Water soluble crude dye refining method based on membrane separation and integration technology

A membrane separation and water-soluble technology, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of loss, large pore size of the first-stage separation membrane, etc., and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

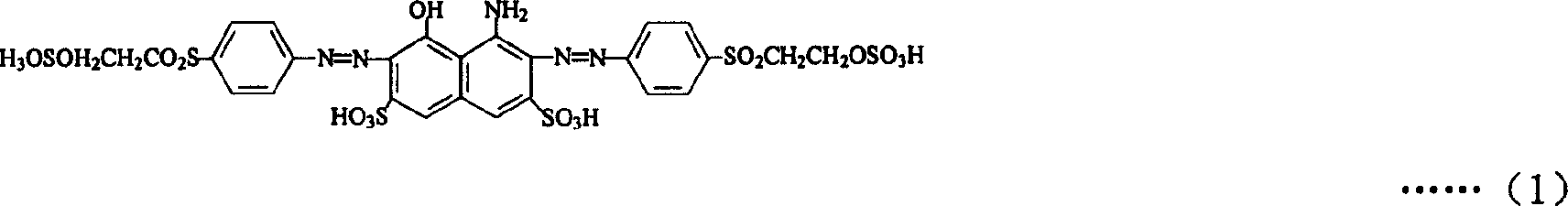

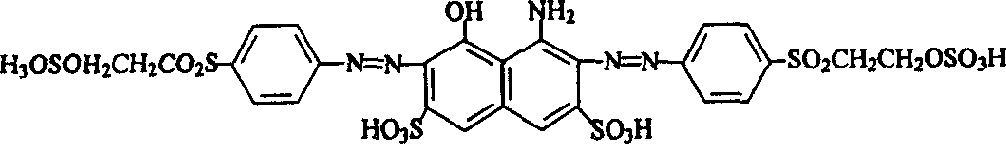

[0030] With structural formula (1)

[0031]

[0032] For example, put the mixed solution of 50kg of crude dye reaction solution containing 10kg of dye and 20kg of the second-stage membrane recovery solution into the first-stage tubular membrane device for desalination reaction. The components of the mixed solution The ratio is (in mass percentage);

[0033] Dye 14.9%

[0034] Sodium chloride 0.5%

[0036] Side reactants 0.4%

[0037] Water 82.38%

[0038] The membrane material of the first-stage membrane separation device is polyethersulfone, the molecular weight cut-off of the membrane is 500-10000, and the membrane area is 0.9m 2 , the operating pressure is 1.0MPa, and the operating temperature is 25°C. During the operation, deionized water was added, and salt water leaked out. After 9 hours, 220kg of salt water leaked out, and then the water was stopped, and the treated dye was concentrated to 40 kg, and the following dye components we...

Embodiment 2

[0055] As the dyestuff (C.I.. Reaction Brilliant Blue 19) of formula (3) will pretreated 10kg crude dyestuff reaction liquid containing 1.43kg dyestuff and 4kg of the second stage membrane recovery liquid, the composition of its mixed solution is as follows:

[0056]

[0057] Dye 10.3%

[0059] Side reactants 0.4%

[0060] Water 86.1%

[0061] The above dye solution is placed in the first-stage tubular membrane device for desalination and concentration operations. The membrane material is polyamide, the molecular weight cut-off of the membrane is 500-10000, and the membrane area is 0.9m 2 , operating pressure 1.0MPa, operating temperature 25 ℃. While adding deionized water during the operation, brine leaked out, then stopped adding water, concentrated to 6kg, after 4.5 hours, 54kg of brine leaked out, and the following dye components were obtained:

[0062] Dye 23.7%

[0063] Sodium sulfate 0.15%

[0064] Side reactants 0.17%

[0065] Wa...

Embodiment 3

[0073] Such as the fluorescent whitening agent of formula (4)

[0074]

[0075] Its components are as follows:

[0076] Fluorescent whitening agent 1.2%

[0077] Sodium Chloride 2.0%

[0078] Side reactants 0.2%

[0079] Water 96.6%

[0080] 4060 g of the pretreated reaction aqueous solution containing 48 g of fluorescent whitening agent was placed in a tubular membrane device. The membrane material is polyethersulfone, the molecular weight cut-off of the membrane is 500-10000, and the membrane area is 0.02m 2 , operating pressure 1.0MPa, operating temperature 30 ℃. After 6 hours, 3800g of salt water was revealed to obtain 200g, and its composition was as follows:

[0081] Fluorescent whitening agent 24.00%

[0082] Sodium chloride 0.3%

[0083] Side reactants 0.03%

[0084] Water 75.67%

[0085] The content of fluorescent whitening agent in the permeate is 0.01%.

[0086] The fluorescent whitening agent suspension treated by the method of the present invention n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com