Heating apparatus of washing machine and control method thereof

A heating unit, washing machine technology, applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of prolonging the washing time, wasting washing water, increasing the power consumption of the heater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

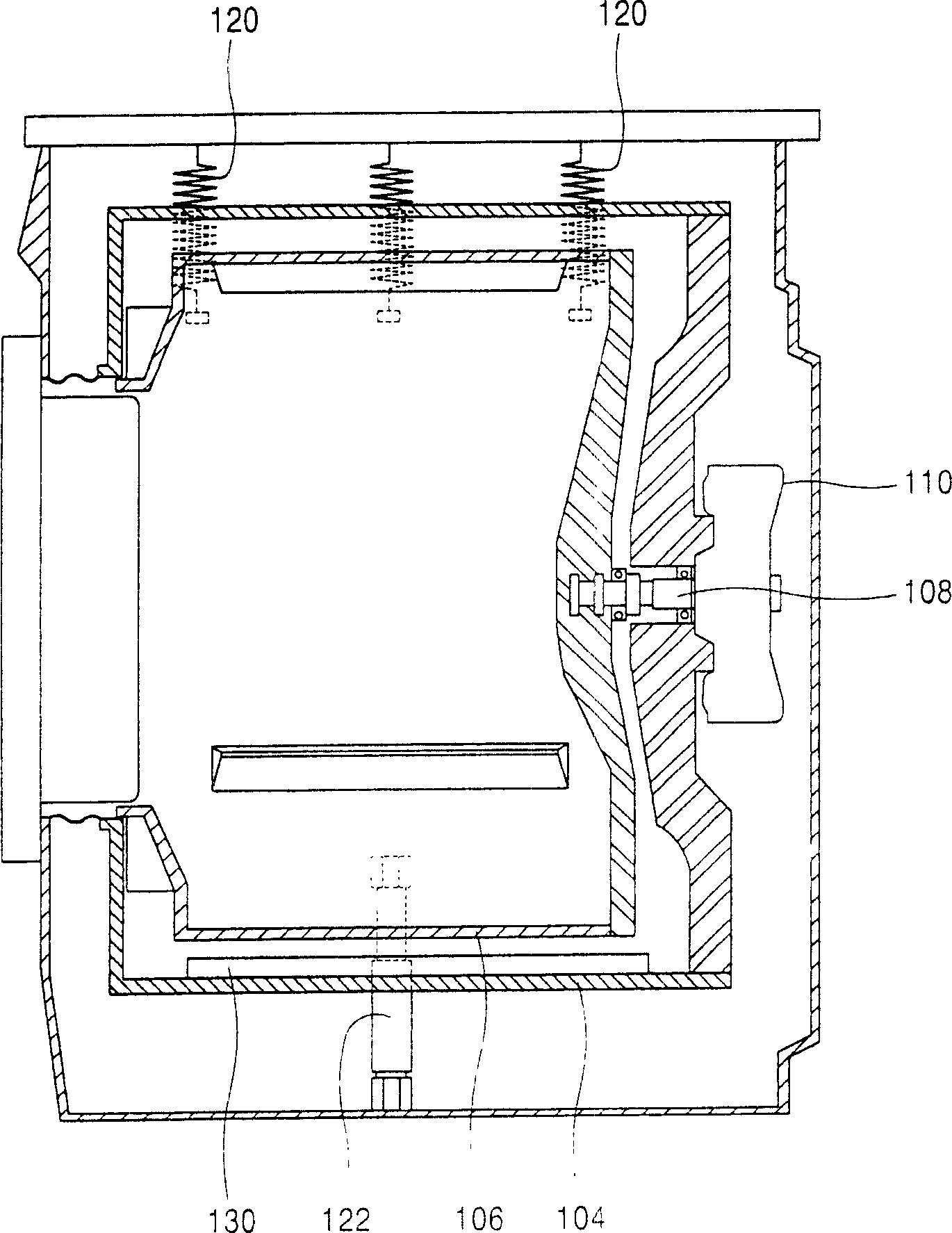

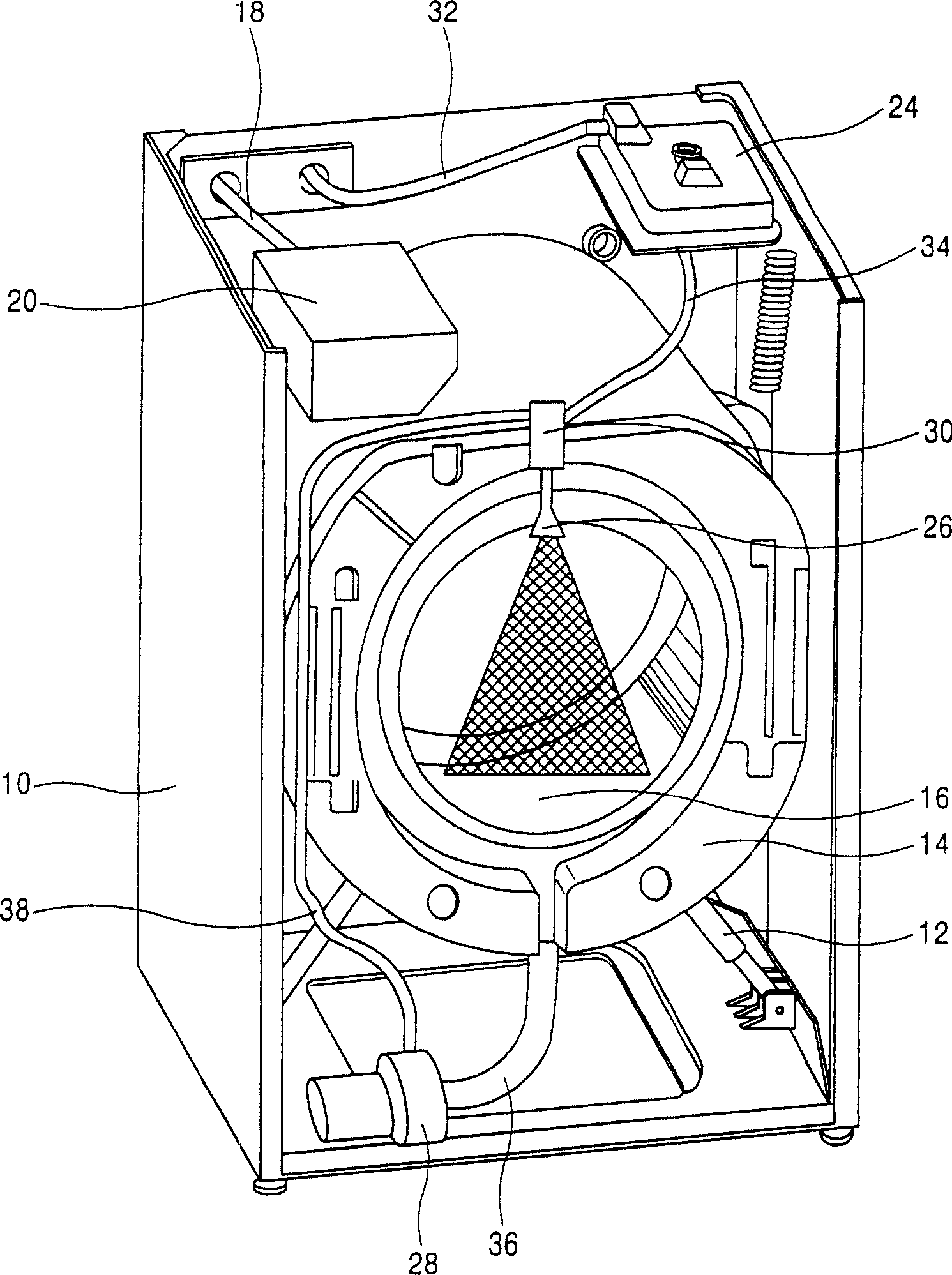

[0024] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0025] figure 2 is a perspective view showing an open front surface of a washing machine according to the present invention.

[0026] A washing machine according to one embodiment of the present invention includes: a housing 10 for forming the appearance of the washing machine; an outer washing tub 14 supported by a shock absorber 12 inside the housing 10 in a vibration-absorbing manner and for storing washing water; An inner washing tub (drum) 16 arranged in the outer washing tub 14 in a rotating manner for washing and dehydrating the clothes; .

