Preparation method of indium oxide and precursor thereof

A technology of indium oxide and precursors, applied in the field of preparation of indium oxide and its precursors, to achieve the effects of ensuring stability, good environmental protection, and stable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

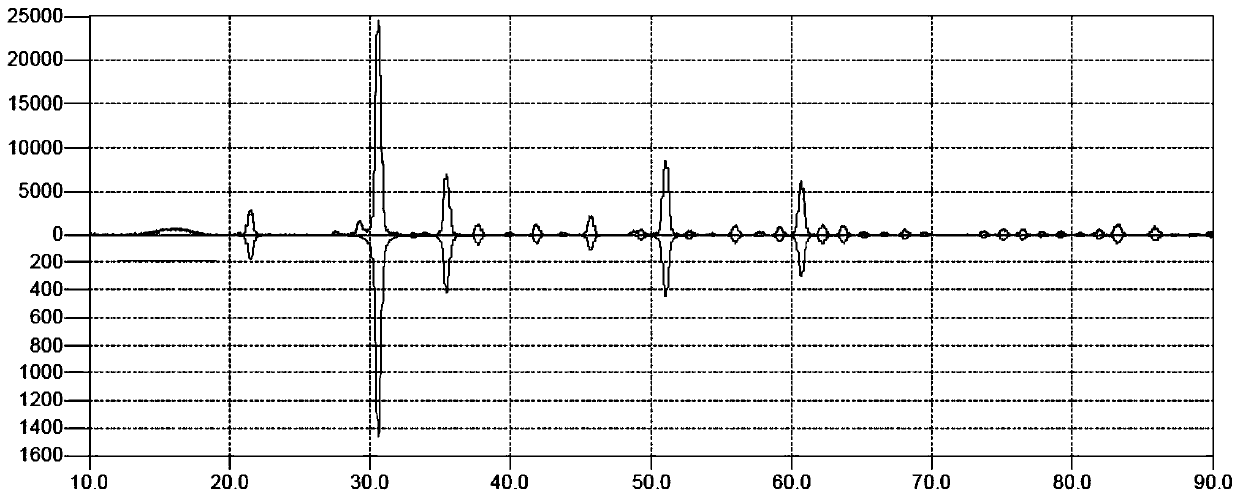

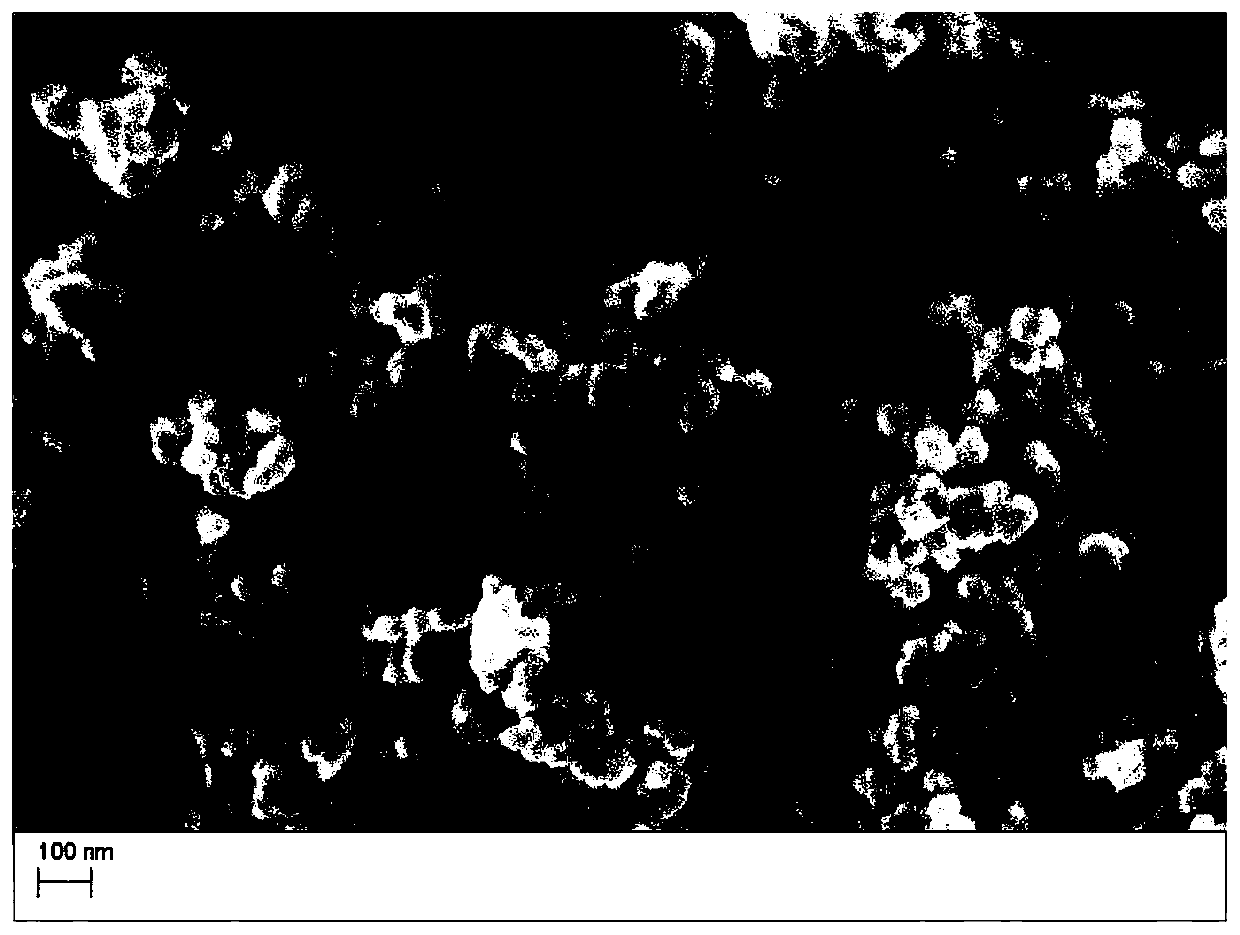

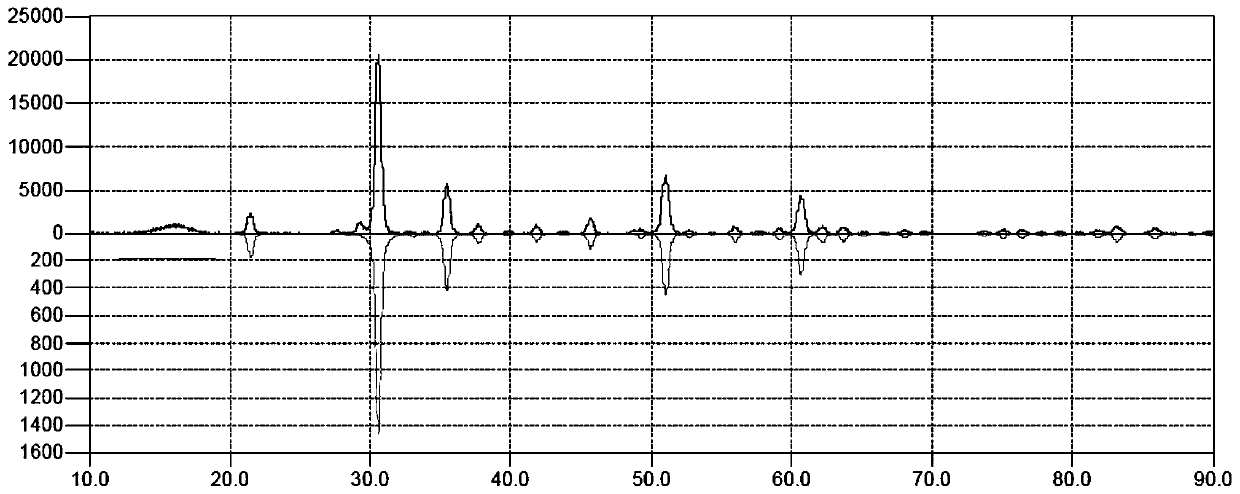

Embodiment 1

[0061] An embodiment of the preparation method of indium oxide of the present invention. The electrolysis device adopted in the preparation method is composed of 3 cathode chambers and 2 anode chambers. The cathode chambers and the anode chambers are arranged alternately with a proton membrane between them. The size of the anode chambers is 230*230*40mm (2.1L). The indoor and indoor dimensions are 230*230*20mm (1.05L), the volume of the anolyte storage tank is 60L, the volume of the catholyte storage tank is 30L, the anode chamber is connected with the anolyte storage tank, and the cathode chamber is connected with the cathode The electrolyte storage tank and the anolyte storage tank are connected; the anode indium plates are made of 4N elemental indium through an automatic casting system, and the effective electrolytic size of the anode plates is 200*80*15mm, which are installed alternately and parallelly in each anode chamber ; Cathode aluminum plates are alternately install...

Embodiment 2

[0063] An embodiment of the preparation method of indium oxide of the present invention. The electrolysis device, negative electrode and anode that this preparation method adopts are all identical with embodiment 1; The ammonium nitrate aqueous solution that the pH value is 5.0-5.5, concentration is 