Aluminum alloy panel for aviation and production method of aluminum alloy panel

A technology of an aluminum alloy sheet and a production method, which is applied in the field of aluminum alloy sheet production, can solve problems such as uneven performance of domestic sheets, and achieve the effects of increased fracture toughness, uniform comprehensive performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

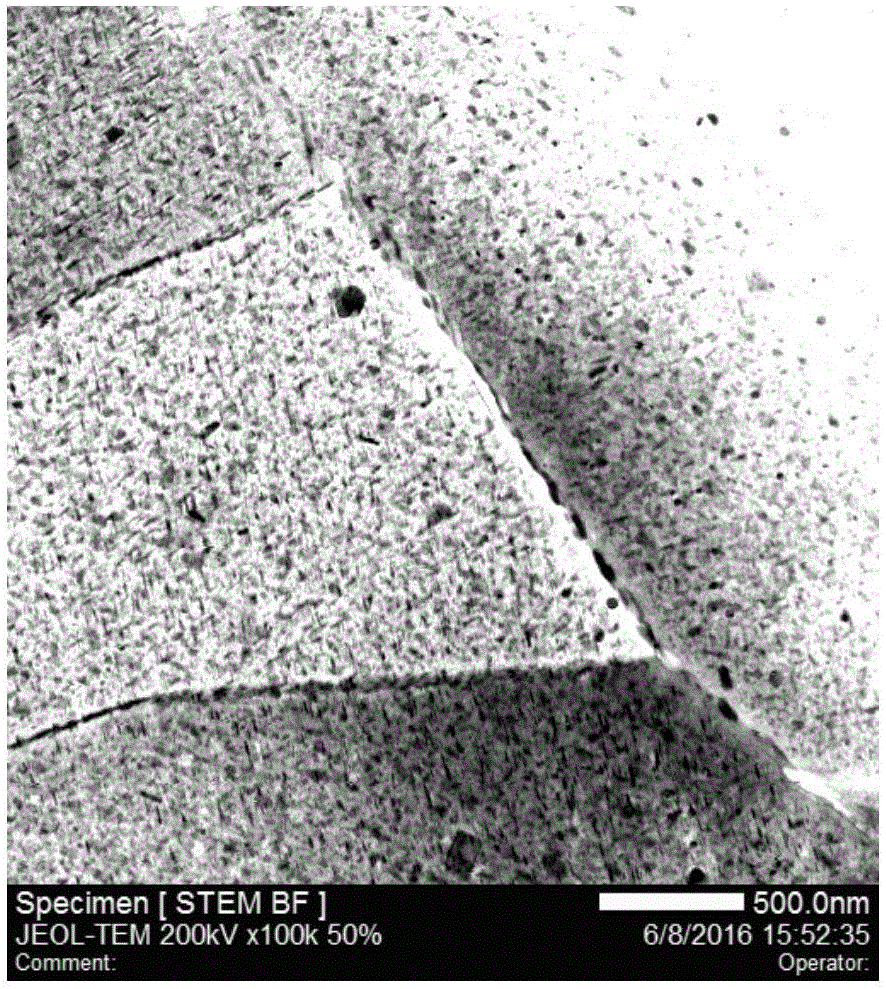

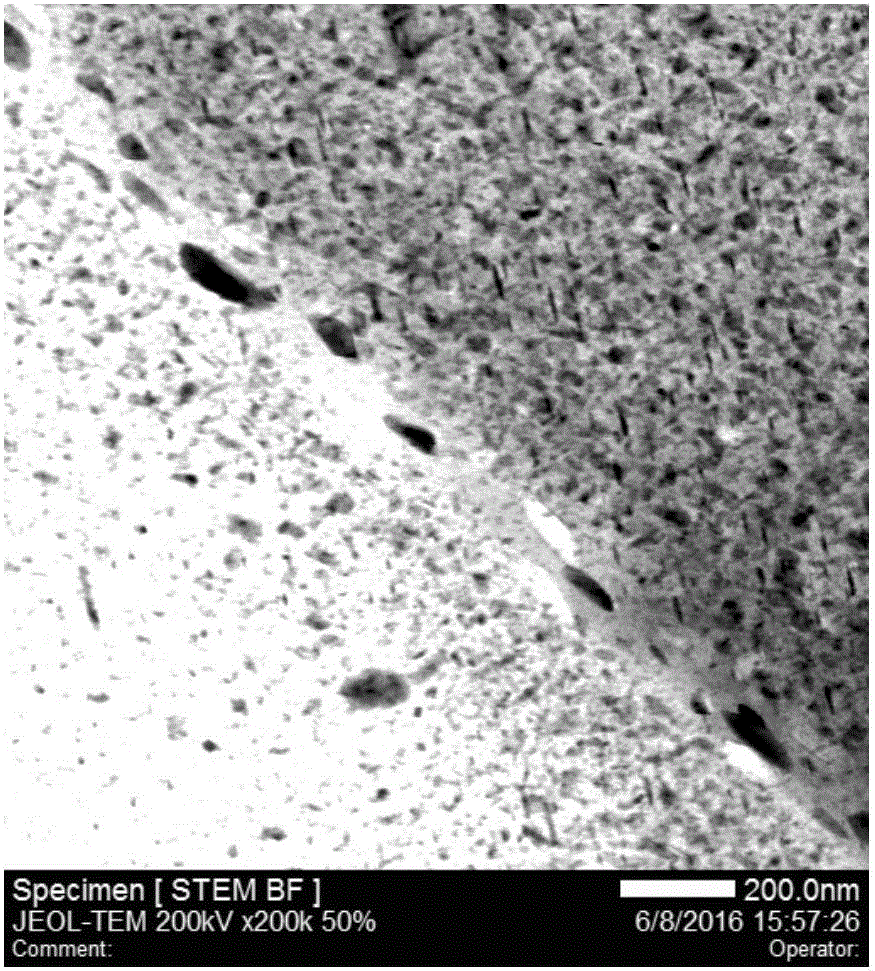

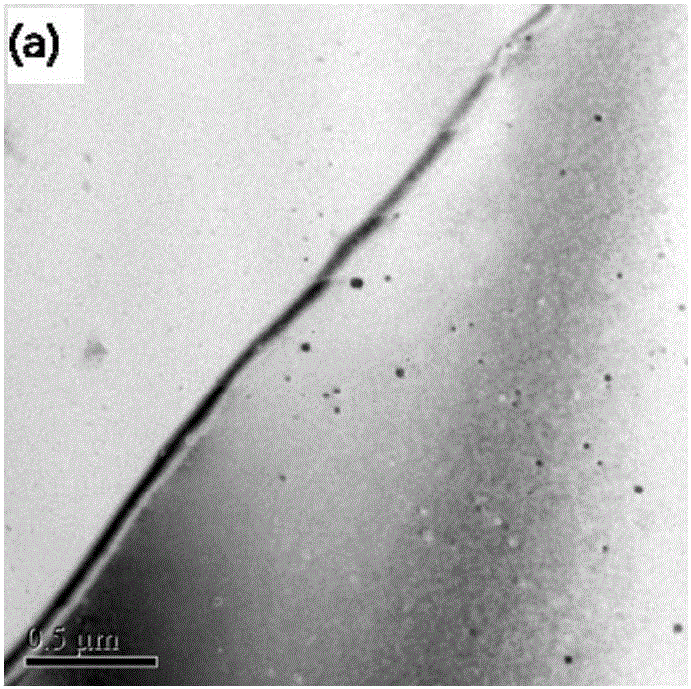

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for producing an aluminum alloy plate for aviation, which includes the following steps:

[0062] Melting: raw materials are prepared according to the chemical composition and mass percentage of the 7150 aluminum alloy standard, wherein the aluminum alloy raw material includes 25% of solid aluminum material, 40% of waste aluminum material, and 35% of electrolyte solution in terms of mass percentage. The aluminum alloy raw material is smelted under the condition of 720°C, and when 50% of the aluminum alloy raw material is melted into molten aluminum, the electromagnetic stirring is turned on, Zn ingot is added, and added by infiltration. After all the aluminum alloy raw materials are melted, other ingredients are added, and the slag is removed and the ingredients are adjusted.

[0063] Casting: pour the melt into an aluminum alloy ingot (480×1560×8650mm).

[0064] Two-stage homogenization treatment: Heat the aluminum alloy ingot to 460°C...

Embodiment 2

[0070] This embodiment provides a method for producing an aluminum alloy plate for aviation, which includes the following steps:

