Aluminium alloy used for automobile anti-collision beam, and manufacturing method for product thereof

A technology of an aluminum alloy product and a manufacturing method, which is applied in the field of Al-Zn-Mg-Cu series aluminum alloy and its product manufacturing for automobile anti-collision beams, and achieves the effects of low hardenability, improved corrosion resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

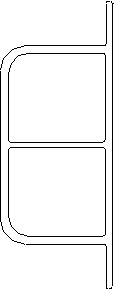

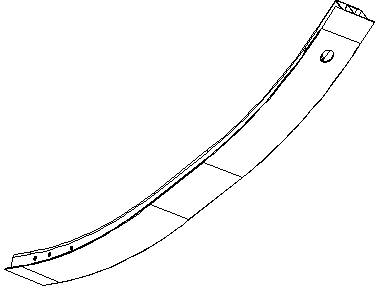

Image

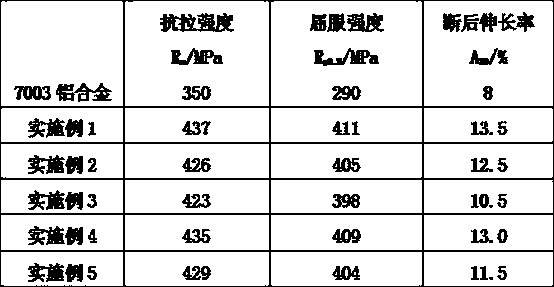

Examples

Embodiment 1

[0040] First cast ingots according to the mass percentage of the aluminum alloy composition, the composition of the ingots is calculated by mass percentage (sampling and analyzing the chemical composition in the casting flow table): zinc (Zn) 6.80%, magnesium (Mg) 1.05%, copper ( Cu) 0.26%, zirconium (Zr) 0.17%, manganese (Mn) 0.12%, titanium (Ti) 0.012%, chromium (Cr) 0.02%, iron (Fe) 0.22%, silicon (Si) 0.18%, the balance is Aluminum (Al). It can be cast into an ingot by melting and then direct chilling or other conventional casting techniques, and the diameter of the ingot is Ф240mm.

[0041] Next, the cast ingot was homogenized and heated, and after being homogenized and heat-preserved at a temperature of 460° C. for 8 hours, it was taken out of the furnace and air-cooled to room temperature.

[0042] Then, the ingot is sawed into the extruded ingot according to the required length (low-magnification and high-magnification samples are taken), and it is sent into the induc...

Embodiment 2

[0046] First cast ingots according to the mass percentage of the aluminum alloy composition, the composition of the ingots is calculated by mass percentage (sampling and analyzing the chemical composition in the casting flow table): zinc (Zn) 6.65%, magnesium (Mg) 0.95%, copper ( Cu) 0.25%, zirconium (Zr) 0.18%, manganese (Mn) 0.10%, titanium (Ti) 0.014%, chromium (Cr) 0.03%, iron (Fe) 0.19%, silicon (Si) 0.15%, the balance is Aluminum (Al). It can be cast into an ingot by melting and then direct chilling or other conventional casting techniques, and the diameter of the ingot is Ф240mm.

[0047] Next, the cast ingot was homogenized and heated, and after homogenized heating at a temperature of 450° C. for 7 hours, it was taken out of the furnace and air-cooled to room temperature.

[0048] Then, the ingot is sawed into the extruded ingot according to the required length (low-magnification and high-magnification samples are taken), and it is sent into the induction furnace and ...

Embodiment 3

[0052] First cast ingots according to the mass percentage of the composition of the aluminum alloy, the composition of the ingots is calculated according to the mass percentage (sampling and analyzing the chemical composition in the casting flow table): zinc (Zn) 6.55%, magnesium (Mg) 0.90%, copper ( Cu) 0.20%, zirconium (Zr) 0.20%, manganese (Mn) 0.15%, titanium (Ti) 0.01%, chromium (Cr) 0.01%, iron (Fe) 0.25%, silicon (Si) 0.20%, the balance is Aluminum (Al). It can be cast into an ingot by melting and then direct chilling or other conventional casting techniques, and the diameter of the ingot is Ф240mm.

[0053] Next, the cast ingot was homogenized and heated for 9 hours at a temperature of 460° C., and then it was taken out of the furnace and air-cooled to room temperature.

[0054] Then, the ingot is sawed into the extruded ingot according to the required length (low-magnification and high-magnification samples are taken), and it is sent into the induction furnace and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com