Medicinal hollow capsules and preparation method and manufacturing equipment thereof

A technology for hollow capsules and manufacturing equipment, which is applied in capsule transportation, pharmaceutical formulations, drug delivery, etc. It can solve problems such as impact on human safety, large discharge of process wastewater, and high pressure on environmental protection, so as to reduce process water consumption, Obvious advantages, thorough sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

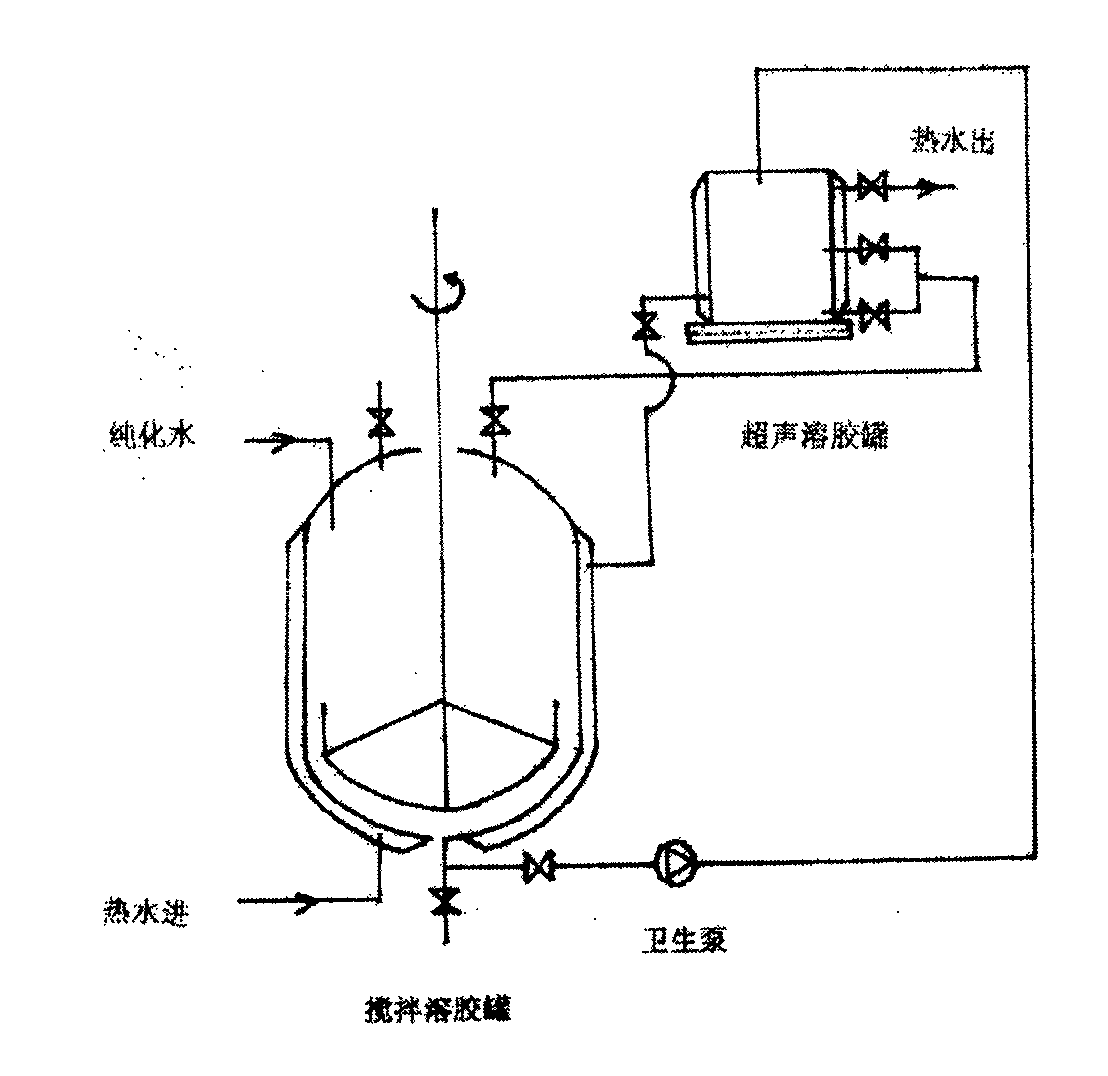

[0028] Small batch production can be carried out directly in the ultrasonic sol tank. After the production system is cleaned, inject 34.5L of purified water into the ultrasonic sol tank, add 15Kg of gelatin, turn on the ultrasonic power supply, first select the low power button, wait for the temperature to rise to 45°C, select the medium or high power button, and vacuum slowly, 30 Minutes to 50 minutes later, after sampling and testing the clarity to pass, the sol process is completed.

