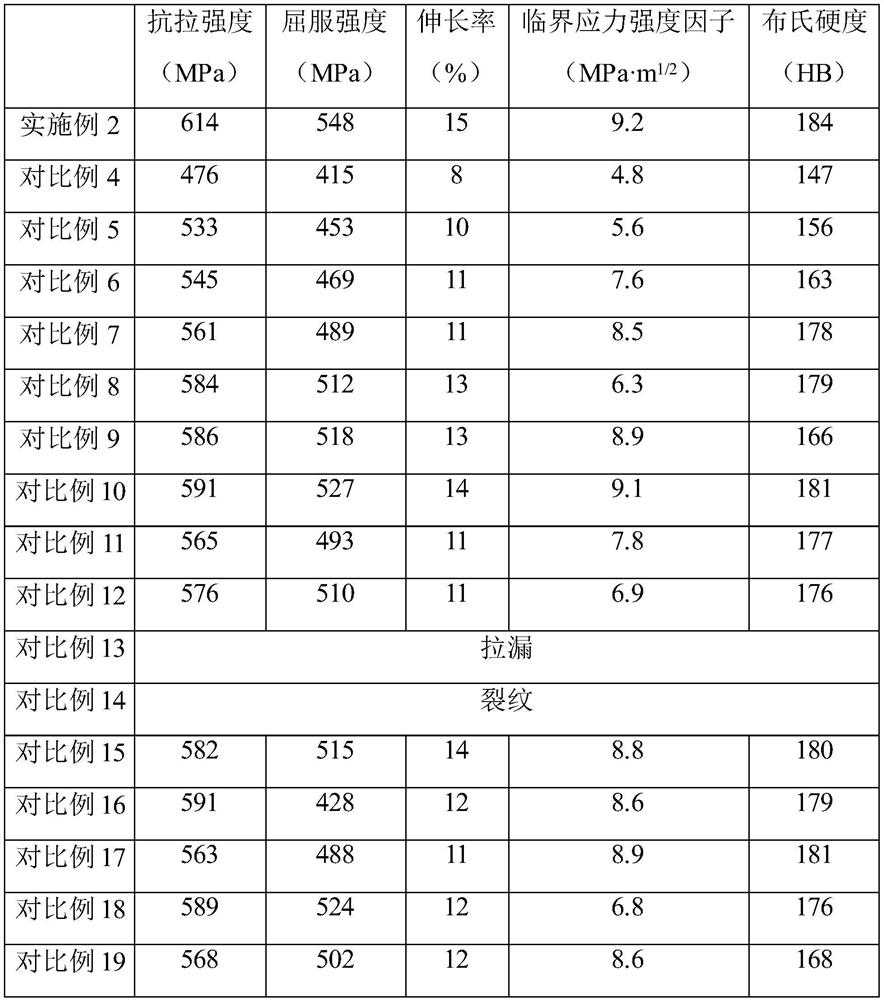

[0084] This embodiment provides a batch of 7075 aluminum alloy ingot having a batch of 300 mm, with a mass percentage measurement and content satisfying: 5.9% ≤ zn ≤ 6.1%, 2.2% ≤ mg ≤ 2.4%, 1.3% ≤ C ≤ 1.4 %, 0.18% ≤ C ≤ 0.2%, 0.25% ≤ EER ≤ 0.28%, 0.13% ≤ Gd ≤ 0.08%, 0.05% ≤ concate ≤ 0.08%, Mn ≤ 0.1%, Si ≤ 0.1%, Fe ≤ 0.1%, Ti ≤0.1%, other impurity elements of the single content ≤ 0.03%, the total amount of other impurity elements is ≤0.1%, the margin is Al.

[0085] The preparation process of the 7075 aluminum alloy ingot is as follows:

[0086] Pure Al (purity was 99.99%), pure Zn (purity was 99.99%), pure Cu (purity of 99.99%) and Al-10CR intermediate alloy were placed in a smelting furnace, and the initial heating temperature was set to 800 ° C, which was heated. The heating temperature was reduced to 780 ° C 8 hours. After it is completely melted, add the Al-10GD intermediate alloy to the smelting furnace, stirred for 15 min, add the Al-10er intermediate alloy, stir well 20 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com