[0027] A detergent box 20 connected to a water supply pipe 18 is provided on an upper side of the outer washing tub 14 so as to supply detergent into the outer washing tub 14 together with washing water.

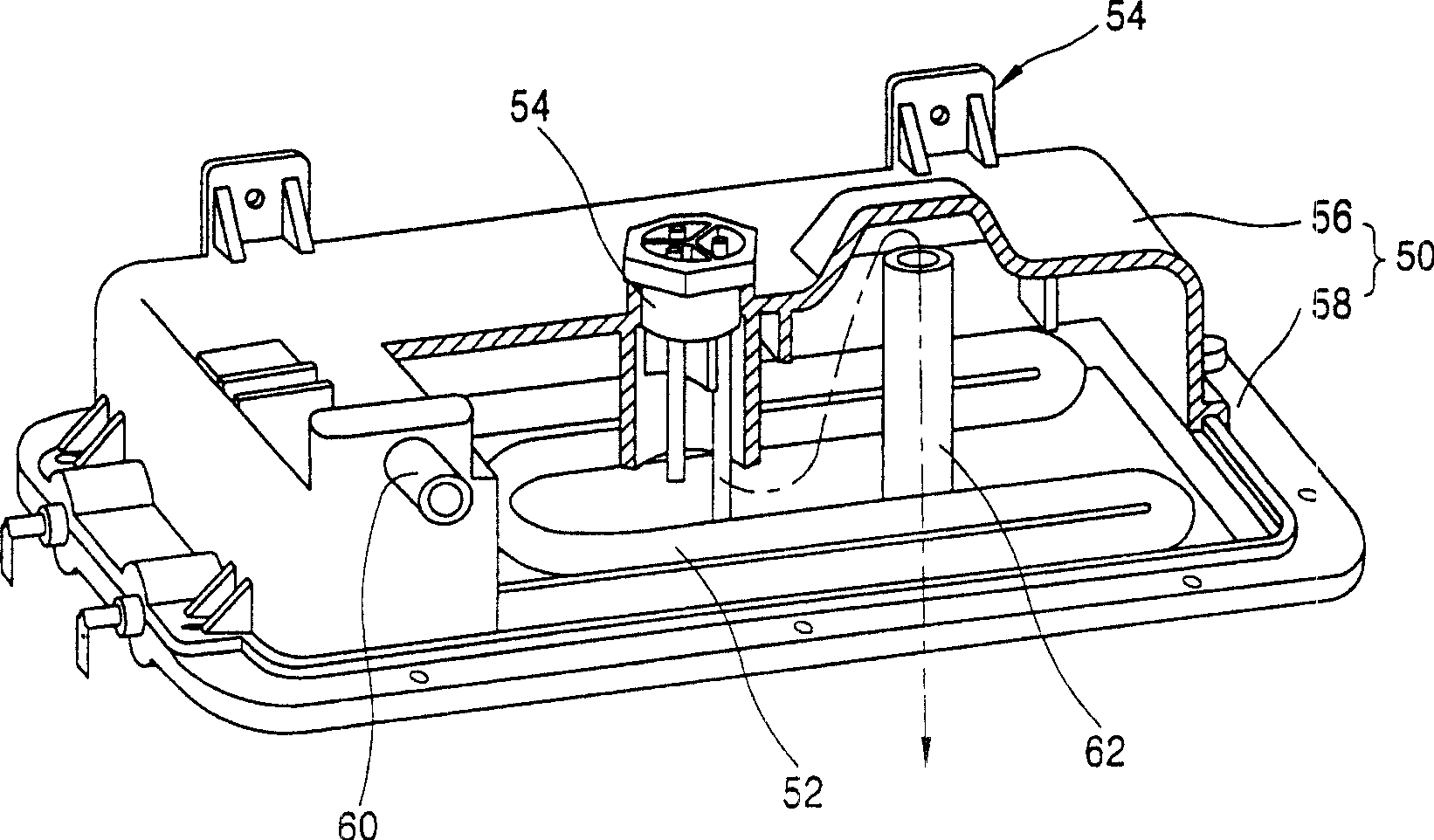

[0028] The heating unit includes a steam generator 24 disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com