Preparation method for iron phosphate nanosheets

A nano-flaky, iron phosphate technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex and cumbersome operations, large particles, and long time consumption, and achieve high purity, large specific surface area, and accelerated ionization speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

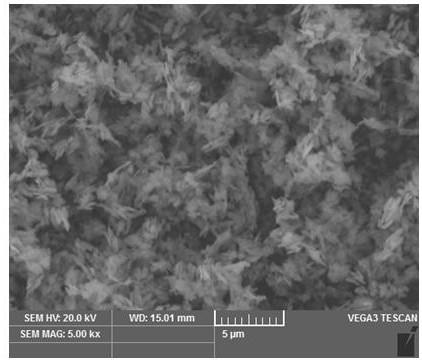

[0028] 1) Take a certain amount of 85% phosphoric acid and deionized water to prepare a 2 mol / L phosphoric acid solution in a volumetric flask, slowly add 9.3g iron black into the phosphoric acid solution at room temperature, and then stir electrically to obtain a reaction solution. The rotation speed is 400r / min, so that the ratio of iron black to phosphoric acid is 1:8.

[0029] 2) Heat the reaction solution obtained in step 1) to 80°C and continue to stir for 4 hours. After the reaction, a white precipitate of ferric phosphate dihydrate is obtained; the white precipitate is subjected to suction filtration, washing and other operations, and then the filter cake is placed in a drum Dry at 110°C in an air drying oven to obtain iron phosphate dihydrate powder.

[0030] 3) Put the ferric phosphate dihydrate powder obtained in step 2) into a muffle furnace for secondary dehydration at a temperature of 700°C, and obtain nano-flaky ferric phosphate after dehydration.

[0031] The ...

Embodiment 2

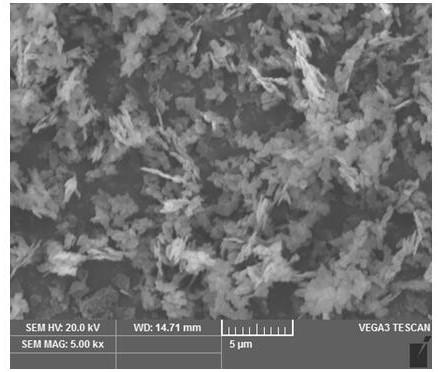

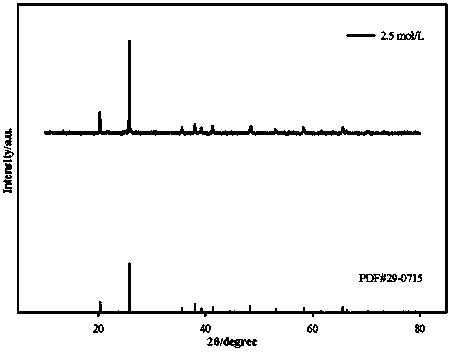

[0034] 1) Take a certain amount of 85% phosphoric acid and deionized water to prepare a 2.5 mol / L phosphoric acid solution in a volumetric flask, slowly add 9.3g iron black into the phosphoric acid solution at room temperature, and then stir electrically to obtain a reaction solution. The rotation speed is 400r / min, so that the ratio of iron black to phosphoric acid is 1:8.

[0035] 2) Heat the reaction solution obtained in step 1) to 80°C and continue to stir for 4 hours. After the reaction, a white precipitate of ferric phosphate dihydrate is obtained; the white precipitate is subjected to suction filtration, washing and other operations, and then the filter cake is placed in a drum Dry at 110°C in an air drying oven to obtain iron phosphate dihydrate powder.

[0036] 3) Put the ferric phosphate dihydrate powder obtained in step 2) into a muffle furnace for secondary dehydration at a temperature of 700°C, and obtain nano-flaky ferric phosphate after dehydration.

[0037] 1....

Embodiment 3

[0042] 1) Take a certain amount of 85% phosphoric acid and deionized water to prepare a 3 mol / L phosphoric acid solution in a volumetric flask, slowly add 9.3g iron black into the phosphoric acid solution at room temperature, and then stir electrically to obtain a reaction solution. The rotation speed is 400r / min, so that the ratio of iron black to phosphoric acid is 1:3.

[0043] 2) Heat the reaction solution obtained in step 1) to 90°C and continue to stir for 6 hours. After the reaction, a white precipitate of ferric phosphate dihydrate is obtained; the white precipitate is subjected to suction filtration, washing and other operations, and then the filter cake is placed in a drum Dry at 110°C in an air drying oven to obtain iron phosphate dihydrate powder.

[0044] 3) Put the ferric phosphate dihydrate powder obtained in step 2) into a muffle furnace for secondary dehydration at a dehydration temperature of 800°C, and obtain nano-flaky ferric phosphate after dehydration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com