[0071] Melting: raw materials are prepared according to the chemical composition and mass percentage of the 7150 aluminum alloy standard, wherein the aluminum alloy raw material includes 35% of solid aluminum material, 50% of waste aluminum material, and 15% of electrolyte solution in terms of mass percentage. The aluminum alloy raw material is smelted under the condition of 760°C. When 60% of the aluminum alloy raw material is melted into molten aluminum, the electromagnetic stirring is turned on, Zn ingot is added, and added by infiltration. After all the aluminum alloy raw materials are melted, other ingredients are added, and the slag is removed and the ingredients are adjusted.

[0072] Casting: pour the melt into an aluminum alloy ingot (480×1560×8650mm).

[0073] Two-stage homogenization treatment: Heat the aluminum alloy ingot to 470°C at ...

Embodiment 3

[0080] This embodiment provides a method for producing an aluminum alloy plate for aviation, which includes the following steps:

[0081] Melting: raw materials are prepared according to the chemical composition and mass percentage of the 7150 aluminum alloy standard, wherein the aluminum alloy raw materials include: 30% solid aluminum material, 45% scrap aluminum material, and 25% electrolyte. The aluminum alloy raw material is smelted under the condition of 740°C. When 55% of the aluminum alloy raw material is melted into molten aluminum, the electromagnetic stirring is turned on, Zn ingot is added, and added by infiltration. After all the aluminum alloy raw materials are melted, other ingredients are added, and the slag is removed and the ingredients are adjusted.

[0082] Multi-stage purification treatment: the melt is transferred to the holding furnace, and the furnace side Ar and Cl 2The mixed gas is refined, and the melt is degassed through the SNIF degassing equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com