Sulfate wood pulp short-sequence ECF bleaching process X/Z/D-EOP-D or X/D/Z-EOP-D

A short-program, sulfate-based technology, applied in pulp bleaching, pulping with inorganic alkali, etc., can solve environmental hazards and other problems, achieve the effects of reduced water consumption, reduced chlorine dioxide consumption, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

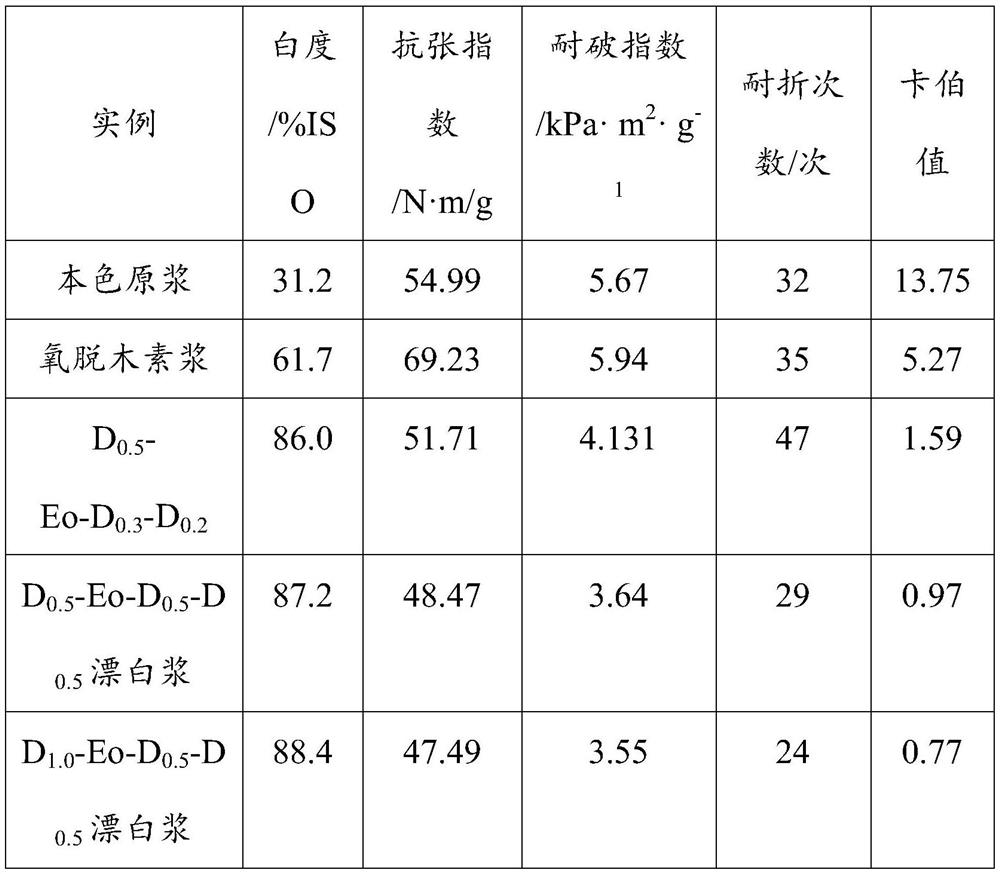

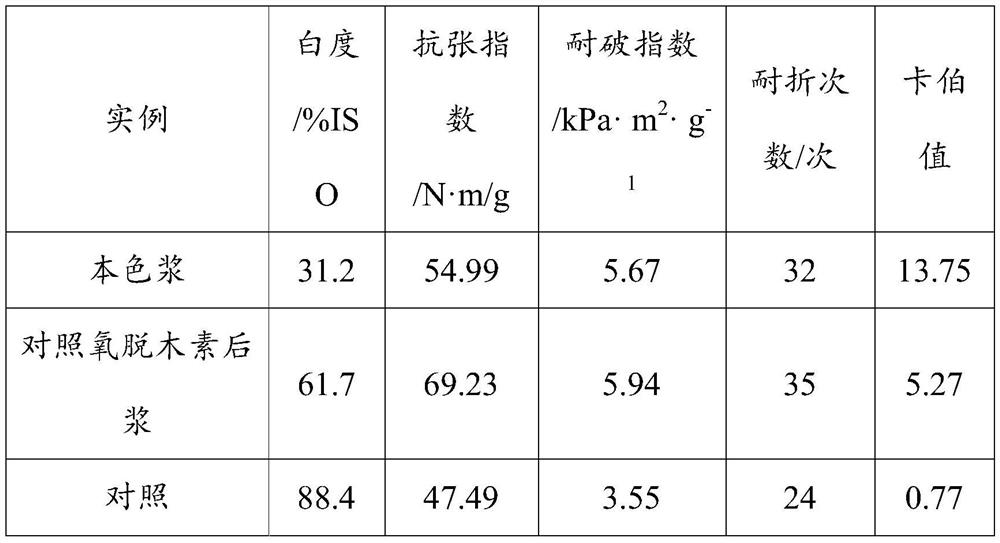

Embodiment 1

[0051] Proceed as follows:

[0052] (1) ECF bleaching: X / Z / D-E was carried out on the eucalyptus kraft pulp after oxygen delignification (the specific preparation method was the same as steps 1) and 2) in Comparative Example 1). OP -D or X / D / Z-E OP -D three-stage bleaching program bleaching.

[0053] First, perform xylanase-assisted bleaching (X), and the process conditions are: the amount of xylanase is 10U / g 浆 , pulp concentration 15%, pH=5, bleaching temperature 55°C, bleaching time 60min; after bleaching, the pulp does not need to be washed directly for ozone bleaching (Z), bleaching temperature 55°C, pulp concentration 15%, pH=2, bleaching The time is 2min, the amount of ethylene glycol is 2%, and the amount of ozone is 0.3%; after the bleaching, the pulp does not need to be washed and directly subjected to chlorine dioxide bleaching (D), and the process conditions are: ClO 2 The dosage is 0.5%, the pulp concentration is 15%, pH=2, the bleaching temperature is 55℃, and...

Embodiment 2

[0061] Proceed as follows:

[0062] (1) ECF bleaching: X / Z / D-E was carried out on the eucalyptus kraft pulp after oxygen delignification (the specific preparation method was the same as steps 1) and 2) in Comparative Example 1). OP -D or X / D / Z-E OP -D three-stage bleaching program bleaching.

