Nuclear-grade nickel-chromium-iron alloy welding wire as well as preparation method and application thereof

A ferroalloy, nickel-chromium technology, applied in the field of nuclear-grade nickel-chromium-iron alloy welding wire and its preparation, can solve the problems of increasing the difficulty of welding construction, uneven alloy composition, and easy formation of segregation, so as to improve the effect of strengthening and crack resistance, and improve the strength Toughness combination, the effect of improving the uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of above-mentioned nuclear-grade nickel-chromium-iron alloy welding wire, comprises the steps:

[0065] S1, alloy smelting, alloy raw materials are obtained by vacuum smelting to obtain steel ingots;

[0066] Specifically include the following steps:

[0067] S11, ingredients, according to the composition and mass percentage of alloy raw materials, C≤0.040%, Mn≤3.50%, Fe: 6.00~13.00%, P≤0.010%, S≤0.008%, Si: 0.05~1.00%, Cu≤ 0.10%, Al: 0.05~1.00%, Ti: 0.05~1.10%, Cr: 26.0~34.5%, Nb: 0.05~1.20%, Co≤0.02%, N≤0.030%, Zr≤0.02%, V: 0.05~ 1.00%, Ta: 0.05~0.50%, B≤0.005%, the balance is Ni, for batching;

[0068] S12, vacuum smelting, derusting and baking the alloy raw materials, put them into the vacuum induction furnace, vacuum the vacuum induction furnace, and use high power to smelt under the condition of vacuum degree ≤ 2.6Pa, after all the alloy raw materials are melted into molten steel , reduce the power for heat preservation and refining for 3...

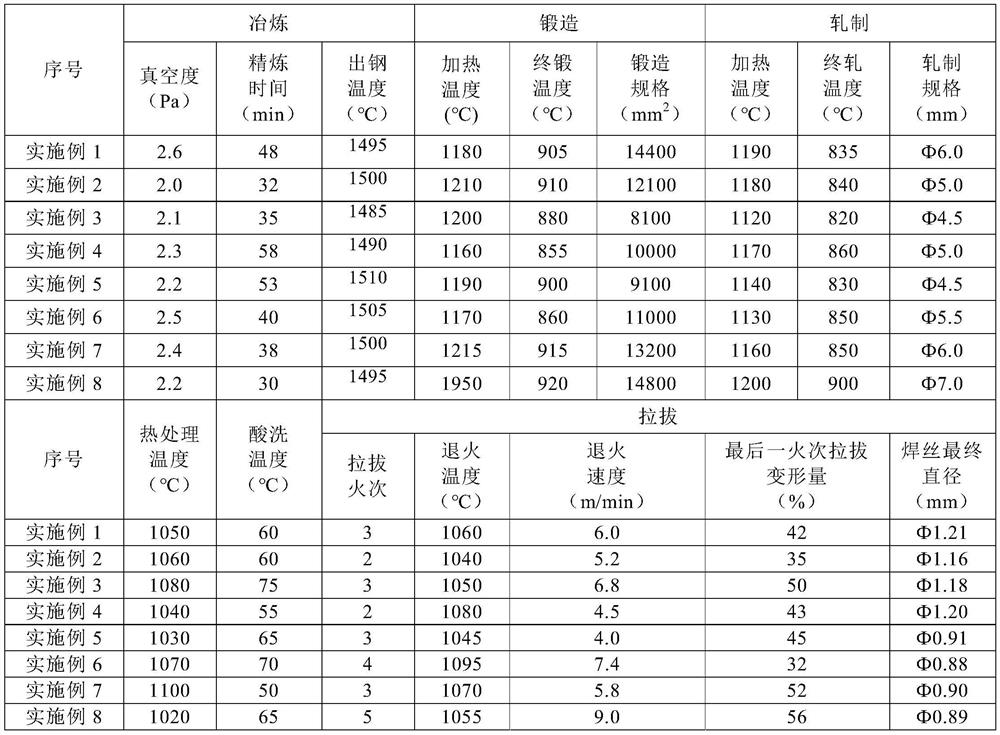

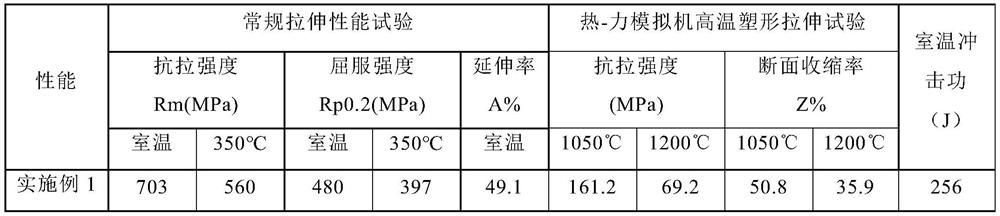

Embodiment 1

[0082] According to the requirements of each element composition and mass percentage of the nuclear-grade nickel-chromium-iron alloy welding wire in Example 1 in Table 1, the alloy raw materials are derusted and baked, then added to the vacuum induction furnace, and then vacuumed to a vacuum degree of 2.6Pa. Carry out smelting, heat preservation and refining for 48 minutes after all the alloy raw materials are melted, adjust the composition to reach the various element compositions and mass percentages of the nuclear-grade nickel-chromium-iron alloy welding wire of Example 1 in Table 1, and then cast steel ingots, and the tapping temperature is 1495°C.

[0083] The steel ingot is used as the electroslag remelting electrode and refined in an Ar atmosphere electroslag remelting furnace. The electroslag is made of Al 2 o 3 -CaF 2 -CaO-MgO slag system ensures the refining effect; the steel ingot is heated to 1180°C and forged to a cross-sectional area of 14400mm 2 The final fo...

Embodiment 2~8

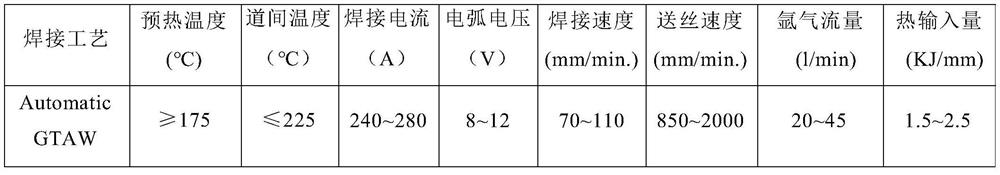

[0087] The nuclear-grade nickel-chromium-iron alloy welding wire in Examples 2 to 8 is batched according to the elemental components and mass percentages in the nuclear-grade nickel-chromium-iron alloy welding wire in Table 1. The specific steps are the same as those in Example 1, and the key process parameters are carried out in accordance with Table 2. preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com