1.0mol / L adds catholyte storage tank, anode chamber and cathode chamber respectively, Then heat the anolyte and catholyte to 40°C, turn on the power, and set the current density to 800A / m 2 , put the anolyte between the anode chamber and the anolyte storage tank at a distance of 0.75m 3 / h speed circulation, ammonium nitrate aqueous solution is transported from the catholyte storage tank to the cathode chamber at a speed of 1.5L / h, and hydrogen peroxide is transported to the cathode chamber at a speed of 0.030mol / (A h), while the catholyte passes through the cathode chamber The overflow port of the anolyte enters the anolyte storage tank, and when the solid content of the anolyte ...

Embodiment 3

[0065] An embodiment of the preparation method of indium oxide of the present invention. The electrolysis device, cathode and anode that this preparation method adopts are all identical with embodiment 1; The ammonium nitrate aqueous solution that pH value is 4.0-4.5, concentration is 2.5mol / L adds catholyte storage tank, anode chamber and cathode chamber respectively, Then heat the anolyte and catholyte to 40°C, turn on the power, and set the current density to 1800A / m 2 , put the anolyte between the anode chamber and the anolyte storage tank at 1.7m 3 / h speed cycle, the ammonium nitrate aqueous solution is transported from the catholyte storage tank to the cathode chamber at a speed of 3.0L / h, and the hydrogen peroxide is transported to the cathode chamber at a speed of 0.038mol / (A h), while the catholyte passes through the cathode chamber The overflow port of the anolyte enters the anolyte storage tank, and when the solid content of the anolyte is about 5wt% after electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com