Method for continuously treating heavy metal liquid

A heavy metal, liquid technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution of heavy metals, low efficiency, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

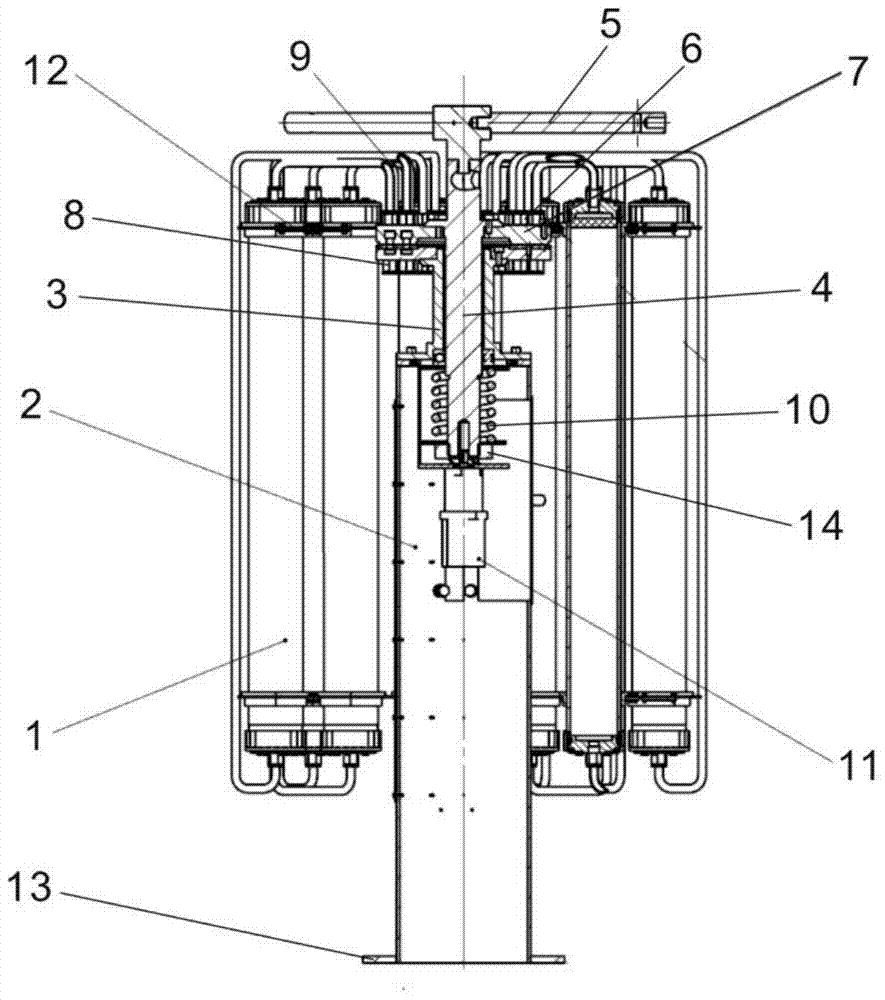

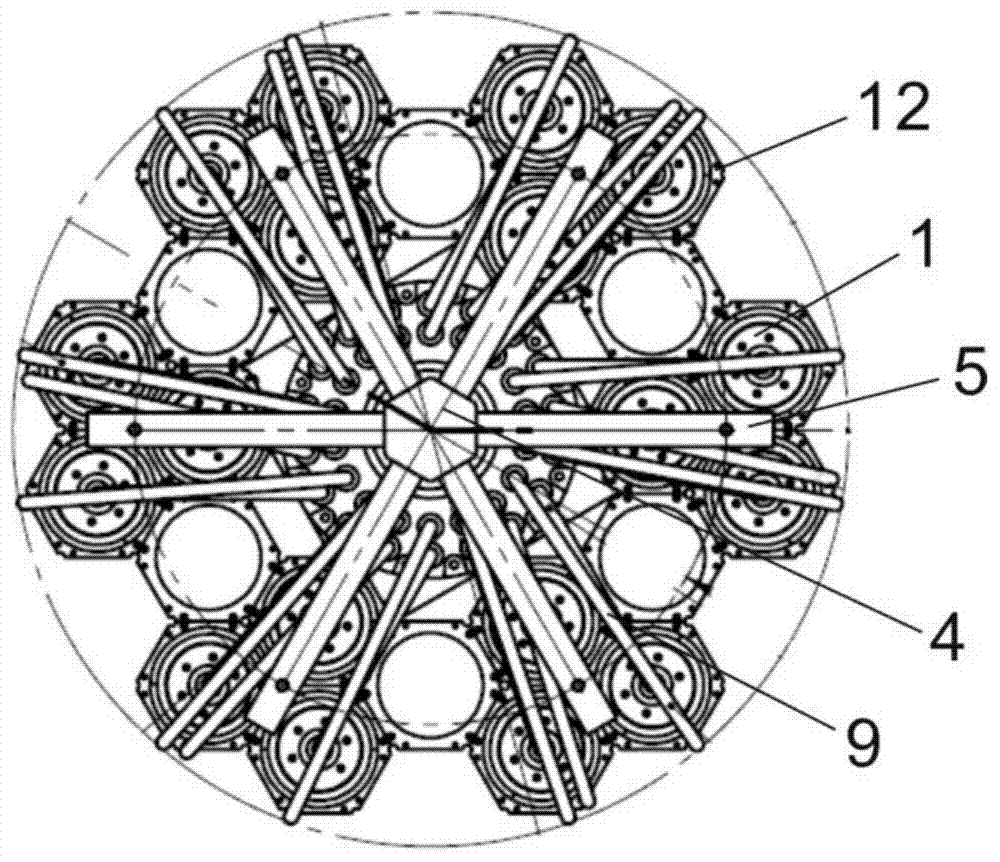

Method used

Image

Examples

Embodiment 1

[0065] The nickel-containing acid wastewater of the smelter, according to the fluctuation of the production process, the nickel content is 30mg / L-200mg / L, the nickel-containing wastewater flows into the sedimentation tank, and the COD and solid particles in the wastewater are rapidly coagulated and precipitated by the coagulation sedimentation method. Reduce the COD to less than 50mg / L, and the total solid content to less than 50mg / L, and transport it into the wastewater buffer tank; the wastewater in the wastewater buffer tank is transported through the pump, and flows into the pH filter through the filter. 1 Electrode wastewater pH adjustment tank: if the pH of the nickel-containing wastewater in the pH adjustment tank is 4.5≤pH 1 ≤9, it flows into the adsorption column; if the pH of the nickel-containing wastewater in the pH adjustment tank 1 1 >9, then stop entering the adsorption column, and use the newly influent acidic wastewater to mix with the nickel-containing wastew...

Embodiment 2

[0083] What is different from Example 1 is that there is no pre-washing area of the pre-washing process in the continuous adsorption process in this embodiment, the regeneration area is a four-column series operation, and the pipeline connection of the regeneration area is: 0.5mol / The ammonia water of L is connected to the panel valve hole