Hot isostatic pressing treatment process method for casting forming ZL101A aluminum alloy

A ZL101A, hot isostatic pressing technology, applied in the field of aluminum alloy casting and heat treatment, can solve the problems of reduced mechanical properties and corrosion properties of aluminum alloy materials, fast cooling rate at high temperature, poor mechanical properties at room temperature, etc., to save production cycle, The effect of reducing the porosity and shrinkage rate and reducing the critical cooling rate of quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a hot isostatic pressing process method for casting ZL101A aluminum alloy, including:

[0054] Step 1: ZL101A aluminum alloy casting casting;

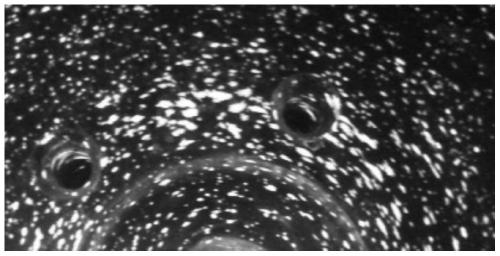

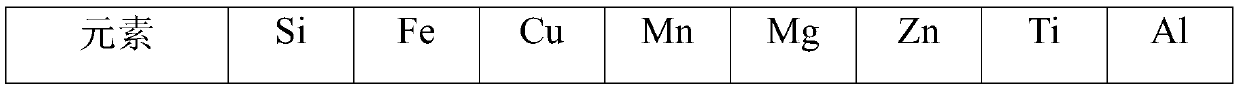

[0055] Aluminum alloy ingots are used as raw materials. The composition of aluminum alloy ingots is shown in Table 1. Furan resin is used as raw material to make sand molds. Al-10Sr alloy is added as a modifier to control the Sr content of about 0.03% (wt). Melt in the graphite crucible. After all the melting, the temperature is controlled at 730°C to 750°C for refining and degassing. After degassing, let it stand for 10 minutes, cool down to 710°C and cast it into a cast rod with a diameter of 20mm.

[0056] Table 1: Composition of the ZL101A aluminum alloy used

[0057]

[0058]

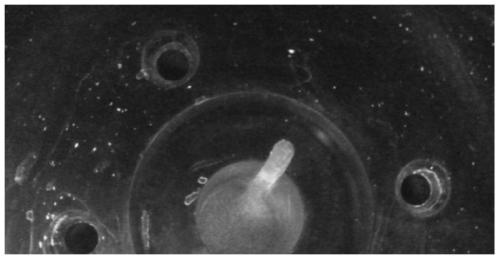

[0059] Step 2: Hot isostatic pressing treatment of ZL101A aluminum alloy castings;

[0060] The ZL101A aluminum alloy casting is heated from room temperature to 540°C with a heating rate of 0.15K / s, kept at 540°C and ...

Embodiment 2

[0062] In Example 2, the same hot isostatic pressing machine as in Example 1 and the process of casting ZL101A aluminum alloy castings are adopted. The difference from Example 1 is that the ZL101A aluminum alloy castings are heated from room temperature to 530 ° C, and the temperature rises The speed is 0.12K / s, heat preservation and pressure at 540°C and 80MPa for 2h, cool down to 180°C at a speed of 1K / s, control the pressure at 70-80MPa during the cooling process, cool to 180°C in a hot isostatic pressing furnace Carry out artificial aging within 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com