A laser hybrid welding emitting device

A hybrid welding and laser welding head technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of heavy thermal crack tendency, welding pores, and welding spatter, etc., so as to reduce the solidification speed and reduce pores , Reduce the effect of welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

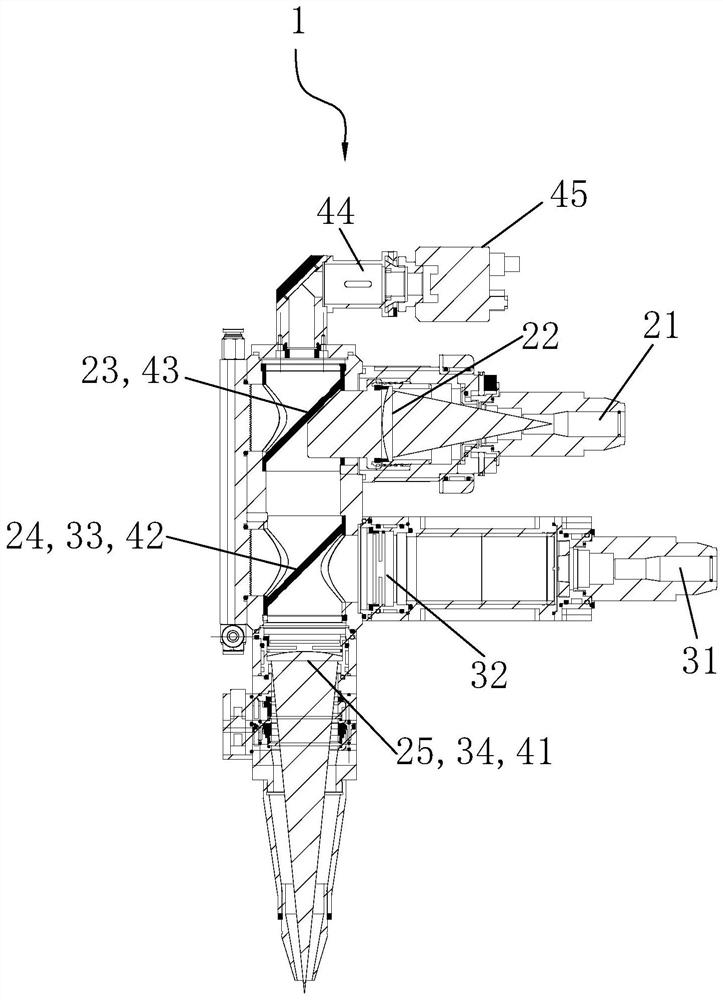

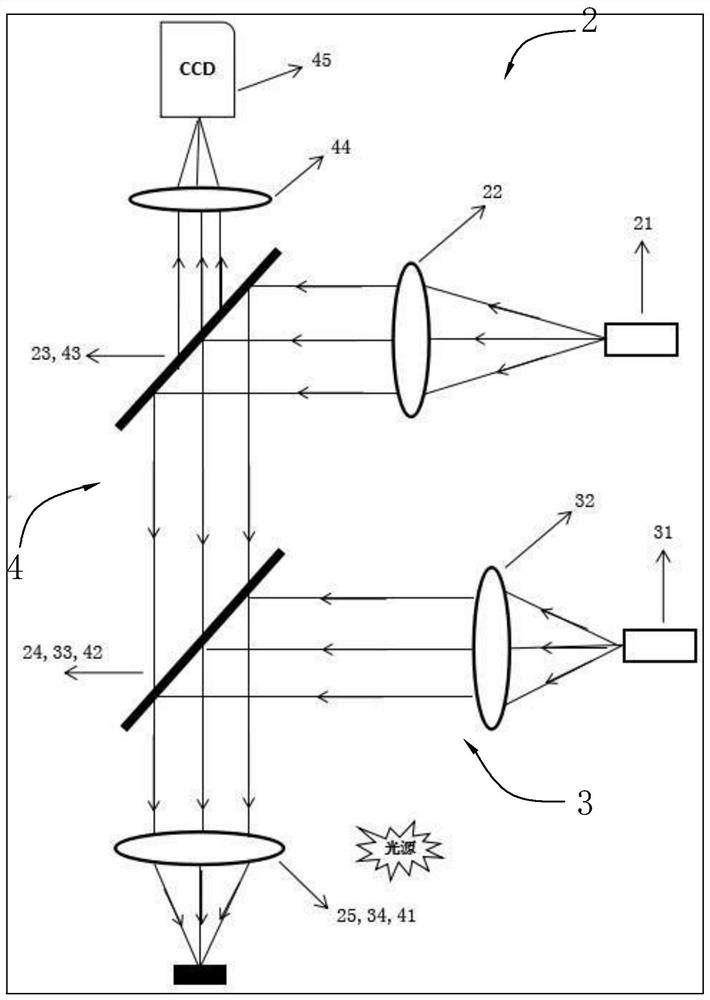

[0026] Such as Figure 1-9 As shown, the laser hybrid welding emitting device of the present invention includes a laser welding head 1, a semiconductor laser (not shown in the figure), and a fiber laser (not shown in the figure). The semiconductor laser and fiber laser are respectively connected to the laser welding head 1, the semiconductor laser is used to emit semiconductor laser to the laser welding head, and the fiber laser is used to emit fiber laser to the laser welding