A9, flows to the water inlet valve hole C9 of the fixed plate through the pipeline, passes through the fixed plate and the rotating plate, flows out from the water outlet valve hole E9 of the rotating plate, and flows into the adsorption column from the water inlet of the adsorption column 9 through the pipeline Inside. Ammonia water regenerates the silica gel-loaded polymeric amine in the adsorption column to meet the adsorption material, and the regenerated liquid flows out of the water outlet of the adsorption column 9, flows into the water inlet valve hole F9 of the rotating disk, penetrates the fixed disk and the rotating disk, and fl...

Embodiment 3

[0085] The copper-containing acid wastewater of the copper foil factory, according to the fluctuation of the production process, the copper content is 100mg / L~600mg / L, the copper-containing wastewater flows into the sedimentation tank, and the COD and solid particles in the wastewater are rapidly coagulated and precipitated by the coagulation sedimentation method , the COD will be reduced to below 50mg / L, the total solid content will be reduced to below 50mg / L, and it will be transported into the waste water buffer tank; the waste water in the waste water buffer tank will be pumped through the filter and flow into the pH 1 Electrode wastewater pH adjustment tank: if the pH of the copper-containing wastewater in the pH adjustment tank is 1≤pH 1 ≤3, it flows into the adsorption column; if the pH of the copper-containing wastewater in the pH adjustment tank 1 1 >3, then stop entering the adsorption column, and adjust the pH by mixing the newly flowing acidic wastewater with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com