Embodiment 2

[0030] Mass production can adopt ultrasonic and variable speed stirring combined sol method. After the production system is cleaned, pour 92L of purified water into the stirring sol tank, add 40Kg of gelatin, and start stirring. The stirring speed can be selected from 30 to 60 rpm. When the temperature rises to 45°C, start the sanitary pump or peristaltic pump, slowly inject the material liquid into the high-level ultrasonic sol tank, turn on the ultrasonic power supply, select the medium or high power button, and slowly pump air under vacuum. After 30 minutes to 50 minutes, after After sampling and testing the clarity is qualified, the sol process is completed.

Embodiment 3

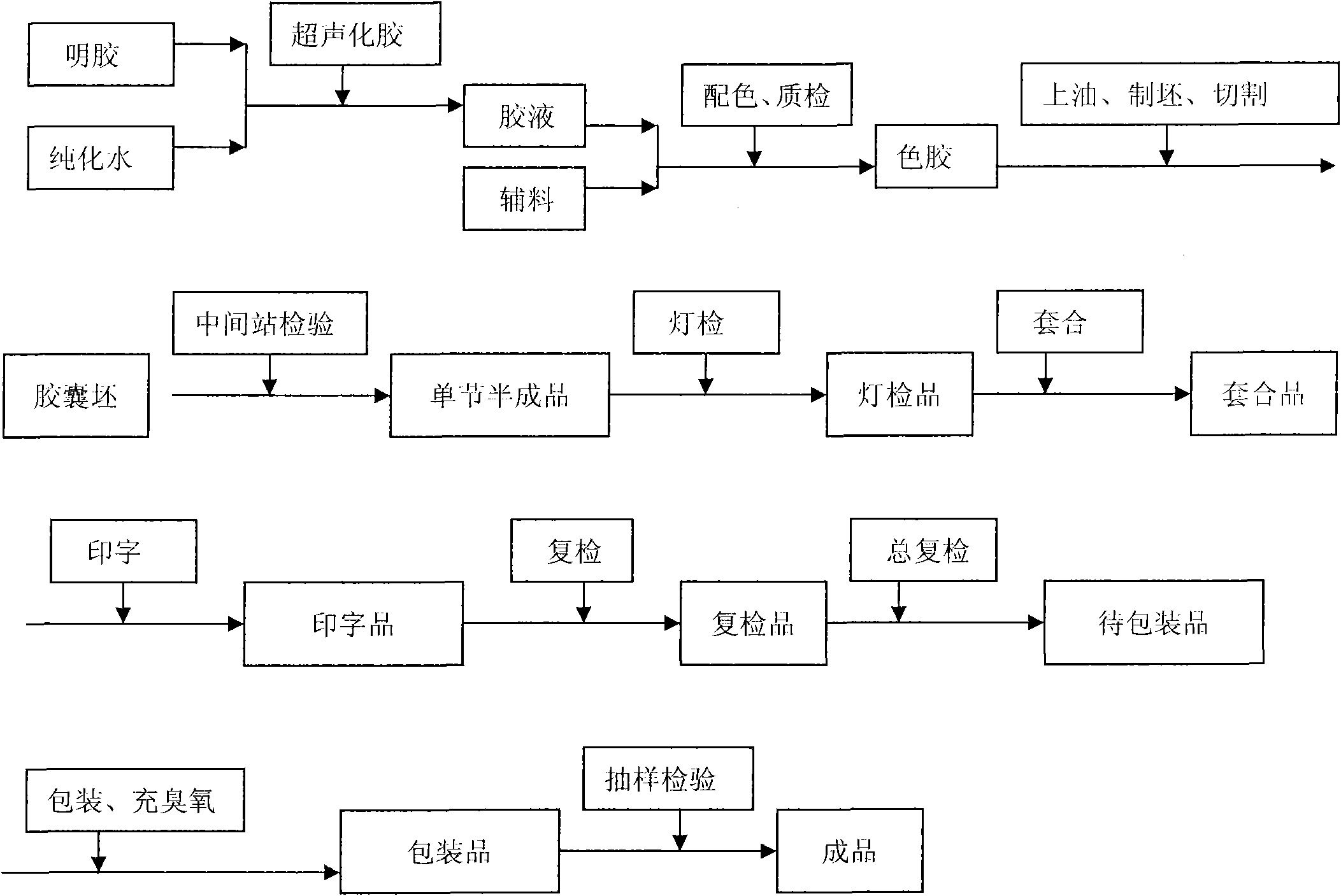

[0032] After the sol is completed, add 120g of sodium lauryl sulfate to the glue, stir well, transfer to the color matching tank in which the cuttings have been dissolved, add food coloring, appropriate amount of titanium dioxide paste, filter, after the glue is defoamed and matured, enter the automation blank making, cutting, fitting and other processes to make hollow capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com