Washing machine provided with ultra-fine bubble generating device

A technology of ultra-fine bubbles and generating devices, which can be applied to other washing machines, washing devices, household appliances, etc., can solve the problems of environmental hazards, human hazards, and increased rinsing times, so as to reduce usage, enhance impact, and improve dissolution rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

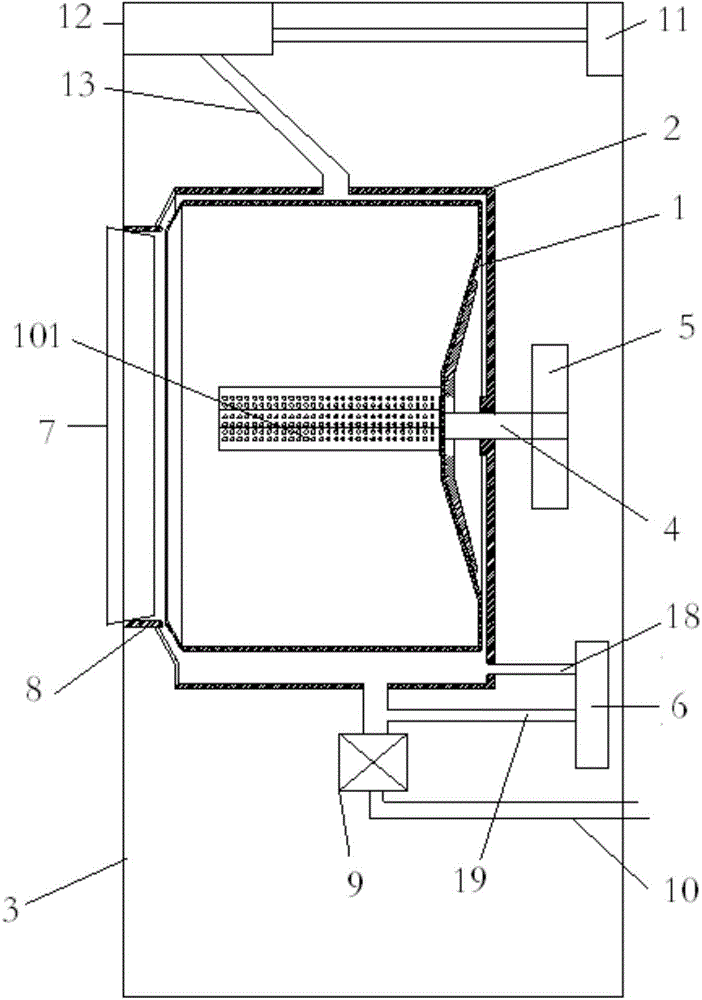

Embodiment 1

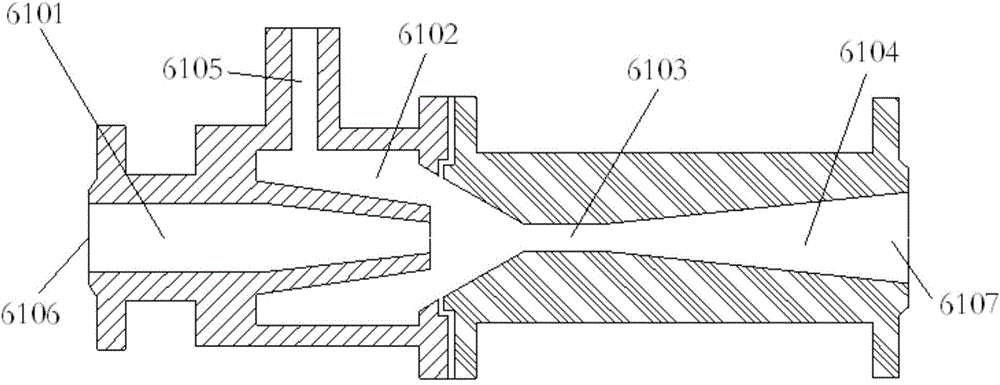

[0048] Such as image 3 As shown, the ultra-fine bubble generating device 6 is an ejector, and the ejector includes a nozzle 6101, a throat 6103 and a diffuser pipe 6104 connected in sequence, and the ejector also has a water inlet 6106, and the water inlet 6106 is located at The head end of the nozzle 6101 and the gas-liquid mixing outlet 6107 are located at the end of the diffuser pipe 6104, and the water inlet 6106 and the gas-liquid mixing outlet 6107 of the jet are respectively communicated with the outer cylinder 2 through pipelines, so that the outer tube 2 The washing liquid in the barrel 2 enters the ejector, and the washing liquid mixed with ultrafine bubbles flows back to the outer barrel 2 . Preferably, the water inlet 6106 is communicated with the drain pipe 10 of the outer cylinder 2 . A booster pump is arranged between the outer cylinder 2 and the water inlet 6106 of the ejector, and a suction chamber 6102 communicated with an air inlet pipe 6105 is provided be...

Embodiment 2

[0053] Such as Figure 4 As shown, the ultra-fine bubble generating device 6 includes a gas-liquid mixing container 6201 and a gas booster 6204. One end of the gas-liquid mixing container 6201 is provided with a gas-liquid inlet, and the other end is provided with the gas-liquid mixing outlet 6209. , the gas-liquid mixing outlet 6209 communicates with the outer cylinder 2, the gas-liquid inlet is connected to one end of the gas-liquid inflow pipeline 6202, and the other end of the gas-liquid inflow pipeline 6202 is the water inlet 62021, The water inlet 62021 communicates with the outer cylinder 2, and the gas booster 6204 communicates with the gas-liquid inflow pipeline 6202 through the gas pipe 6203; The delivery device to the gas-liquid mixing outlet 6209.

[0054] In this embodiment, as a preferred solution, the conveying device includes a rotating rod 6205 and a motor 6206 arranged at one end of the rotating rod 6205 to drive the rotating rod 6205 to rotate, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com