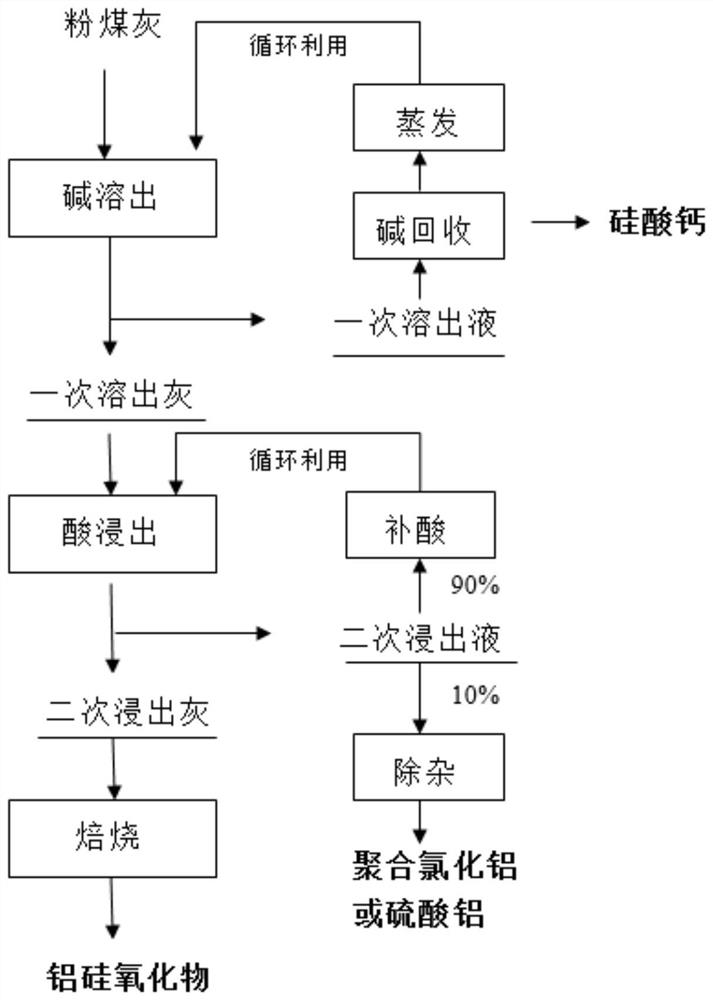

Method for preparing aluminum-silicon oxide from fly ash

A technology of aluminum silicon oxide and fly ash, which is applied in the direction of aluminum compounds, chemical instruments and methods, silicon oxide, etc., can solve the problems of high corrosion resistance of equipment, large slag production, stagnation, etc., and reduce equipment Investment cost, total by-product reduction, and the effect of reducing the amount of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 1) Alkali dissolution treatment

[0095] Add the fly ash to the alkali solution, stir and mix well, and dissolve the amorphous silica and alumina in the glass phase in the fly ash in the alkali solution for alkali dissolution treatment; the alkali dissolution treatment process is controlled The temperature in the furnace is 80°C (usually 70-100°C); the ratio of the mass of fly ash to the volume of alkali solution is 1:5 (usually 1:2.5-6), that is, 5ml of alkali solution is used for every 1g of fly ash Or use 500ml alkali solution per 100g fly ash or carry out alkali dissolution treatment with 5L alkali solution per 1kg fly ash; the alkali solution is a mixed solution of sodium hydroxide, sodium carbonate and water, and the concentration of sodium hydroxide in the alkali solution is 100g / L (usually 50-230g / L), the concentration of sodium carbonate is 5g / L (usually 2-20g / L);

[0096] The quality of the fly ash used in the alkali stripping treatment process in this embodi...

Embodiment 2

[0128] 1) Alkali dissolution treatment

[0129] In addition to the chemical composition of the fly ash raw material is as follows: the mass content of alumina is 45.25%; the mass content of silicon oxide is 44.25%, the mass content of iron oxide is 3.16%, the mass content of calcium oxide is 2.57%; the mass content of magnesium oxide The content is 0.86%, and the mass content of phosphorus pentoxide is 0.01%;

[0130] The ratio of the fly ash mass to the volume of the alkaline solution is 1:4.5; the concentration of sodium hydroxide in the alkaline solution is 150g / L (usually 50-230g / L), and the concentration of sodium carbonate is 10g / L (usually 2- 20g / L); the alkali dissolution treatment temperature is 90°C; the alkali dissolution treatment time is 6.0h; the primary alkali dissolution fly ash (85.4g); the primary alkali dissolution solution (389ml); the silicon dioxide concentration in the primary alkali dissolution solution is Except 32.73g / L, all the other are identical w...

Embodiment 3

[0141] 1) Alkali dissolution treatment

[0142] In addition to the chemical composition of the fly ash raw material is as follows: the mass content of alumina is 43.87%; the mass content of silicon oxide is 48.78%, the mass content of iron oxide is 3.49%, the mass content of calcium oxide is 3.22%; the mass content of magnesium oxide The content is 1.07%, and the mass content of phosphorus pentoxide is 0.24%;

[0143] The ratio of the fly ash mass to the volume of the alkaline solution is 1:3.5; the concentration of sodium hydroxide in the alkaline solution is 80g / L (usually 50-230g / L), and the concentration of sodium carbonate is 18g / L (usually 2- 20g / L); the alkali dissolution treatment temperature is 95°C; the alkali dissolution treatment time is 7.0h; the primary alkali dissolution fly ash (88.7g); the primary alkali dissolution solution (282ml); the silicon dioxide concentration in the primary alkali dissolution solution is Except 44.36g / L, all the other are identical wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com