head. Such as figure 1 , figure 2 As shown in this embodiment, the optical path of the laser welding head 1 includes: a semiconductor optical path 2 , an optical fiber optical path 3 and a coaxial monitoring optical path 4 . The laser beam of the semiconductor optical path 2 and the laser beam of the optical fiber optical path 3 are focused at the focal point of the laser welding head, and combined into one beam for welding, and the welding position is illuminated by an external light source, and the ...

Embodiment 2

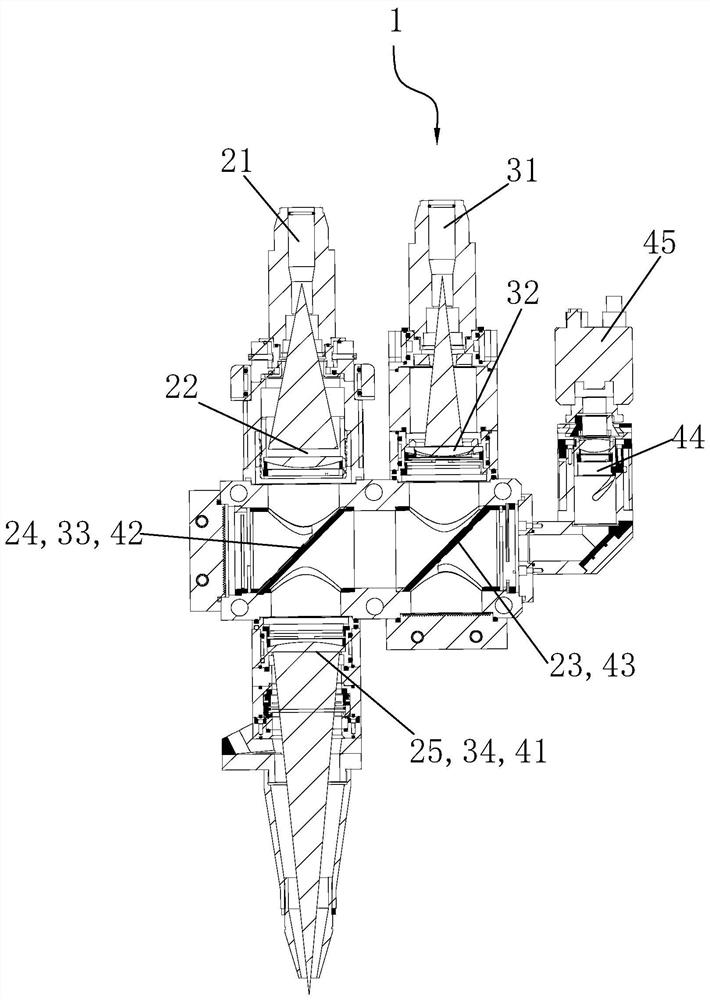

[0037] like image 3 , Figure 4 As shown, the basic structure, function and optical path composition of this embodiment are the same as those of Embodiment 1, the only difference lies in the placement of components on the laser head, and the basic structure of Embodiment 2 will not be elaborated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com