Process for preventing hot-rolling edge cracking of oriented silicon steel

A technology for oriented silicon steel and edge cracking, which is applied in the field of preventing edge cracking during hot rolling of oriented silicon steel, and can solve problems such as the occurrence of edge cracking in oriented silicon steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

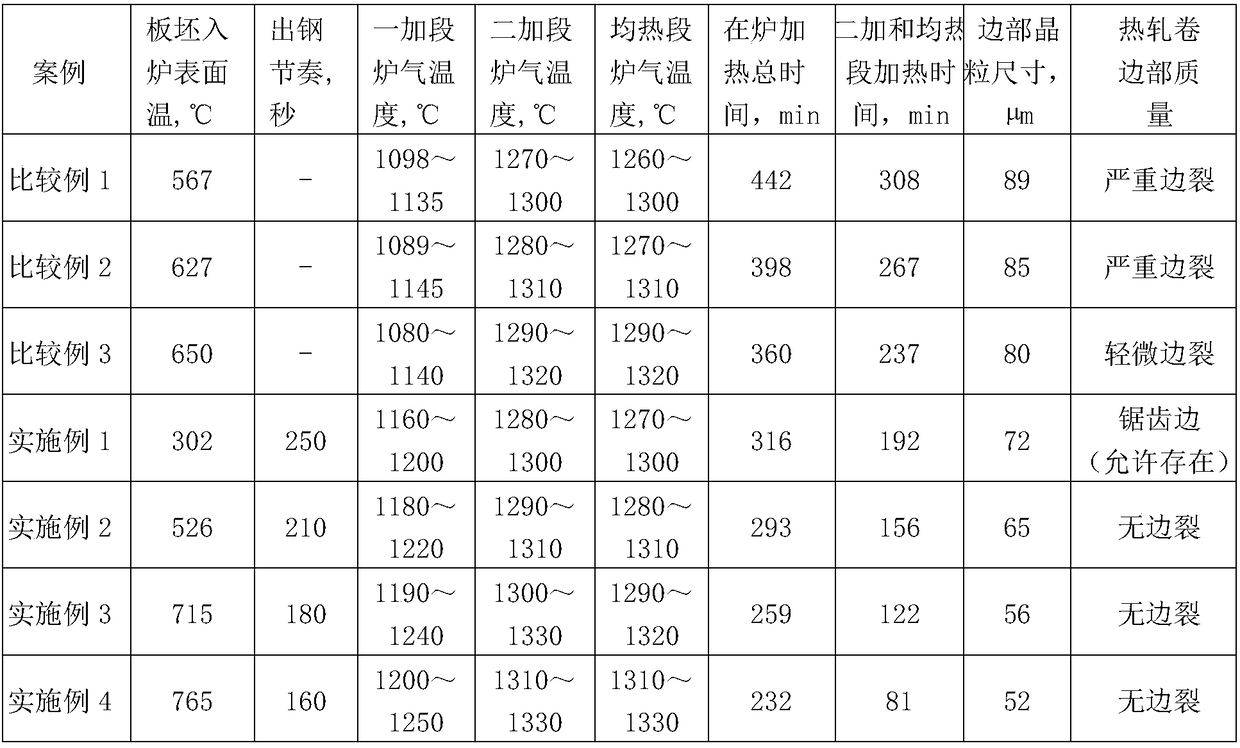

Examples

Embodiment 1

[0073] The present embodiment is produced on a 1580mm hot continuous rolling line, and the heating furnace is two walking heating furnaces, which alternately tap steel. The production process steps are as follows:

[0074] Step 1: Steelmaking and continuous casting to obtain a grain-oriented silicon steel slab with a thickness of 230mm and a width of 1310mm. Al: 0.022%, N: 0.0092%, and the remaining elements are Fe and unavoidable residual elements in steel;

[0075] Step 2: The slab continuous casting ends at 8:31 minutes, the intermediate residence time is 9 hours and 58 minutes, the heating furnace starts at 18:29 minutes, and the surface temperature of the slab is measured at 302°C when entering the furnace;

[0076] Step 3: From the first slab into the furnace, the hot rolling tapping rhythm is 250 seconds to tap a piece of steel, and the two furnaces tap alternately;

[0077] Step 4: After the slab enters the first heating section, control the temperature of the furnace...

Embodiment 2

[0089] The present embodiment is produced on a 1580mm hot continuous rolling line, and the heating furnace is two walking heating furnaces, which alternately tap steel. The production process steps are as follows:

[0090] Step 1: steelmaking and continuous casting to obtain a grain-oriented silicon steel slab with a thickness of 230mm and a width of 1060mm. Al: 0.021%, N: 0.0098%, and the remaining elements are Fe and unavoidable residual elements in steel;

[0091] Step 2: The slab continuous casting ends at 11:25 minutes, the intermediate residence time is 5 hours and 20 minutes, the heating furnace starts at 16:45 minutes, and the surface temperature of the slab is measured at 526°C when entering the furnace;

[0092] Step 3: From the first slab into the furnace, the hot rolling tapping rhythm is 210 seconds to tap a piece of steel, and the two furnaces tap alternately;

[0093] Step 4: After the slab enters the first heating section, control the temperature of the furnac...

Embodiment 3

[0105] The present embodiment is produced on a 1580mm hot continuous rolling line, and the heating furnace is two walking heating furnaces, which alternately tap steel. The production process steps are as follows:

[0106] Step 1: Steelmaking and continuous casting to obtain a grain-oriented silicon steel slab with a thickness of 230 mm and a width of 1310 mm. Al: 0.023%, N: 0.0068%, and the remaining elements are Fe and unavoidable residual elements in steel;

[0107] Step 2: The slab continuous casting ends at 20:55 minutes, the intermediate residence time is 3 hours and 01 minutes, the heating furnace starts at 23:56 minutes, and the surface temperature of the slab is measured at 715°C when entering the furnace;

[0108] Step 3: From the first slab into the furnace, the hot rolling tapping rhythm is 180 seconds to tap a piece of steel, and the two furnaces tap alternately;

[0109] Step 4: After the slab enters the first heating section, control the temperature of the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com