[0063] First, perform xylanase-assisted bleaching (X), and the process conditions are: pulp concentration 12%, xylanase dosage 10U / g 浆 , pH=5, bleaching temperature 60°C, bleaching time 60min; after bleaching, the pulp does not need to be washed directly for ozone bleaching (Z), bleaching temperature 60°C, pulp concentration 12%, pH=2, bleaching time 3min, ozone dosage 0.3%, the amount of ethylene glycol is 2%; after the bleaching, the pulp does not need to be washed directly for chlorine dioxide bleaching (D), and the process conditions are: ClO 2 The dosage is 1.0%, the pulp concentration is 12%, pH=2, the bleaching temperature is 60℃, and the bleaching time is 30min; OP Section tr...

Embodiment 3

[0070] Proceed as follows:

[0071] (1) ECF bleaching: X / Z / D-E was carried out on the eucalyptus kraft pulp after oxygen delignification (the specific preparation method was the same as steps 1) and 2) in Comparative Example 1). OP -D or X / D / Z-E OP -D three-stage bleaching program bleaching.

[0072] First, perform xylanase-assisted bleaching (X), and the process conditions are: pulp concentration 11%, xylanase dosage 10U / g 浆 , pH=8, bleaching temperature 70℃, bleaching time 60min; after bleaching, the pulp does not need to be washed directly for ozone bleaching (Z), bleaching temperature 70℃, pulp concentration 11%, pH=3, bleaching time 4min, ozone dosage 0.3%, the amount of ethylene glycol is 2%; after the bleaching, the pulp does not need to be washed directly for chlorine dioxide bleaching (D), and the process conditions are: ClO 2 The dosage is 0.5%, the pulp concentration is 11%, pH=3, the bleaching temperature is 70℃, and the bleaching time is 30min; OP Section trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com