Preparation method of high-strength and corrosion-resistant Al-Y-Sc alloy and Al-Y-Sc alloy

An al-y-sc, corrosion-resistant technology, applied in the field of aluminum alloy preparation, can solve the problems of insufficient basic research and difficult performance, and achieve the goal of improving thermal stability and heat resistance, improving weldability, and improving fracture toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

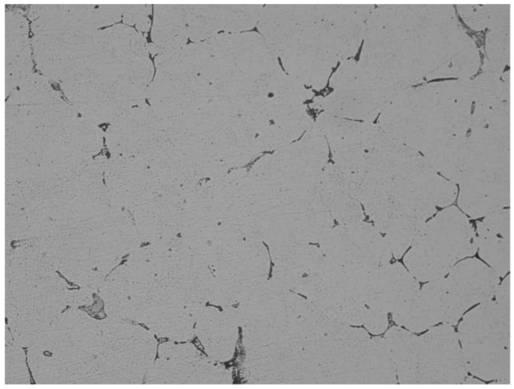

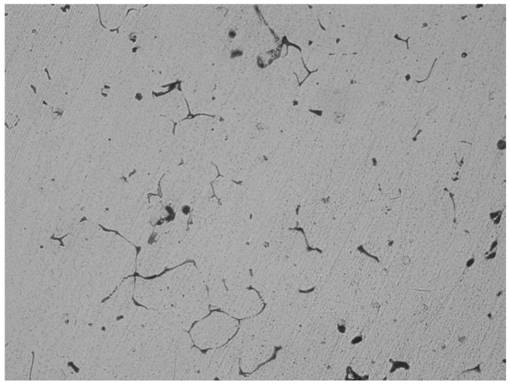

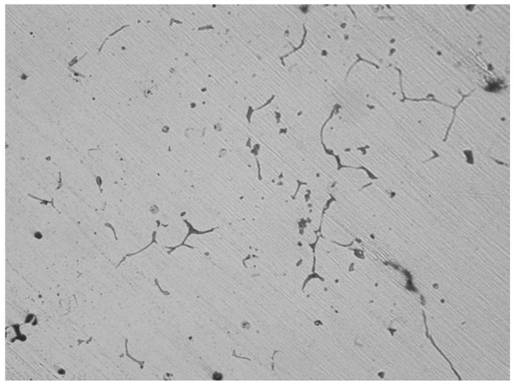

Image

Examples

Embodiment 1

[0038] A preparation method of a high-strength corrosion-resistant Al-Y-Sc alloy, comprising the following steps:

[0039] S1: Preparation of alloy ingot: Prepare 500g of raw materials according to the following mass percentages: Components in mass percentages: Sc0.01%, Cu 2.0%, Mg 1.8%, Y 0.25%, Zn 7.6%, Fe 0.15%, Cr 0.04%, Ti 0.06%, Mn 0.05%, Zr 0.08%, and the balance is Al; Cu, Sc, Zr, Y, Fe, Cr, Ti, Mn are made into master alloys with Al respectively, and the mass ratio is 7:3. Mg is divided into two parts, and the master alloys Al-Cu, Al-Sc, Al-Zr, Al-Y, Al-Fe, Al-Cr, Al-Ti, Al-Mn are smelted with pure Zn and high-purity Al. Wrap the first part of Mg with aluminum foil, cover it with a bell jar and press it into the bottom of the melt, take out the bell jar after it is completely melted, add 1g of Al-Ti-B grain refiner after the furnace charge is completely melted, and let it stand for 10 minutes Add 10g of hexachloroethane for degassing once; then wrap the second Mg wit...

Embodiment 2

[0042] A preparation method of a high-strength corrosion-resistant Al-Y-Sc alloy, comprising the following steps:

[0043] S1: Preparation of alloy ingot: Prepare 500g of raw materials according to the following mass percentages: Components in mass percentages: Sc0.25%, Cu 2.3%, Mg 2.0%, Y 0.25%, Zn 8.0%, Fe 0.15%, Cr 0.04%, Ti 0.06%, Mn0.05%, Zr 0.15%, and the balance is Al; Cu, Sc, Zr, Y, Fe, Cr, Ti, Mn are made into master alloys with Al respectively, and the mass ratio is 7:3. Mg is divided into two parts, and the master alloys Al-Cu, Al-Sc, Al-Zr, Al-Y, Al-Fe, Al-Cr, Al-Ti, Al-Mn are smelted with pure Zn and high-purity Al. Wrap the first part of Mg with aluminum foil, cover it with a bell jar and press it into the bottom of the melt, take out the bell jar after it is completely melted, add 2g of Al-Ti-B grain refiner after the furnace charge is completely melted, and then let it stand Add 20g of hexachloroethane in 15 minutes for degassing; then wrap the second part of ...

Embodiment 3

[0046] A preparation method of a high-strength corrosion-resistant Al-Y-Sc alloy, comprising the following steps:

[0047] S1: Preparation of alloy ingot: Prepare 500g of raw materials according to the following mass percentages: Components in mass percentages: Sc0.35%, Cu 2.6%, Mg 2.3%, Y 0.25%, Zn 8.4%, Fe 0.15%, Cr 0.04%, Ti 0.06%, Mn 0.05%, Zr 0.25%, the balance is Al; Cu, Sc, Zr, Y, Fe, Cr, Ti, Mn are made with Al respectively, and Mg is divided according to the mass ratio of 7:3 In two parts, the master alloys Al-Cu, Al-Sc, Al-Zr, Al-Y, Al-Fe, Al-Cr, Al-Ti, Al-Mn were smelted with pure Zn and high-purity Al, and the second Wrap a piece of Mg with aluminum foil, cover it with a bell jar and press it into the bottom of the melt, take out the bell jar after it is completely melted, add 3g of Al-Ti-B grain refiner after the furnace charge is completely melted, and let it stand for 10-20min Add 30g of hexachloroethane for one degassing; then wrap the second part of Mg with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com