Method of producing pseudo boehmite

A technology of pseudo-boehmite and sodium metaaluminate is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, etc., which can solve the problem that the product quality is difficult to guarantee and the production cost is high. , large water consumption and other problems, to achieve the effect of easy product quality assurance, low production cost and small washing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

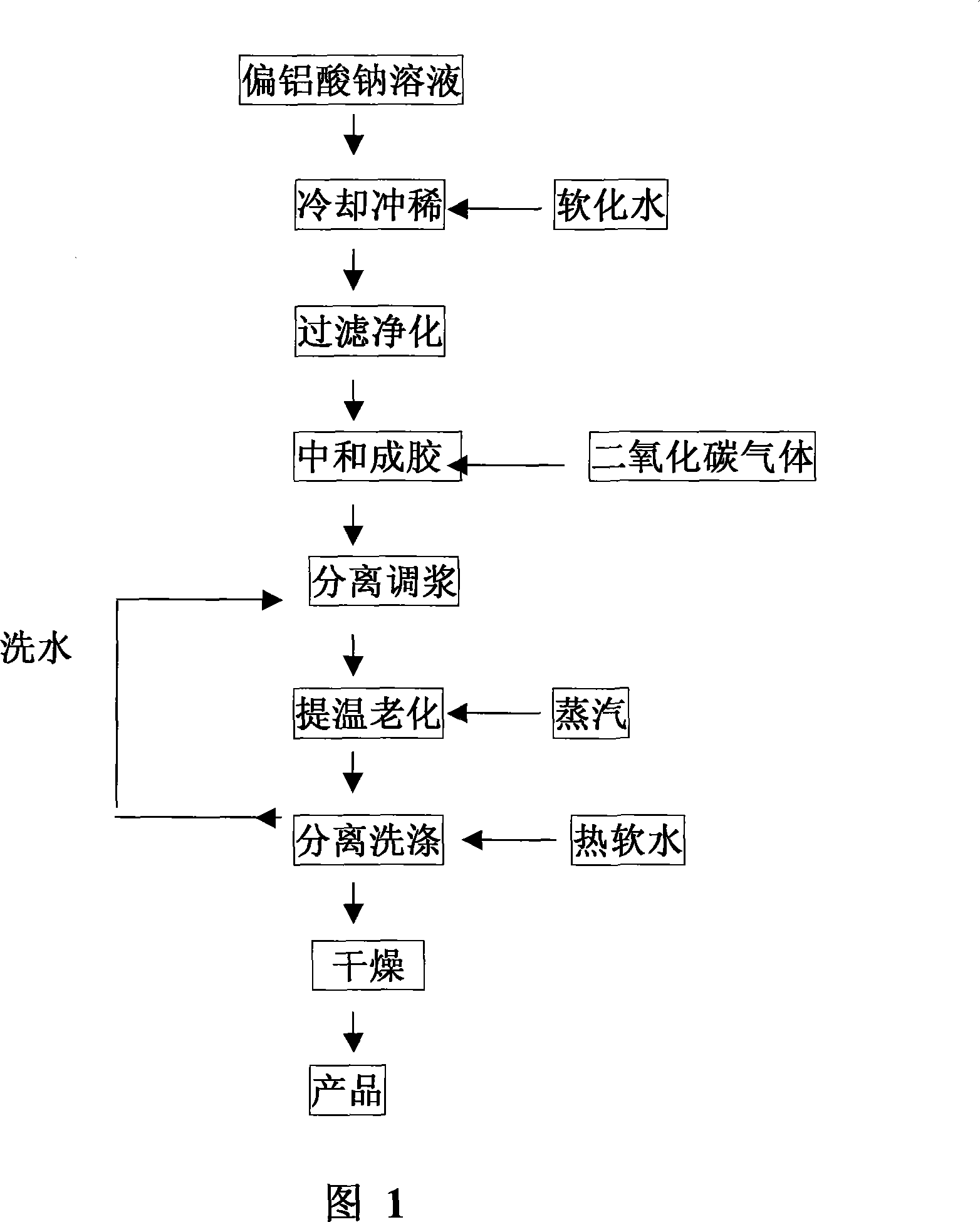

Method used

Image

Examples

Embodiment 1

[0017] Sodium metaaluminate solution 3L (Al 2 o 3 Content is 105g / L, caustic ratio 1.5), adding distilled water or deionized water to dilute to Al 2 o 3 The content is 41g / L, the temperature is cooled to 33-35°C, and the impurities are removed by filtration and purification. Infuse 35-38% CO 2 The gas undergoes rapid carbonation into a gel. The ventilation time was 12.5 minutes.

[0018] Take 1L of the above-mentioned reaction slurry and filter and separate within 10 minutes. The separated filter cake is added to wash water and mixed for beating. 95°C, aging for 4 hours, stirring at 350 rpm. The filter cake was washed with distilled water at 90°C and dried in an oven at a temperature of 80°C to obtain pseudo-boehmite.

Embodiment 2

[0020] Take 1L of the reaction slurry in Example 1 and filter and separate within 10 minutes, add washing water to the separated filter cake and mix it for beating. , raised the temperature to 95°C, aged for 4 hours, and the stirring speed was 300 rpm. The filter cake was washed with distilled water at 90°C and dried in an oven at a temperature of 85°C to obtain pseudo-boehmite.

Embodiment 3

[0022] Get 1L of the reaction slurry of Example 1 and filter and separate within 20 minutes. The separated filter cake is added with washing water and mixed for beating. Warm to 95°C, age for 4 hours, and stir at 400 rpm. The filter cake was washed with distilled water at 92°C and dried in an oven at 90°C to obtain pseudo-boehmite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com